www.amp-research.com

1/11

IM2770 rev 06.08.10

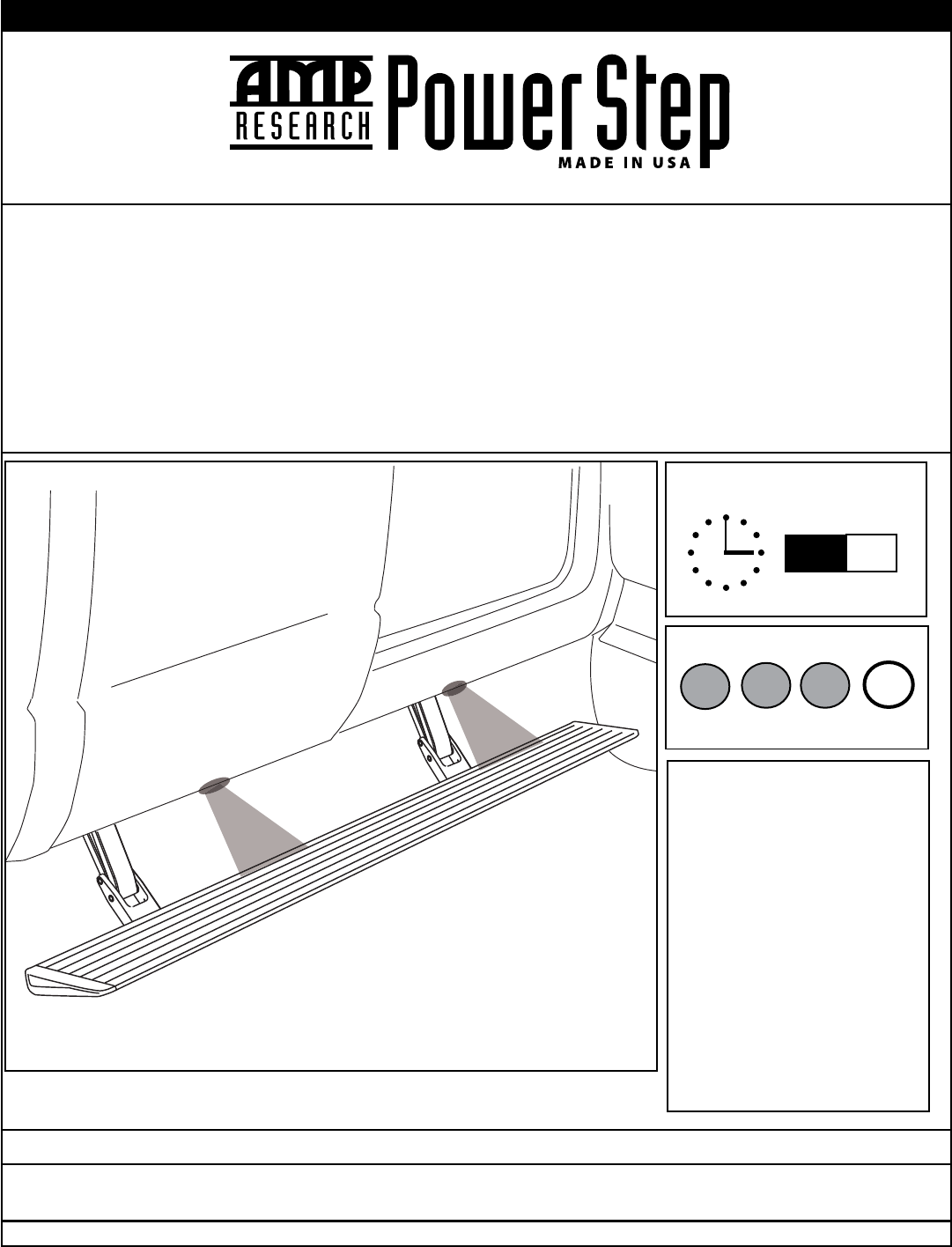

INSTALLATION GUIDE

APPLICATION MODEL YR AMP PART #

Dodge Ram Quad Cab 1500 2002 - 2008 75101-01A

Dodge Ram Quad Cab 2500/3500 2003 - 2009 75101-01A

Dodge Ram Mega Cab 2006 - 2009 75118-01A

4

TOOLS REQUIRED

q Safety goggles

q Measuring tape

q Flat blade screwdriver

q Phillips head screwdriver

q Right angle drill

q 1/8” drill bit

q 13 mm socket

q Ratchet wrench and extension

q Soldering iron

q Wire crimpers

q Wire stripper / cutter

q Corrosion inhibiter

q 3/16” hex key wrench (allen wrench )

q 1/8” hex key wrench (allen wrench)

q 4 mm hex key wrench (allen wrench )

q Pop rivet tool

q Electrical tape

INSTALLATION TIME

1

2 3

4

SKILL LEVEL

4= Experienced

3:00

hrs

AMP RESEARCH TECH SUPPORT 1-888-983-2204 (Press 2)

Monday - Friday, 6:00 AM - 5:00 PM PST

Designed and manufactured by AMP Research

®

. Patent Number 6,830,257; 6,641,158; 6,834,875; 6,938,909; 6,942,233; 7,007,961; 7,055,839; 7,163,221;

7,367,574; 7,380,807; 7,398,985; 7,413,204; 7,487,986. Other US and Worldwide patents pending. Made in USA © 2010 AMP Research

5-year limited warranty. Professional installation is recommended.

www.amp-research.com

2/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

INSTALLATION GUIDE

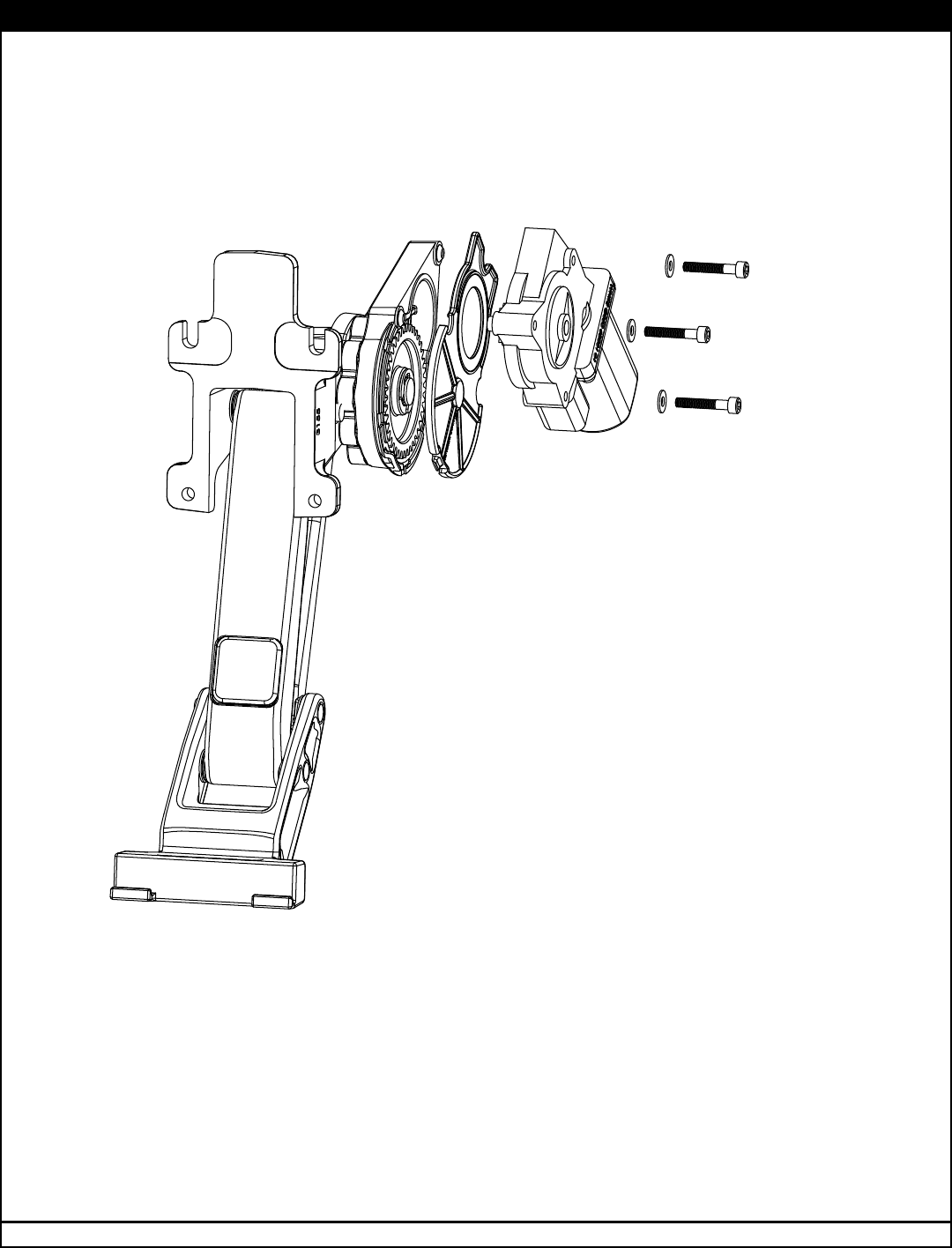

Attaching motor to linkage assembly

The motors need to be installed before continuing with the rest of the Power

Step install.

EXPLODED VIEW

19-03129-11 Motor

19-03179-90 Socket cap screw

19-03133-90 Washer

CAUTION: HANDLE WITH CARE.

To insure our customers receive all components with full integrity, we pack

the motors seperate from their linkage assemblies. This requires that the

installer position and fasten the motor before continuing with the install.

Please follow the instructions below and handle the assembly carefully.

CAUTION: Dropping the assembly or any excessive impact MAY cause

damage to the motor.

Instructions:

1. Position the gear cover in place as shown if not already in place.

2. Seat motor into position on the three mounting bosses. This may require

an adjustment of the gear by moving the swing arms.

3. After seating into place, fasten the motor with the three motor mount

screws with T30 Torx. Tighten screws to 80 in-lbs (9N-m). Do not over

torque.

www.amp-research.com

3/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

1

x2

Running board assembly

3

10-02820-10 (Quad Cab)

10-02820-11 (Mega Cab)

Driver Rear Bracket

4

10-02821-10

Passenger Rear Bracket

2

x2

10-02819-10

Front Bracket

7

19-02774-91

Wire Harness

PARTS LIST AND HARDWARE IDENTIFICATION

8

19-03297-93

Controller

DRIVER REAR BRACKET

PASSENGER REAR BRACKET

6

10-02814-16

Motor Linkage

x2

5

10-02815-16

Idler Linkage

x2

C

E

D

B

A

(A) 19-03225-11 End cap left (x1)

(B) 19-03225-12 End cap right (x1)

(C) 19-02663-90 T-nut insert (x2)

(D) 19-03236-90 Socket cap screw (x2)

(E) 19-03237-90 Nut plate (x2)

20-03314-XX

www.amp-research.com

4/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

9

x8

19-02781-90

Hex Bolt

10

x4

19-02782-90

Hex Bolt

11

x8

19-02802-90

Socket Cap Screw

13

x4

19-02777-90

Mounting Insert

12

x8

19-02784-90

Blind Rivet

14

x25

19-02805-90

Cable tie (7”)

15

x2

19-03339-90

Cable tie (11”)

PARTS LIST AND

HARDWARE

IDENTIFICATION

17

19-03354-90

Damper Bracket Kit

(Only needed for 1500 Quad Cab)

16

x4

19-03354-90

Posi-Taps™ (Red/Grey)

www.amp-research.com

5/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

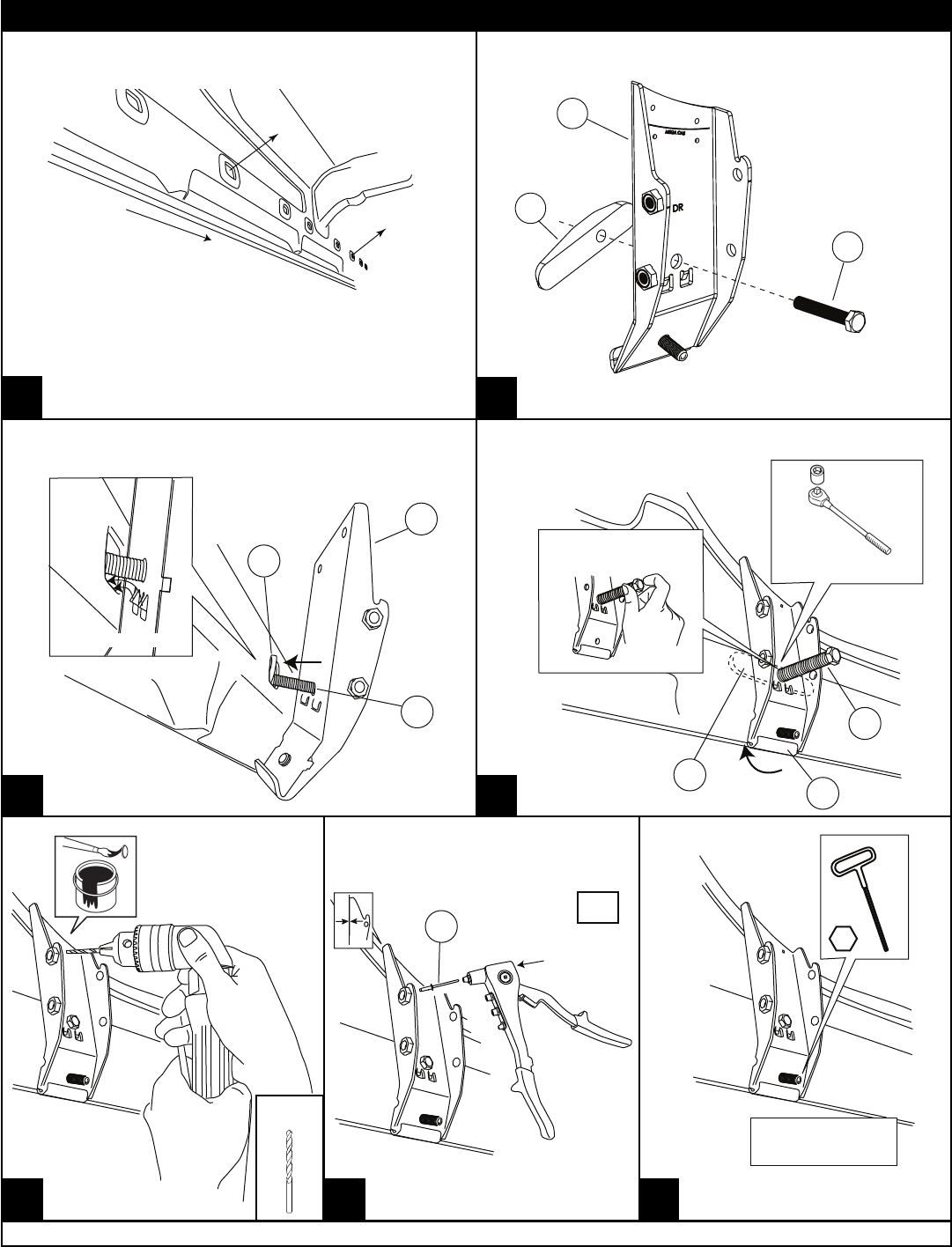

1

3 4

5

2

6 7

FRONT

13

3

10

DRIVER REAR BRACKET SHOWN

Prepare brackets for install

NOTE FOR MEGA CAB:

Remove tape and cut as

indicated for Mega Cab

rear driver bracket if not

already done.

Install rear mounting bracket

13

3

10

TABS REST ON EDGE

TORQUE

16 ft-lbs. (22 N-m)

13 mm

(PULL BACK ON BOLT

WHILE TIGHTENING)

13

3

10

Fasten down rear mounting bracket

After drilling apply

paint to prevent

rusting.

Bracket must be flush with the

sidewall before riveting.

X2

12

TORQUE

1.5 ft-lbs. (2 N-m)

1/8"

Note: Steps 1-8 shown on driver side.

Repeat these steps on passenger side.

Counting large oval sill holes from the front,

remove covering (plug or tape) from the

below indicated mounting points.

QUAD CAB: 3rd and 7th from the front.

MEGA CAB: 3rd and 8th from the front.

1/8”

www.amp-research.com

6/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

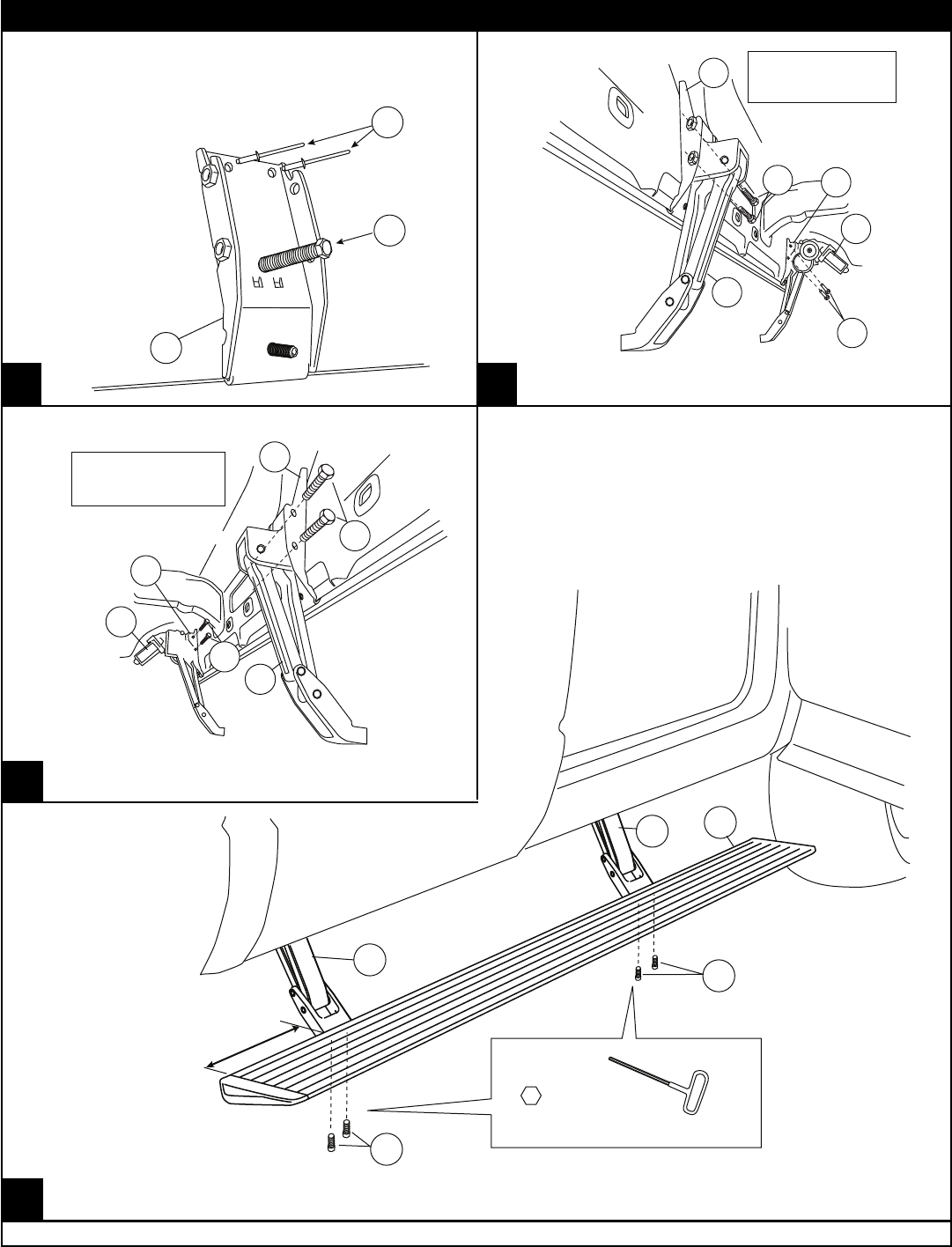

9

10

11

8

Repeat steps 2 thru 6 for front

mounting bracket.

2

10

12

3

2

9

9

5

6

DRIVER SIDE

TORQUE

16 ft-lbs. (22 N-m)

CAUTION: Swing in idler arm can

cause pinch point.

Install rear mounting bracket

4

2

6

9

5

9

TORQUE

16 ft-lbs. (22 N-m)

CAUTION: SWING IN IDLER ARM

CAN CAUSE PINCH POINT

4

Mount step extrusion to linkage assemblies.

Fasten loosely to allow for adjustments.

11"

6

1

5

1

1

1

1

3/16"

TORQUE

10 ft-lbs. (13.5 N-m)

www.amp-research.com

7/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

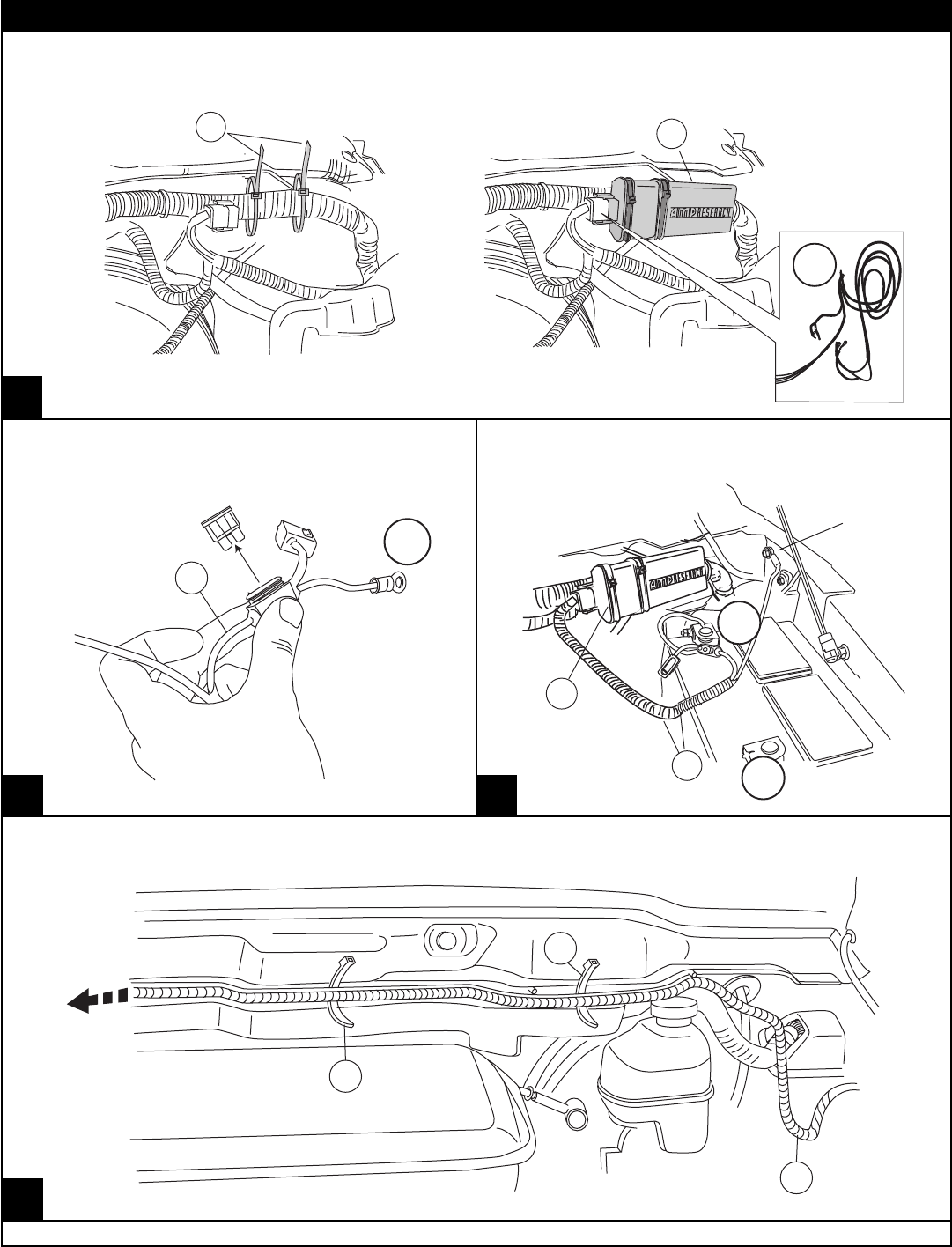

15

13 14

12

Attach 11” cable ties loosely around

harness.

Attach wire harness to the control box.

Slide controller through cable ties. Line up

cable ties with grooves in controller and

tighten.

15

7

8

Remove fuse from Power Step wire harness.

+

7

7

14

14

Route long leg of wire harness to passenger side across fire wall. Secure with tie wraps.

7

_

+

GROUND

Attach power leads, red lead to positive

battery terminal and the black lead to body

ground as shown.

8

Note: Make sure controller con-

nector locking tabs fully engage.

www.amp-research.com

8/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

16 17

18

19

20

7

8

UNTERMINATED WIRES

+

UNDER SIDE OF VEHICLE

7

7

www.amp-research.com

9/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

22

21

23

24

Remove plastic panel beneath steering column.

Remove metal panel revealed by step 21.

Model years 2002-2005 will not have this

panel to remove.

A/C vent ( left of steering column )

Parking break release

Dash light dimmer

25

Locate bundle of wires high

and to the left of diecast

steering column mount.

Note: Bundle of wires leads

toward back of fuel guage

and is located directly above

bundle of wires grounded to

left panel.

Pull wires through and

run them up to the wires

found in the previous

step.

Grey Plug

Remove the cluster and instrument panel to access the grey plug.

www.amp-research.com

10/11

IM2770 rev 06.08.10

AMP RESEARCH POWER STEP – DODGE RAM

Strip 3/8”

Insert and

Tighten

Strip 3/8”

Insert and

Tighten

(Drive/Rear)

(Drive/Front)

27

26

28 29

30

31

VT/WT

VT/WT

VT/YL

VT/YL

VT/GY

VT/GY

VT

VT

TN/RD

VT/WT

TN/Y

VT/YL

VT/OR

VT/GY

TN

VT

7

14

2X BOTH SIDES

7

REINSTALL FUSE

6

7

2X BOTH SIDES

OPEN DOORS TO TEST

Using supplied Posi-

Tap s

TM

splice the Power

Step trigger wires into

their corresponding

door ajar wire. See

steps 26 and 27 for wire

colors.

Note: You may fi nd two VL/YL wires in

bundle. Only one works correctly.

(Pass/Rear) (Pass/Front)

(Drive/Rear)

(Drive/Front)

(Pass/Rear)

(Pass/Front)

Model Year 2004- 2009

Model Year 2002- 2003

amp-research.com

LIMITED WARRANTY

WARNING

Congratulations on the purchase of your

AMP Research Power Step

Here’s what you should know...

OPERATION

The AMP Research Power Step automatically deploys when at least one door opens and automatically retracts under

your vehicle when both front and rear doors close. If resistance or blockage is encountered while the Power Step is

in motion, the drive system is designed to automatically stop. To reset, simply open or close the vehicle door and the

Power Step will resume normal operation.

MAINTENANCE TIPS

The stepping surface and drive mechanism can be wash with mild soap and water using a soft brush or sponge to

dislodge any mud, dirt or accumulated road grime. Rinse with fresh water.

To prevent slipping, avoid applying waxes, lubricants or protectants like Armor All

®

to the step surface.

When washing your vehicle, the Power Steps can be set to remain deployed with the doors closed for easy clean-

ning. Do this...

1 With the Power Step deployed, press and hold the board down with your foot.

2 Close the door while continuing to press down the board. (This will not harm motor.)

3 To reset the Power Step, simply open and close the door. (Repeat for both sides of vehicle.)

CAUTION! BE SURE TO KEEP HANDS AWAY WHEN THE POWER STEP IS IN MOTION.

AMP RESEARCH warrants product to be free from defects in material and workmanship, for terms specied below, provided

there has been normal use and proper maintenance. All remedies under this warranty are limited to the repair or replace-

ment of any item found by the factory to be defective within the time period specied.

If you have a warranty claim, rst you must call our factory at the number below for instructions. You must retain proof of

purchase and submit a copy with any items returned for warranty work. Upon completion of warranty work, if any, we will

return the repaired or replaced item or items to you freight prepaid. Damage to our products caused by accidents, re,

vandalism, negligence,

misinstallation, misuse, Acts of God, or by defective parts not manufactured by us, is not covered under this warranty.

THE WARRANTY TIME PERIOD IS AS FOLLOWS: 5-YEARS FROM DATE OF PURCHASE.

ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE CREATED HEREBY ARE

LIMITED IN DURATION TO THE SAME DURATION AND SCOPE AS THE EXPRESS WRITTEN WARRANTY. OUR COMPANDY SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGE.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specic legal

rights, and you may also have other rights that vary from state to state.

Be sure to read and precisely follow the provided instructions when installing this product. Failure to do so could place the

vehicle occupants in a potentially dangerous situation. After installing or reinstalling, re-check to insure that the product is