NIST GCR 22-032

Life Cycle Environmental Impacts

of Plastics: A Review

Paul Rikhter

Ilayda Dinc

Yirui Zhang

Ted Jiang

Bobby Miyashiro

Shelby Walsh

Ruoyu Wang

Yvonne Dinh

Sangwon Suh

VitalMetrics

This publication is available free of charge from:

https://doi.org/10.6028/NIST.GCR.22-032

NIST GCR 22-032

Life Cycle Environmental Impacts

of Plastics: A Review

Prepared for

U.S. Department of Commerce

Material Measurement Laboratory and Engineering Laboratory

National Institute of Standards and Technology

Gaithersburg, MD 20899-8970

By

Paul Rikhter

Ilayda Dinc

Yirui Zhang

Ted Jiang

Bobby Miyashiro

Shelby Walsh

Ruoyu Wang

Yvonne Dinh

Sangwon Suh

VitalMetrics

This publication is available free of charge from:

https://doi.org/10.6028/NIST.GCR.22-032

March 2022

U.S. Department of Commerce

Gina M. Raimondo, Secretary

National Institute of Standards and Technology

James K. Olthoff, Performing the Non-Exclusive Functions and Duties of the Under Secretary of Commerce

for Standards and Technology & Director, National Institute of Standards and Technology

Disclaimer

Any opinions, findings, conclusions, or recommendations expressed in this publication

do not necessarily reflect the views of the National Institute of Standards and Technology

(NIST). Additionally, neither NIST nor any of its employees make any warranty,

expressed or implied, nor assume any legal liability or responsibility for the accuracy,

completeness, or usefulness of any information, product, or process included in this

publication.

This report was prepared under Contract number 1333ND18DNB630011 Task Order

number 1333ND20FNB730244 titled “The State of Life-Cycle Assessment in Plastics”

between the NIST and Strativia, LLC / VitalMetrics. The statements and conclusions

contained in this report are those of the authors and do not imply recommendations or

endorsements by the National Institute of Standards and Technology.”

i

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Abstract

Global production and consumption of plastics and its deposition in the environment are

growing rapidly, while their life-cycle impacts to the environment are yet to be fully

understood. This study reviews the existing literature with the goal of evaluating the state of

current data and knowledge on plastics’ life-cycle environmental impacts. We identified 98

peer-reviewed journal papers, 25 reports, 8 databases as well as 21 existing reviews on the

environmental impacts of plastics. Our review shows that life-cycle approaches have been

instrumental in gaining new insights on the environmental implications of plastics. Global

life-cycle greenhouse gas (GHG) emissions from plastics, for example, is estimated to be

around 1.7 Gt CO

2

e yr

-1

, which is substantially larger than the GHG emissions from global

aviation. LCAs have also been widely employed in various comparative studies such as

biomass v.s. petroleum-based plastics, single-use plastics v.s. multi-use alternatives, which

often result in counterintuitive outcomes. However, our analysis also indicates that there still

is a paucity of reliable data and tools for conducting LCAs of plastics. In particular, we find

that Asia, the major plastic-producing region, is scarcely covered by existing literature and

databases. In addition, the life-cycle impacts of plastic additives, and the degradation

pathways and associated environmental, human and ecological impacts of plastics are poorly

understood, limiting our ability to gauge the life-cycle impacts of plastics. Furthermore, we

find that a consensus on the allocation of environmental impacts for the recycling and reuse

of plastics is yet to be reached. We identify four major areas of future research including: (1)

developing the method for reliable estimate of the amount of plastics entering the

environment, (2) understanding plastics’ environmental degradation pathways, degradation

byproducts, and their human and ecological impacts, (3) expanding the coverage of life-cycle

inventory data across geographies and additives, and (4) building consensus on key

methodological issues including those around allocation.

Key words

Plastics; life cycle assessment; human and ecological impacts; environmental degradation;

additives.

ii

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Table of Contents

Introduction ..................................................................................................................... 1

Review of Plastics LCA ................................................................................................... 2

2.1. Method ......................................................................................................................... 2

2.2. LCA Databases ............................................................................................................ 2

2.3. LCAs on Plastics by Feedstock Types ........................................................................ 5

2.3.1. Petroleum-based Plastics ....................................................................................... 5

2.3.2. Bio-based Plastics .................................................................................................. 5

2.3.3. Captured CO2-based Plastics ................................................................................ 8

2.4. LCAs on Plastic Materials and Products ..................................................................... 9

2.4.1. Packaging .............................................................................................................. 9

2.4.2. Agriculture ........................................................................................................... 11

2.4.3. Building and Construction ................................................................................... 13

2.4.4. Automotive .......................................................................................................... 14

2.4.5. Consumer Goods ................................................................................................. 15

2.4.6. Electronics ........................................................................................................... 17

2.5. LCAs on Plastics Additives ....................................................................................... 17

2.5.1. Functional Additives ........................................................................................... 18

2.5.2. Colorants ............................................................................................................. 19

2.5.3. Fillers and Reinforcements .................................................................................. 19

2.6. Overall Trend Summary ............................................................................................ 20

Challenges and Gaps in Plastics LCA ......................................................................... 20

Discussion and Recommendations ............................................................................... 23

References .............................................................................................................................. 25

Supporting Information ....................................................................................................... 36

4.1. Terms and Definitions ............................................................................................... 36

4.2. Supplemental Documents .......................................................................................... 37

iii

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

List of Tables

Table 1. Available LCA databases sources, description, and references. ................................. 4

Table 2. Distribution of plastics demands by mass of resin types in 2018 [31]. .................... 36

Table 3. Overview of definitions on plastics. ......................................................................... 37

List of Figures

Fig. 1. Breakdown of bioplastics production capacities and applications [29]. ....................... 6

Fig. 2. Common types of bioplastics and their position in biodegradability and feedstock type

spectra [44]. ............................................................................................................................... 7

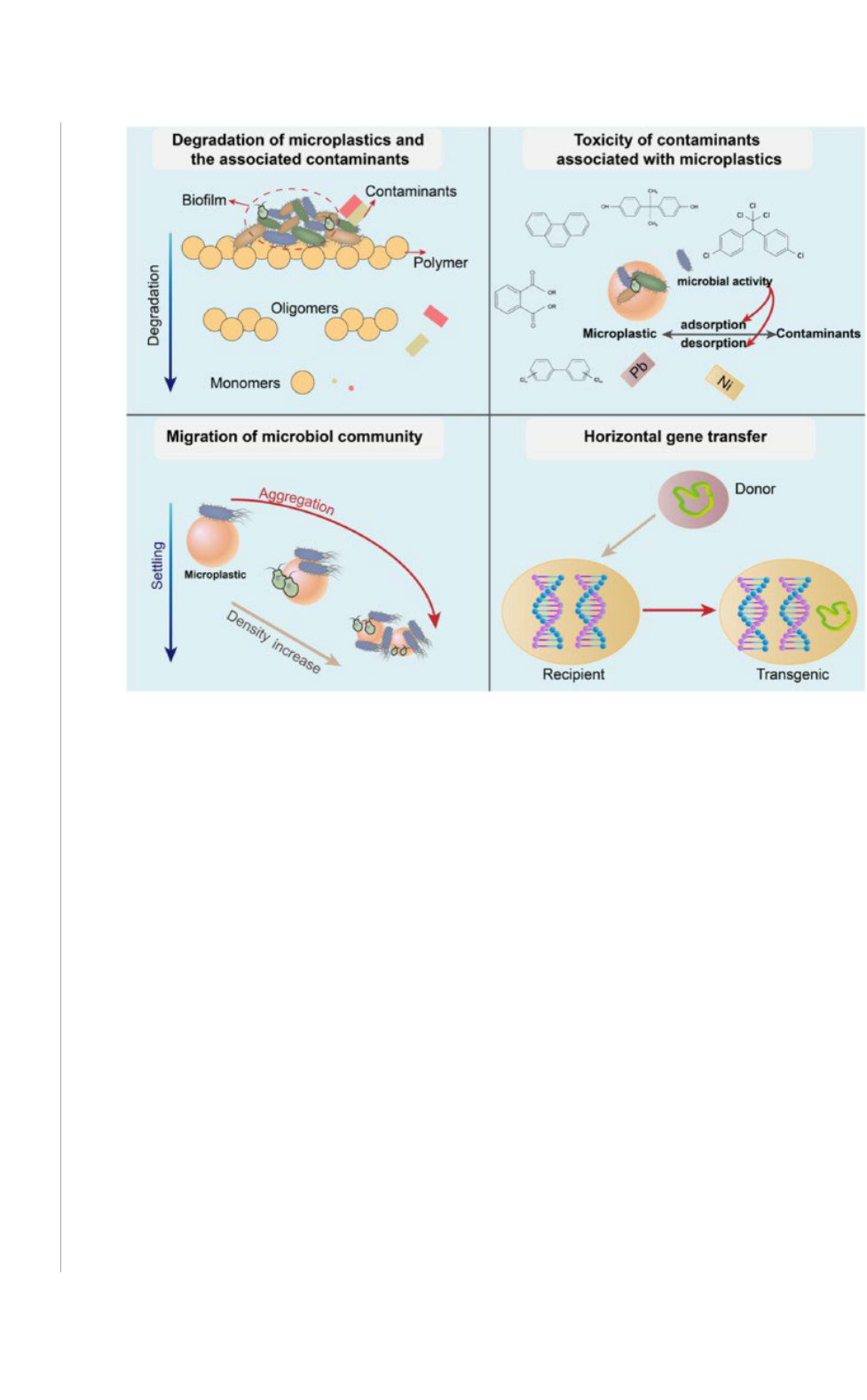

Fig. 3. Implications of microbial habitation and biofilm formation on microplastics [73]. ... 12

Fig. 5. Weathering processes of poorly reversible plastic pollution [38]. .............................. 21

1

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Introduction

The word ‘plastics’ is a colloquial term for a wide range of synthetic or semi-synthetic polymer

materials that are used in a growing range of applications[1]. While the first man-made plastic

was created in 1862, it was not until the 1940s when industrial production of plastics became

possible through the use of fossil fuels as feedstock [1]. Soon after, the growth of the global

plastics market took off in the 1950s [2].

Global plastics market is currently valued at around USD 570 billion and is expected to grow at

an annual rate of 3.2 %. It is estimated that 6,300 Mt of plastics waste has been generated since

the 1960s, around 9 % of which has accumulated in natural environments or landfilled [3]. If the

current production trend continues, roughly 12,000 Mt of plastics waste will be landfilled by

2050 [3].

Plastics serve as a key material in our daily lives. Though plastics have brought many benefits to

human wellbeing and materials welfare thanks to their durability, versatility, and low cost, the

production, consumption, and end of life management of plastics have raised environmental

concerns ranging from persistence in the environment, marine debris, human health risks,

greenhouse gas emissions, among others [4-9].

One of the approaches employed by various studies to measure the environmental and human

health impacts of plastics is Life Cycle Assessment (LCA) [10-13]. LCA is a science-based

approach that quantifies the environmental impacts of products across their life cycle including

extraction of raw materials, manufacturing, transportation, consumption, and disposal [14-16].

However, our ability to understand the life-cycle environmental impacts of plastics hinges upon

the availability and quality life cycle inventory (LCI) data and impact assessment methods. This

study aims to review existing databases, literature, and recent activities related to LCAs of

plastics with the goal to evaluate whether the body of knowledge and data accumulated in the

literature and existing databases provide a sufficient basis for understanding plastics' life-cycle

environmental impacts. We will also identify the key challenges and gaps in current studies,

standards, and tools. Finally, we will discuss the currently on-going initiatives that are aiming to

fill known research gaps.

2

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Review of Plastics LCA

2.1. Method

Relevant research for this review was identified through searching the literature in sources

including Google Scholar, Web of Science, and Google. We used a variety of keyword

combinations to develop a comprehensive list of relevant studies. We used “plastics” and

“polymer” in combination with “LCA,” “life cycle,” “life-cycle” and “life cycle assessment” to

capture the LCAs on plastics. In addition, we used specific application types, material

characteristics, and life-cycle stages to identify the relevant literature that specifically addresses

them, including: “recycling,” “packaging,” “biodegradable,” “bio-based,” “bioplastics,”

“agriculture,” “plasticizers,” “automotive,” “building,” “construction,” “colorants,” “resin,”

“fillers,” “nanoplastics,” “microplastics,” “lightweight,” “single-use,” “fiber reinforced,”

“impacts,” “database,” “materials,” “climate,” and “reusable.” In addition to keywords, searches

also specified the regional interest areas including Europe, the United States, and Asia. The

searched literature was considered relevant if the principles and research it contained discussed

at least one environmental impact or aspect of plastics. The search focused only on the papers

published in or after 1990, but we also included highly cited articles published prior to 1990, if

relevant to this review. Databases and reports that were determined relevant but not covered by

the keyword searches were manually added to the list. Resulting list of data sources includes 98

peer-reviewed journal papers, 25 reports, 8 databases as well as 21 reviews. See Supporting

Information for a complete list of data sources used in this review.

After finalizing the list, we analyzed each item for its objectives, main findings, and key

discussion points. The main topics covered by the list of sources collected include:

environmental characteristics of plastics (46 references), life cycle assessment methods (5

references), databases (3 references), bio-based and biodegradable plastics (16 references),

carbon dioxide-derived plastics (4 references), packaging (15 references), agriculture (11

references), building and construction (11 references), automobiles (13 references), consumer

goods (8 references), electronics (2 references), functional additives (12 references), and fillers

and reinforcements (6 references).

In the next section, we will provide an overview of plastics LCA, data sources, common material

uses, and impacts to be considered. More details on terms and definitions discussed in the report

are in the Supporting Information. We will first review existing LCA databases and their

coverages of plastics. Following that, we will review the LCAs on plastics by their feedstock

categories and then by application types. Given that the plastics that use various feedstock types

are applied in various sectors, the feedstock-based and application-based reviews are two

different angles to look at the same pool of LCA studies. We reviewed plastics by feedstock

type, highlighted bio-based and captured CO

2

-based plastics in section 3.2, while the following

section, 3.3, covers all feedstock types across various applications.

2.2. LCA Databases

The literature often distinguishes two primary approaches to life cycle inventory (LCI):

processed-based and economic input-output (IO) approaches [17-20]. Processed-based LCA

focuses on the material flows and environmental impacts of every life-stage in the life cycle,

which would generate results with high precision and granularity. However, process-based LCA

requires detailed data for every life-stage, thus requiring significant efforts on data collection, the

3

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

absence of which often leads to incompleteness or “truncation error” [18]. IO-LCA is an

approach based on monetary transactions or economic input-output data to trace along the supply

chain, which covers a wider spectrum of sectors but can only provide sectoral or product group

averages at a lower resolution. Table 1 provides a summary of the most widely used databases

for plastics-related LCA modeling from both process-based and IO-based LCA databases.

Altogether, these databases provide LCIs of several hundred plastics materials with varying

temporal and spatial system boundaries and level of aggregation. These LCI databases can be

applied to various life cycle impact assessment (LCIA) methods that quantify plastics impacts on

climate change, ozone layer depletion, acidification, and various human and ecotoxicological

impacts.

Overall, Europe is better represented by these databases than other continents: 4 of the 8

databases listed have data drawn primarily from European industry and the release year of these

databases ranges from 2003 to 2017, while some of the underlying data may be older. These

databases also differ in the feedstock types and application categories they cover. USEEIO,

CEDA, and the GREET model cover plastics product types including bags, bottles, foams, pipes,

laminated products, and others. On the other hand, Plastics Europe and the US LCI database

cover specific resin and monomer types including PET, HDPE, PVC, LDPE, PP, PS, and others.

However, these databases often have limited coverage in plastics additives and bio-based

plastics.

4

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Table 1. Available LCA databases sources, description, and references.

Source of Data

Description

Plastics Categories Included

Ref.

Additional Information

US LCI database

National Renewable Energy Laboratory (NREL) created the US

Life Cycle Inventory Database to provide gate-to-gate, cradle-to-

gate, and cradle-to-grave accounting for plastics environmental

impacts

Process-based resins and polymers including

PET, HDPE, LLDPE, LDPE, PLA, PP, EPS,

PVC, biodegradable fill, open molding, and

others

[21]

Main datasets were collected between 2003 and

2005. Fuel production data for the U.S. based on

Department of Energy national statistics and

data. The national average U.S. electricity grid

(from the U.S. LCI Database) was used.

Ecoinvent

Life cycle inventory database encompassing around 18,000

processes including energy supply, agriculture, transport,

chemicals, construction, and waste treatment.

Process-based resins and polymer markets

including electronics, agriculture, waste

treatment, extrusion, and industry

[22]

Underlying data were drawn mainly from

European sources.

Plastics Europe

Association of plastics manufacturers in the European plastics

industry.

Process-based resins and polymers including

LDPE, LLDPE, HDPE, PP, PVC, VCM,

PTA, PET, and others

[23]

Most of the datasets can be found as such in

their aggregated form in Simapro industrial

database, and Gabi database (which avoid

conversion and format problems)

Gabi Plastics

Extension Database

Gabi provides life-cycle inventory data on mass plastics (e.g., PE

with various densities, PP, PS), vinyl polymers (e.g., PVC,

PVAL), technical plastics (e.g., ABS, PMMA, PTFE), polyamide

(e.g., PA 6, PA 6.6, PA 6.12), special plastics (e.g., PPS, PEEK,

SMA)

Process-based polymers including vinyl

polymers, technical plastics, polyamide, and

special plastics

[24]

US Environmentally-

Extended Input-

Output (USEEIO)

database

The Environmental Protection Agency (EPA) provides an LCA

database on US products and services. This database includes

datasets for multiple plastics products (e.g., plastic bottles).

Plastics resins and polymers as well as

plastics products including plastic bottles,

foam products, bags, pipes, and others

[25]

USEEIO uses an environmental-extended input-

output (EEIO) LCA model.

Comprehensive

Environmental Data

Archive (CEDA)

CEDA is an extensively peer-reviewed suite of environmentally

extended input-output databases first launched in 2000. These are

designed to assist various environmental systems analyses

including life cycle assessments (LCA), carbon, energy, water,

waste, and toxic impact assessment throughout the supply chain.

Plastics products including plastics and

rubber industry machinery manufacturing,

plastics and resin materials manufacturing,

bottles, urethane and other foam products,

rubber and plastics hoses, and others

[26]

CEDA uses an environmental-extended input-

output (EEIO) LCA model.

CarbonMinds

CarbonMinds has developed a CM.CHEMICAL database from a

regionalized model of the global chemical industry, built from

plant-level. The database provides life cycle inventory datasets for

national averages of consumption, production and per technology.

Process-based, supplier- and country-specific

as well as market average LCIs of feedstock,

resin, intermediate and final petrochemical

materials and products

[27]

CM.Chemical uses sophisticated process

simulations and market intelligence data.

Greenhouse gases,

Regulated Emissions,

and Energy use in

Technologies

(GREET) Model

GREET model is developed by Argonne National Laboratory to

address life-cycle emissions of various fuel-vehicle combinations.

Since plastic is widely used in automobile manufacturing, this

model includes LCA data for plastic resins and products.

Process-based resins and polymers including

ethylene propylene diene monomer (EPDM)

resin, flexible polyurethane foam,

compression molding, and average

transformed plastic products

[28]

LCA data for the majority of the processes in

this model is extracted from the aforementioned

NREL and Plastics Europe databases.

5

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

2.3. LCAs on Plastics by Feedstock Types

Currently there are three types of feedstock categories used for producing plastics

commercially: (1) petroleum, (2) biomass, and (3) captured CO

2

. The majority of the

plastics produced and consumed today are petroleum-based, with only slightly above 1 %

of global plastics produced in 2019 being bio-based [29]. From the following section, we

will review LCAs of plastics that use bio-based and captured CO

2

against petroleum-

based plastics.

2.3.1. Petroleum-based Plastics

A majority of plastics are made of petroleum-based polymers. The Society of the Plastics

Industry in the UK and the Plastics Industry Association in the US classify them into

seven categories: PET, HDPE, PVC, LDPE, PP, PS, and others [30, 31]. Petroleum-based

plastics, also known as conventional plastics, are the most common form of plastic with

production on the order of 350 Mt annually and are responsible for 4 % to 8 % of the

annual global oil consumption [32, 33]. Petroleum-based plastics have replaced other

materials due to its lightweight, corrosion resistance, and ability to process in lower

temperatures. As demand for plastics continues to increase, concerns for polymers to leak

from waste streams and not degrade has increased [33]. The slow degradation of

petroleum-based plastics characteristics is favorable for transportation, storage, and use,

but not for disposal [5, 33].

Not surprisingly, given the volume of production, the life-cycle environmental impacts of

petroleum-based plastics are reported to be substantial. A recent study on life-cycle GHG

emissions from plastics, for example, showed that conventional plastics generate 1.7 Gt

CO

2

e yr

-1

over their life-cycle [9]. This level of emission rate is substantially higher than

the direct annual GHG emissions from global aviation.

2.3.2. Bio-based Plastics

Bio-based polymers can be generally grouped into two types, (1) polymers synthesized

by living organisms (natural or bio-engineered) and (2) polymers obtained from bio-

based monomers [34]. An example of the first type is poly(hydroxyalkanoate) (PHAs),

and an example for the second type is polylactic acid (PLA) [34]. These two polymers are

the two most studied bio-based and biodegradable plastics materials [35]. Both materials

are produced from renewable sources, such as corn (maize) and sugarcane [35]. Their

mechanical properties are comparable to other commodity plastics, and both materials are

found to have a simpler and faster degradation mechanism due to their renewable

feedstock [35]. However, some bioplastics’ properties are different, and as such, their

applications and sector focus differs from conventional plastics. The most common

replacement of conventional plastics occurs in packaging, consumer goods, and textiles

(Figure 1).

6

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Fig. 1. Breakdown of bioplastics production capacities and applications [29].

However, it is worth noting that not all bio-based polymers are biodegradable [34]. For

example, bio-based PE, PP, PET, and poly(trimethylene terephthalate) (PTT) can be fully

or partially manufactured from bio-based feedstock, but are not biodegradable [34].

Furthermore, some petroleum based polymers, such as poly(ε-caprolactone) (PCL),

polybutylene adipate terephthalate (PBAT), and poly(butylene succinate) (PBS), are

biodegradable [36]. Sometimes, bio-based but non-biodegradable polymers and

petroleum-based but biodegradable polymers are collectively (and confusingly) referred

to as ‘biopolymer’ or ‘bioplastic’ (Figure 2) [36].

Bio-based plastics may, though not always, degrade faster, while degradation rates

depend on the environmental conditions [37]. For example, one of the most common bio-

based plastics, polylactic acid (PLA)-based plastics, are biodegradable in soils much

faster than conventional plastics, but their half-lives are similar to that of petroleum-

based polyethylene in the marine environment [5, 38]. Nonetheless, the concerns around

the dependence on fossil fuels and persistence of plastics in the environment propelled

the demand for bio-based and biodegradable plastics over the last few decades, reaching

3.8Mt, or about 1 % of the petrochemical polymers, in 2019 [39].

Waste management options of bio-based plastics differ from those of petrochemical

plastics and often cannot be recycled alongside each other. However, bioplastics can be

7

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

composted alongside conventional waste streams, such as landfills, incineration,

recycling, and anaerobic digestion [37]. Some studies suggest that anaerobic digestion is

the preferred degradation method, while others favor incineration [40]. Studies have

pointed out that clear standardization of labeling and sorting systems is needed to ensure

optimal end of life treatment of biodegrade plastics, which affect LCA results [41].

While bio-based plastics can be recycled along with conventional wastes, separating bio-

based plastics from conventional plastic waste is a better option; it can improve the

composting rate of biodegradable waste and the energy recovery rate for non-recyclable

bioplastics [42]. Although fossil fuel-based plastics currently have a price advantage over

renewable ones, accounting for the external costs and future optimization is expected to

bring the price of fossil fuel-based polymers 44 % higher than those of bio-based

polymers [34]. However, a direct comparison of environmental impacts between fossil

fuel-based and biomass-based polymers based on the literature is still challenging due to

the underlying differences among LCA studies. End of life scenarios are, for example,

modeled differently in almost every LCA study, making the environmental impacts from

waste streams difficult to compare [37]. A study has shown that bioplastic production for

replacement of petrochemical plastics can be an effective way of reducing end of life

emissions, with mechanical recycling being the optimal method for energy savings [43].

Another study also showed that the use of biomass as a feedstock for plastics can reduce

life-cycle GHG emissions from plastics [9].

Fig. 2. Common types of bioplastics and their position in biodegradability and

feedstock type spectra [44].

The majority of LCAs on biopolymers (e.g., PLA, PHA, and starch-based polymers)

focused primarily on their GHG emissions. The results demonstrated several outcomes

examining the use and potential reductions of plastics’ environmental impacts. Ref. [45]

8

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

and Ref. [44] show that using these materials may reduce climate impacts, but may result

in other environmental tradeoffs. According to Ref. [35], the process efficiency needs to

be further improved to optimize the climate benefits, though such improvement might

have taken place since the publication of study. A more recent review by Ref. [46] shows

that the shift to biopolymers can potentially reduce 241 to 316 million tonne CO

2

e GHG

emissions. A similar review demonstrates that many LCA studies on PHA show that

energy usage comparing bio-based and fossil-fuel based plastics are comparable, and

while climate change impact is typically lower for bioplastics, they often perform worse

in other impact categories [47]. In addition to GHG emissions, Ref. [33] and Ref. [48]

show that bio-based feedstocks, especially large-scale agricultural products, are usually

dependent on fossil-derived pesticides and fertilizers, which create higher impacts in

eutrophication and acidification.

In addition to improving process efficiencies, Ref. [35] points out that using energy- and

chemical-intensive crops is associated with considerable environmental impacts. Ref.

[48] demonstrate that for certain types of feedstocks, there will be a significant amount of

energy consumption during the process of converting agricultural products into plastics

materials, potentially creating a higher global warming impact. Ref. [48] and Ref. [49]

show that land-use change is also an important factor when determining the

environmental impacts of biobased plastics, and it depends on the geographical location.

According to Ref. [50], land use change and excessive harvesting of biomass cause the

release of soil organic carbon to the atmosphere and decreases soil’s ability to sequester

organic carbon. Extensive land use for bio-based plastics production will make it a

competitor with agricultural production, threatening the food value chain. From a study

by Ref. [51], it is estimated that a complete replacement of conventional plastics with

bio-based one would consume between 30 and 219 million hectares of additional lands,

and around 307 to 1652 billion m

3

of water per year.

Overall, the literature generally warns that large-scale production of bio-based plastics

may potentially create higher environmental impacts through the emissions from land use

and land management. Therefore, it would be crucial to take into account land-based

emissions when assessing the life-cycle impacts of biomass feedstock [33, 52].

2.3.3. Captured CO2-based Plastics

As compared to petroleum-based plastics that took off in the mid-20th century, CO

2

capture and utilization for plastics is still an emerging subject, as a majority of the

research has occurred in the 21st century [32]. The overall process of separating,

capturing, and using CO

2

for the creation of polymers may be done in several ways, and

companies are driving innovative processes for each method. Among the most active

companies specifically making captured CO

2

-based plastics are Covestro, Econic

Technologies, and Novomer [32]. While there are these companies making CO

2

-based

plastics, the processes are relatively new and CO

2

-based plastics are still developing on a

commercial scale [53].

Among the active companies making CO

2

-based plastics, most of the information is

contained outside of peer-reviewed literature. Each of these companies use different

proprietary catalysts to convert CO

2

into polymers. As most of the information is coming

9

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

from news outlets or from the companies themselves, it is unclear the full environmental

impacts from CO

2

-based plastics. Most emphasis on company websites are placed on

CO

2

reduction rather than other impact indicators [54, 55]. Given the nascency of the

technologies behind CO

2

-based plastics, peer reviewed literature that compares the life-

cycle environmental impacts of CO

2

-based plastics against petroleum-based or biomass-

based plastics has yet to be developed.

2.4. LCAs on Plastic Materials and Products

In this section, we reviewed 53 studies from 6 different market segments, including

packaging, agriculture, building and construction, automotive, consumer goods, and

electronics as well as the plastics industry. These industries have products of different

lifetimes, and therefore will have different scopes of impacts associated with them.

Product categories include but are not limited to bags, straws, cutlery, mulch films,

printers, and nappies. Different types of plastics and alternative materials considered

include PET, PP, and PVC. Also, some studies that specifically focus on different plastic

types are included in the review. The major takeaways are summarized by the market

sector as follows.

2.4.1. Packaging

The packaging sector utilizes the biggest portion of primary plastics produced. In 2015,

42 % of primary non-fiber plastics produced were used by the packaging industry [2].

Also, the product life-times of packaging products are very short, mostly less than a year,

making the contribution of packaging in the near-term plastics waste generation even

greater; globally, packaging accounted for 54 % of non-fiber plastic waste in 2015 [2].

Plastics are used for many applications in the packaging industry such as food containers,

bottles, bags, and cutlery. LCA studies on packaging often compare various plastics and

non-plastics materials such as HDPE, PET, PP, PS, PLA, PE, cotton, paper [49, 56-58].

These studies show that the weight of the material, use pattern, and waste management

are critical factors when determining environmental impacts [49, 57, 58].

One of the most common uses of plastics is shopping bags. Ref. [58] assess the life-cycle

impacts of 7 shopping bags and reported that use pattern, material type and weight were

the key determinants of their environmental impacts and being more preferable depends

on the environmental impact indicator that is being considered. The research here and in

other studies shows that a single-use paper bag has higher environmental impact in all

categories except eutrophication when compared to single-use plastic bags due to the

weight and paper production processes [58, 59]. In the study, paper bags are assumed to

weigh 47 g whereas the alternative single-use products made of HDPE weigh 6-8 g [56,

58]. UNEP’s report compares the two studies from Finland and Hong Kong, China and

India [60, 61]. The report states that paper bags seem to perform better in the Finnish

study mostly due to the Finnish paper production using integrated pulp and paper mills

whereas Muthu et al.’s study states a high dependence on fossil fuels in the paper

production process [60, 61]. The studies tend to show better life cycle emissions results

depending on the efficiency of the production processes.

10

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

The impact is doubled when the weight of the material used for a bag is doubled, and if a

bag is used twice, the impact is the half of a single-use bag [56]. This makes the

assumptions around the use pattern very relevant in the analysis. For example, it was

found that if a reusable polypropylene bag is used 52 times instead of 104 as assumed,

then its impact is higher than all the other single-use bags except the paper bag [57, 58].

UNEP reviewed the comparative LCAs on shopping bags covering a wide global range

including Europe, USA, and Asia [56]. The report concluded that the waste management

practices are important in determining the environmental impact and different waste

management practices are being applied across geographies [56, 60]. This becomes

important when comparing paper bags to plastic bags. Landfilled paper bags result in

methane emissions, which have higher global warming potential, whereas plastic bags are

relatively inert when landfilled [56, 60]. However, when incinerated, CO

2

emissions from

biogenic carbon in paper bags are carbon-neutral since biomass captures CO

2

by

photosynthesis while growing, whereas incinerating petroleum-based plastic bags

generate net emissions of CO

2

[56, 62]. Composting biodegradable bags decreases the

environmental impacts compared to conventional plastics, however, the availability of

composting facilities is highly dependent on the region [63].

Another common use of plastics in packaging is bottles, for which PET is the main

material in use. UNEP reviewed 7 LCA studies on single-use plastic bottles and

alternatives [64]. The alternatives suggested include single-use and reusable glass bottles,

single-use aluminum cans, single-use carton laminated packaging systems, reusable steel,

and aluminum bottles [64]. Production technology and end-of-life management practices,

which vary widely across geographies, were found as the key factors that determine the

LCA results [64]. Similar to plastic bags, bottle alternatives behave differently in

different impact categories. For example, compared to PET bottles, PLA bottles have

lower global warming potential, fossil energy use, and human toxicity, but PET bottles

have lower impact in acidification and eutrophication categories [64, 65]. Glass bottles

would have to be 3 times lighter than they are now to have a lower footprint than PET

ones [66]. End of life treatment of plastic bottles has also been studied: while even

though the majority of PET bottles are discarded, a study in China examined the

production of blankets made entirely from recycled plastic bottles where impacts

stemmed mainly from additional energy inputs resulting in global warming and fossil fuel

depletion [67]. Ref. [2] analyze the potential impact of China’s ban on the import of

plastic wastes, of which the dominant category was PET. The study shows that in the

absence of about 2 million metric tons of recyclable PET imported prior to the ban, China

is likely to use virgin coal as a substitute to produce PET fiber, increasing the life-cycle

environmental impacts for all categories considered [2].

Another use of plastics in packaging is take-away food containers. UNEP reviewed 6

LCA studies on take-away food packaging and alternatives including materials such as

fossil and biobased plastics, aluminum, paper, cardboard, wood and glass [68]. Chemical

contamination becomes an important factor for the LCA of food containers because it

deteriorates the recyclability of the material [68]. Ref. [69] suggest that compostable

tableware can be a better alternative since they can be sent to a composting facility

together with the food waste and the analysis show that compostable tableware perform

better in 7 out of 15 categories including climate change, when compared to traditional

11

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

fossil based plastic tableware [69]. Cutlery in take-away food containers is disposed of

and incinerated often without energy recovery. Shifting to different compostable

materials could result in a tenfold reduction in energy consumption [70]. Given the

preference for single-use containers for take-away food, the UNEP report recommended

that the consumer behavior and functional differences between take-away food packaging

should be taken into consideration when assessing different alternatives [68]. Also, Some

studies point out that the ability for food packaging to prevent food waste, which is often

ignored in food packaging LCA studies, is an important consideration in LCA, because

food wastes often embody higher environmental impacts than packaging itself [44]. Most

of the time, food waste has greater environmental impact than the packaging itself [68].

The weight of the material, production technology, resource use, geographical context,

and end-of-life management are crucial factors for deciding the environmental impacts of

food containers [40, 68].

The literature on plastics LCA applied to packaging generally agrees that plastics should

be lighter and use more reusable alternatives [57]. However, there are some

disagreements and inconsistencies on the impacts of single-use packaging products when

compared to plastics [11, 12, 49, 57, 58]. Overall, packaging is often not the major

contributor to a product’s life cycle impacts, and the weight of the material, resource use,

geography, process efficiency, and waste management determine the significance of its

contribution [68]. Functional use of each packaging should be defined clearly, and a

systems approach should be taken to find the best solution for each use.

2.4.2. Agriculture

Plastics are used in greenhouses, mulching, irrigation systems, crop transportation, and

many other applications in the agriculture industry [1]. We have reviewed 6 LCA studies

on agriculture which focus primarily on fossil fuel consumption, acidification, and

eutrophication. According to Plastics Europe, agriculture made up 3.4 % of the total

plastics demand in Europe in 2018 [71]. While the percentage of agriculture seems to be

low, agricultural plastics are difficult to collect from open fields and plastics can be

transported to the open waters along with other materials [71]. Chemicals like pesticides

adhere to the plastic surfaces and microplastics can carry pesticides into nearby water

bodies [72]. Biodegradation of these microplastics accelerates the release of associated

organic contaminants, many of whose effects we do not yet understand (Figure 3). The

release of plastics will in turn affect plant health and transfer to human toxicity effects.

12

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

Fig. 3. Implications of microbial habitation and biofilm formation on microplastics

[73].

Mulch film is responsible for the largest portion of agricultural plastics use (41 %)

followed by greenhouses and tunnels [74-76]. Mechanical recycling is challenging for

mulch films because they are highly contaminated with soil, stones, and biological waste.

The alternative to mechanical recycling of mulch film is the use of biodegradable

materials. These alternatives are compared to non-biodegradable plastics for mulch film

to cover 1 hectare of mulched agricultural land [76]. The potential impacts are reduced by

25 % to 80 % depending on the impact categories and the end-of-life scenario [76].

Granule production was the biggest contributor to global warming and nonrenewable

energy consumption for both biodegradable film and Polyethylene (PE) film [76].

Biodegradable plastics can be a good alternative since the waste at the end of the crop

cycle is reduced to zero [76].

Plastic greenhouses are mainly located in eastern Asia and the Mediterranean Basin,

accounting for about 10 % of agricultural plastics use [74]. The environmental impact of

using plastics materials in greenhouses is dependent on factors such as its carbon

emissions during the production phase and its generation of waste during its use in

greenhouses [77]. It has been found that plastics used in greenhouses have a smaller

environmental impact than glasses used in greenhouses during the production phases of

each material [78]. Recycling of greenhouse plastics must also be considered. Mechanical

recycling of plastics is only beneficial if they are sorted properly. Therefore, the utility of

using plastic waste to substitute other materials, such as concrete, in greenhouses is non-

13

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

value adding [78]. Additionally, PVC greenhouse materials can release heavy metal

stabilizers into the environment during mechanical recycling [78].

Another LCA study has been conducted on agricultural plastic nets. Plastic nets are

oftentimes used in agricultural operations to enhance agriculture yields and nutritional

properties as well as limit exposure to insect infestation and solar radiation [79].

However, it is often impossible to measure the global volume of agricultural net

production due to a lack of data availability from agricultural and manufacturers

associations [74]. Like mulch film, biodegradable plastic nets made of poly-lactic acid

(PLA) require a lower energy demand for production and have a lower GHG emission

equivalent than non-biodegradable plastic nets made of polymer (PE) [79]. Recycling of

agricultural plastic nets seems like a sustainable disposal method as it diverts landfill

volume and removes excess plastics from the environment. However, recycling plastic

nets can trigger water and air pollution and is confined by technological limitations that

inhibit the process from being fully effective [79].

2.4.3. Building and Construction

Plastics are an important component in the building and construction sector due to their

unique properties, such as being lightweight and corrosion resistant [80]. A number of

LCA studies have been conducted to evaluate the environmental impacts of building

materials and construction processes. We have examined 8 LCA studies in the sector

from the U.S., Europe, and Australia.

One of the most common uses of plastics in construction materials is fiber reinforced

plastics (FRP). FRP is a composite material with a polymer matrix blended with fibers,

such as carbon and glass [81]. FRP has the advantages of high durability and high

resistance under extreme environmental conditions, making it superior compared to

construction materials [80]. Using FRP instead of traditional steel significantly reduces

the amount of reinforcement by 67 % due to FRP’s comparatively low weight [81]. It is

also found that FRP reinforced pavement’s environmental impact is significantly lower

than that of steel-reinforced one, since FRP reinforced material requires less maintenance

[82]. Regarding buildings and construction, a recent study indicates that the FRP

reinforced bridge produces 50 % less carbon dioxide and requires 59 % less embodied

energy than conventional steel reinforcement [83].

Polypropylene (PP) fiber is another successful application of plastics in the building

sector [84]. PP is widely used as a popular alternative to steel reinforcing mesh (SRM),

which is traditionally used to reinforce concrete to prevent cracks [85]. Detailed LCA

shows that, compared to SRM, recycled PP fiber consumes 99 % and 91 % less water and

fossil fuel, respectively [85]. Moreover, it produces 93 % less CO

2

equivalent and 97 %

less PO

4

equivalent [85].

In addition to using plastics as replacement materials for concrete, they are also used to

replace other building materials, such as those for plumbing, flooring, and insulation.

Cross-linked polyethylene (PEX) may be used for plumbing as a replacement for copper,

and consumes 42 % less CO

2

equivalent, contains 47 % less embodied energy, and has

lower environmental impacts across impact categories than the metal [86]. PVC may be

used for flooring instead of wood or linoleum (cork), but creates 2.6 times the carbon

14

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

emissions of linoleum and 9.8 times the emissions of wood flooring, and has higher

impacts on water quality and creates more waste than the other materials [87]. Extruded

polystyrene (XPS) is a rigid cellular plastic with a closed cell structure that, along with

fiberglass and corkboard, is used as an insulation material. XPS has 57 % CO

2

equivalent

more than fiberglass, and 2.8 times the CO

2

equivalent of corkboard [88]. Moreover, it

produces 50 % and 29 % more SO

2

equivalent than fiberglass and corkboard, respectively

[88].

PVC is commonly used in water and sewer pipes in buildings. Compared to other

materials used for pipes, PVC has 61 % less embodied energy than HDPE and 56 % less

embodied energy than ductile iron [89]. However, the manufacture, use, and disposal of

PVC pose significant environmental and human health hazards. It creates long-lasting

pollutants including chlorinated dioxins, chlorinated furans (polychlorinated

dibenzofurans), polychlorinated biphenyls (PCBs), hexachlorobenzene (HCB), and

octachlorostyrene (OCS). Aside from pipes, PVC is also used for wall and floor

coverings, which is linked to higher rates of exposure to health hazards such as toxic

mold growth, heavy metals, and PVC phthalate [90]. Energy consumption and GHG

emissions from PVC are lower than similar materials, but toxicity exposure is higher. It is

important to look at various environmental and human health indicators while accessing

different plastics materials. As in the case of PVC, they might be performing well in one

of the indicators but might be very harmful in another category.

Research also found that the end-of-life treatment method is an important factor when

determining life-cycle environmental impacts. For example, the production of recycled

PP fiber emits 50 %, 28 %, and 78 % less CO

2

equivalent, water, and fossil fuel

compared to virgin PP fiber, respectively [85]. In the building and construction sector,

using recycled plastics could be a feasible and promising solution without compromising

the structural properties.

2.4.4. Automotive

Polymers and composite materials are often used in the automotive sector as a

replacement for metals [91]. One main driver is the more stringent fuel efficiency

standard, such as the Corporate Average Fuel Economy (CAFE) standard. These fuel

efficiency standards require vehicles to be more fuel efficient; weight reduction is one of

the most cost-effective approaches. Reducing automobile weight is a key method in

improving fuel economy and energy efficiency of automobiles. Compared to using metals

such as steel, using fiber reinforced plastics offers weight reduction potential in the range

of 50 % to 60 % [92]. In a review of 33 LCA studies, all studies indicate that using

aluminum, glass-fiber reinforced plastic, and high strength steel to replace conventional

steel reduces the vehicle’s GHG emissions [93]. Due to the high flexibility of options

given by the variety of materials present, these material changes will be able to reduce

life cycle emissions. Furthermore, studies have examined lightweighting specific

automotive parts through the addition of glass-fiber reinforced polymers (GFRPs). GFRP

products consistently perform better than steel alternatives in the global warming

potential, energy demand, and acidification potential categories [94].

15

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

In addition to making cars weigh less, plastics have great design flexibility [95]. They can

be molded to tight tolerances and complex shapes, with lower tooling costs than most

metal components [95]. We found 7 LCA studies mostly from Europe focusing on

plastics in the automotive sector, of which 2 focus on carbon-reinforced plastics, while

others examine plastics car parts, residue, and alternative feedstocks. Environmental

impact categories varied, but the majority included energy consumption, global warming

potential, acidification, and human toxicity.

Plastics have been widely applied in automobiles and one example is carbon fiber

reinforced polymer (CFRP). CFRP are composite materials that use carbon fiber to

strengthen the materials, while polymer enhances the cohesiveness [96]. It is estimated

that, for a passenger vehicle, applying CFRP indicates a vehicle life cycle energy savings

potential of 17 % to 25 % with assumed weight savings potential of 65 % to 70 % [97]. A

similar study compares lightweight solutions including recycled magnesium and

conventional steel to other options in a cradle-to-exit gate stage modality. Out of those

solutions, CFRP has the best performance [98]. However, concerns about high energy

intensity and cost may become major barriers to large-scale CFRP production and

application. It is estimated that the energy intensity of carbon fiber production is 14 times

higher than conventional steel production [92]. CFRP and steel energy consumption is

found to be comparable when considered from the perspective of input data variability

due to numerous sources used [92]. The high energy content of carbon fibers results in

higher energy recovery in recycling, and a lighter weight in lower use phase energy

consumption. Other common reinforcement materials include glass fiber, clay, and

natural fiber, which is further discussed in section 2.5.3 [7, 99].

Similar to other sectors, end-of-life treatment is also an important consideration for

plastics usage in the automotive industry [100]. In 2015, the European Union’s End-of-

Life Vehicle (ELV) Directive set specific recycling targets for vehicles and components

[100]. It requires that since January 2015, for all end-of-life vehicles, a minimum of 95 %

of vehicle weight needs to be recycled [100]. In Europe, the recycling rate of automobiles

is high because the metallic fraction (usually 75 % of the vehicle weight) has been

recycled [101, 102]. The remaining 25 % of material consists of plastics, fibers, and

glass, which is also called automotive shredder residue (ASR). Therefore, the use of

plastics in ASR is a hurdle in achieving a higher recycling rate of the vehicles.

Several studies evaluate the environmental impacts of ASR treatment. Ref. [102]

evaluated different end-of-life treatment methods, including landfill, incineration,

mechanical recycling, and chemical recycling. The results indicate that small-scale

recycling plants, modeling with mechanical recycling and chemical recycling options,

achieved the lowest impacts due to energy and material recovery [102].

2.4.5. Consumer Goods

Plastics are widely used in many consumer products such as toothbrushes, wipes,

nappies, feminine products, masks and other personal care products. We found eight

studies examining plastics in consumer goods, two of which were analyses of already-

published studies. Most of these studies analyzed plastics materials in Europe, however,

other studies were held in the United States and Brazil. Environmental impact categories

16

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

varied from study to study, but common ones include global warming potential, ozone

depletion, and human toxicity.

Johnson & Johnson analyzes different handle materials for its toothbrushes to reduce

environmental waste and integrate environmental issues in its product design and

development [103]. The results show that incorporating pre-consumption plastics waste

into toothbrushes reduces both production costs and environmental impacts by 44 %

[103].

A study from the UK comparing single-use nappies (diapers) to reusable ones concludes

that there is ultimately no better product [104]. The drivers of environmental impacts are

different in single-use and reusable nappies [104]. Single-use nappy manufacturers can

reduce nappy’ weight and improve the manufacturing process, whereas reusable nappy

users can reduce the energy consumption for washing and drying to lower their

environmental impacts [104]. Use patterns and end-of-life disposal are also important

factors while determining environmental impact of reusable nappies [104]. Biobased

nappies demonstrate potential reductions in environmental impact if they are composted

at the end-of-life [104].

When comparing different feminine products, reusable menstrual cups perform better

than single-use pads and tampons [105]. Single-use tampons have a lower environmental

impact than single-use pads, especially if there is no applicator [105]. Additionally,

reusable menstrual cups produce less than 10 % of the costs of disposable products [105].

Again, the life-cycle stage that has the biggest contribution changes depending on the

product. The use-phase is an important stage for the menstrual cups, that depends on

water use and washing frequency [105].

Today, personal protective equipment such as masks are widely used, primarily due to

the global pandemic. There are various single-use and reusable masks on the market.

According to a study, reusable masks have a lower environmental impact than disposable

masks [106]. The most important contributors to the impact change depends on the

reusability of the product [106]. Material production, packaging, and end-of-life

management are significantly impactful stages for the disposable masks, while the use-

phase (washing and sterilization) are the most important stages for the reusable masks

[106].

UNEP’s report on single-use plastics products emphasizes the importance of

geographical and cultural context in the analysis [105]. Geographical location affects

resource availability and use, energy mix, and production technology [105]. Cultural

context affects the adoption of alternative materials and user behavior [105]. Both

cultural and geographical factors affect recycling rates and end-of-life management

practices [105]. While a comparison of many LCA studies indicated that recycling is on

average the preferred option if it could replace at least 70 % to 80 % of virgin plastics,

this depends on the performance of recycled plastics as well as the efficiency of

mechanical recycling and energy recovery that results [107]. The majority of LCA

studies conclude that single polymer plastics recycling with minimal contamination

replace virgin plastics at a ratio close to 1:1, and recycling is generally the preferred

treatment option [108]. However, these conditions do not always occur. As demonstrated

17

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

in several studies, recycling performance is optimized when pretreatment is adapted to

the recycling technology, which may reduce emissions from the most demanded plastics

by up to 73 % [109]. However, post-treatment of plastic solid waste from goods is also

important with reviews showing that pyrolysis is often the preferred advanced waste

treatment technique with advantages from bio-oil and biochar production [40].

Each study had varying results, however, it was found that recycled and reusable

materials found in consumer goods generally have a lower environmental impact than

virgin plastics materials.

2.4.6. Electronics

The market for consumer electronics is rapidly growing, and historically environmental

impacts have not been considered in the product design and development processes.

Fossil-based plastics are widely used in electronics. Additives in the composition make it

difficult to recycle and reuse; therefore, the recycling efficiency is low [110].

Two studies that are reviewed in this report focus on laptops and printer panels as case

studies and evaluate the impacts of the use of fossil-based plastics and alternative

materials, including bio-based materials, aluminum, and bamboo [110, 111]. Many

electronics products are still lacking in life cycle assessment studies and do not have

many publicly facing studies available. The laptop case study found that in order for

metals to be a better option than plastics, the recycled content of the product should be

above a certain percentage depending on the metal, thus replacing the primary metal

production [110]. To be able to understand the impacts of bio-based materials, there

needs to be more research on end-of-life of bio-based materials. In general, increasing the

post-consumer recycled content in consumer electronics will result in tangible reductions

in environmental impacts [110].

Another study shows that additives in printer panels are the biggest contributors to

cradle-to-gate GHG emissions of a printer’s GHG emissions (up to 40 %) [111]. For both

flame retardant and non-flame retardant panels, two alternative biobased plastics are

suggested [111]. For flame retardant panels, biobased material provides similar

environmental and economic performance, whereas, for non-flame retardant panels, the

environmental performance is improved with the biobased alternative [111].

2.5. LCAs on Plastics Additives

Additives in the plastics industry are chemical compounds that are added to basic

polymers to enhance the performance, functionality, and aging properties of plastics

products [7]. Generally, there are four main categories of additives: (1) functional

additives, (2) colorants, (3) fillers, and (4) reinforcements [7]. Specifically, functional

additives include plasticisers, flame retardants, stabilisers, slip agents, lubricants, curing

agents, blowing agents, and biocides [7]. Under each of these categories, there are many

potential available chemical substances, ranging from a simple substance such as zinc

oxide (an inorganic pigment) to complicated organic substances such as bis (2-

ethylhexyl)phthalate (DEHP, a common plasticiser) [7]. Due to the heterogeneity of these

substances, the amount and quality of the studies vary significantly across the categories.

Overall, additives are often omitted from plastics LCA studies [37].

18

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

There are two main types of LCAs for these additives. The first one is the cradle-to-gate

LCA for the substances themselves. There are more studies of this type, considering there

are existing LCA tools and databases for chemical substances. Some examples include

the Chemical Life Cycle Collaborative (CLiCC) and the Environmental Assessment Tool

for Organic Synthesis (EATOS) [112, 113]. If the additives do not affect the life-cycle

characteristics of the products significantly (e.g., the colorants which only change the

color of the products), this type of study can be simply integrated into the LCA of the

plastics products. However, for additives such as stabilisers, which would significantly

increase the life-time of the product, comprehensive LCAs for the product with and

without such additives will be necessary to understand their environmental impacts. The

second type of the LCA, which is the cradle-to-grave LCA for the plastics products with

the consideration of the additives, would be a better fit to understand the impact. There

are fewer studies of this type in the existing literature, and most of them focus on specific

industries, probably due to the initiatives in such industries for sustainability. To develop

this type of comprehensive analysis, it is necessary to predict how various additives

would affect the service life-span and degradation rate of a plastics product.

In the following sections, 12 LCA-related articles are reviewed regarding additives in

plastics production. If an additive category is not reviewed, it means we cannot identify a

significant amount of LCA studies focusing on its applications. However, it is still

possible to find LCAs of the substances in the category in databases like CLiCC or

EATOS.

2.5.1. Functional Additives

2.5.1.1.Plasticizers

Plasticisers are small organic molecules, which are used to improve the flexibility and

processability of polymers [114]. The impacts of plasticisers on human health and the

environment have been widely studied, and there are existing tools to help evaluate the

risks of certain plasticiser substances [114, 115]. However, there are only a few studies

that use LCA to analyze the environmental impacts of plasticisers, and these studies are

usually cradle-to-gate LCAs for specific plasticiser substances. The European Council for

Plasticisers and Intermediates (ECPI) applies cradle-to-gate LCA on the production of di-

isononyl phthalate (DINP) [116]. Since this study only focuses on DINP instead of

evaluating a range of plasticiser substances, the result cannot provide much insight.

Another study in 2013 applies cradle-to-gate LCA to DEHP, and compared its impacts

with acetyl tributyl citrate (ATBC) and diisononylcyclohexane dicarboxylate (DINCH) in

a semi-quantitative fashion (full LCAs for ATBC and DINCH are not applied) [117]. The

study concluded that DINCH has a higher cradle-to-gate impact than DEHP, but has a

lower impact when considering the use phase [117].

2.5.1.2.Flame Retardants

Flame retardants (FR) are used to inhibit, suppress, or delay the ignition in plastics [118].

Similar to other additives, FRs are usually ignored in plastics LCA studies, yet there are

still several cradle-to-grave studies focusing on the use of FRs in various products [118].

Deng and co-workers apply cradle-to-grave LCAs to two printed circuit board (PCB)

substrates--a biobased one using melamine polyphosphate (MPP) as FR and a

19

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

conventional one using tetrabromobisphenol A (TBBPA) as FR [119]. They show that

the biobased PCB has better overall environmental performance, but has a worse land-use

impact [119]. Jonkers and co-workers apply cradle-to-grave LCAs to two types of

laptops, one using brominated flame retardants (BFR) and another one using halogen-free

flame retardants (HFFR) [120]. They conclude that BFR has worse environmental

impacts compared to HFFR, which is mainly caused by the high human toxicity impact

of BFR in the end-of-life stage of the product [120].

The main function of FR is to prevent the risk of fire, which would affect the life-cycle

characteristics of the plastics products. Since conventional LCA assumes a normal

operation during the life-cycle of the product, it cannot necessarily capture the potential

environmental benefits brought by the prevention of the fire events due to the FRs. To

tackle the problem, a research group in Sweden developed a Fire-LCA model [121]. This

model is a cradle-to-grave LCA model including fire event as a potential end-of-life

scenario for the product and includes all the corresponding emissions of the fire event in

the LCA analysis [121]. In another study from the same group, they applied the Fire-LCA

model to two types of TV enclosures--one with FR and one without FR and concluded

that the TV enclosure without FR has significantly higher life-cycle emissions due the

emissions from the potential fire event [122].

2.5.2. Colorants

During our review, we could not find LCA studies focusing on the application of

colorants in the plastics industry. However, unlike other additives which are usually

ignored in existing LCAs for plastics products, colorants are sometimes included. For

example, both USEEIO and CEDA include synthetic dyes and pigments in their analyses

for plastics products [25, 26].

2.5.3. Fillers and Reinforcements

The term “functional fillers” is sometimes used to describe both fillers and reinforcement

in plastics production. The purposes of adding fillers and reinforcements into plastics

products are usually cost reduction and property (especially mechanical property)

enhancement [99]. Typical filler/reinforcement materials include talc, clay, natural fiber,

carbon fiber, and glass fiber [7, 99]. Natural fiber, such as wood, cellulose, cotton, and

flax, are gaining more attention in current studies due to their “green” characteristics

[123]. Compared to other additive categories, there are relatively abundant studies on this

topic.

The first type of study compares plastics with fillers to virgin plastics using LCA. Vidal

and co-workers applied LCAs to virgin plastics and recycled thermoplastic with rice

husks and cotton linters; they concluded reduced environmental impacts for the latter

[124]. Wotzel and co-workers apply LCAs to car side panels made of acrylonitrile

butadiene styrene (ABS) and hemp fiber composite and discover that the latter has the

better environmental performance [125].

The second type of study focuses on comparing plastics with different types of fillers

using LCA. Corbiere-Nicollier and co-workers compare the environmental impacts of

plastic transport pallets made of PP reinforced by glass fiber and PP reinforced by China

20

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

reed fiber [126]. They show that China reed fiber reinforced PP has lower environmental

impacts [126]. Korol and co-workers studied the environmental impacts of plastic pallets

made of PP reinforced by glass fiber and three different natural fibers (cotton, jute, and

kenaf) [127]. They found better environmental performances for jute and kenaf

reinforced PP compared to glass fiber reinforced PP. However, cotton reinforced PP has

the worst environmental performance due to its cultivation process with significant

environmental impacts [127]. Luz and co-workers researched the environmental impacts

of sugarcane bagasse reinforced PP and talc reinforced PP and concluded a better

environmental performance for the former [128]. It is worth mentioning that most of

these studies focus on products in the automobile industry, probably due its initiative in

improving product sustainability.

2.6. Overall Trend Summary

In general, literature agrees that use pattern assumptions are critical when comparing

single-use and multi-use products [11, 12, 64, 105, 129]. Multi-use products might not

perform better if they are not used sufficiently many times.

98

The production phase of

multi-use products might have more environmental impacts than the single-use products,

since they might require more inputs to make them more durable.

Various papers showed that waste generated from plastics can cause a variety of

environmental impacts, and end-of-treatment methods greatly affect LCA results.

Compared to landfilling, recycling has lower environmental impacts, including GHG

emissions, water consumption, and fossil fuel consumption [85, 102, 130]. But the cost of

pre-sorting and collecting waste makes it hard to improve the recycling rates globally

[131]. In addition, regional waste management policy is an important determining factor.

For example, the EU requires that plastics packaging is either reusable or recycled in a

cost-effective way by 2030, which incentivizes plastics recycling in the EU market.

Regarding the LCA for recycling itself, papers showed that allocation of the

environmental benefits of recycling lacks a consistent approach across the industry, and

various industrial guidelines provide different suggestions [132]. This obscurity would

potentially lead to double counting of credits across the whole economy [132].

Many papers show that factors that are being considered in the assessments depend on

geographical and/or cultural context [56, 68]. These factors include resource availability

and use, feedstock mix (virgin materials, fillers, and recycled materials), energy mix,

adoption of new materials and manufacturing technologies, user behavior, recycling

rates, and end-of-life management practices [56, 68].

Challenges and Gaps in Plastics LCA

There are several challenges in understanding the life-cycle environmental impacts of

plastics that have been identified through our review.

First, there is a lack of reliable, up-to-date, high-quality, and regionalized data on plastics.

The reviewed LCA databases are highly concentrated on the EU and North America

markets. In the seven reviewed LCA databases, USEEIO, NREL, and CEDA are based in

the United States. PlasticsEurope only covered European countries. Gabi covers both US

21

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

and EU countries and CM.Chemicals has broader regional distribution. Ecoinvent has

limited data for the Asian market, while Asia has emerged as the major contributor to

global plastics production with approximately 51 % of the world’s plastics produced in

Asia in 2019 [1]. Region-specific emission factors are needed to accurately represent the

background energy mix scenarios and end-of-life treatment options. Some of the recent

datasets such as CM.Chemicals, however, started to address region- and supplier-specific

life-cycle environmental impacts.

Second, existing LCA studies do not address the environmental, ecological and human

health impacts of microplastics and the degradation byproducts from plastics.

Microplastics are abundant in marine and freshwater environments [133]. However, the

health impacts of microplastics are still not well understood [38, 133]. Research shows

that microplastics, due to their composition and relatively large surface area, might

transport contaminants up the food chain which can accumulate in the tissues of the

organisms [134]. The research in this space of understanding plastic degradation is only

emerging, and there are several pathways of degradation that must be considered (Figure

5). Weathering proceeds along multiple synergistic pathways that would be difficult to

model in an LCA study due to the variety of pollution-caused damages that occur,

including those to the carbon and nutrient cycles, habitat changes, changes to ecotoxicity,

and societal impacts [38].

Fig. 4. Weathering processes of poorly reversible plastic pollution [38].

Third, additives are essential ingredients for plastics products, but additives are poorly

covered in LCA studies. We reviewed twelve articles utilizing LCA to analyze the

environmental impacts of additives in the plastics industry--one for plasticizers, five for

flame retardants, and six for fillers and reinforcements (with special focus on organic

reinforcement materials in the automobile industry). Other functional additives such as

stabilizers, slip agents, and lubricants are usually missing in the existing literature [37].

Integrating additives into LCA for plastics products is challenging for several reasons.

There are many potential substances, and no generalized LCA can cover them all. Also,

22

This publication is available free of charge from: https://doi.org/10.6028/NIST.GCR.22-032

some additives will alter the characteristics of the product (e.g., prolonged lifetime,

reduced fire risk), and such characteristics need to be embedded in the cradle-to-grave

LCA for accurate results. The impact of plastics additives also depends on the end of life

(EOL) treatment for the product, which would decide the final destination of the additives