Source Approval

Request

NSN: 1640-01-281-5201 P/N: XXXXX-X

Cage Code: XXXXX

TABLE OF CONTENTS

Appendix A………………… Cover Letter…………………………………........... 3

Appendix A.i………..Quality Documents………………………………… 6

Appendix A.ii……….Company Brochure………………………………… 8

Appendix B………………… Qualification Part Drawings……………………….. 14

Appendix C………………… Qualification Part Manufacturing Plan…………….. 20

Appendix D………………… Master Tooling Certification……………………..... 22

Appendix E………………… Data Certification………………………………….. 23

Appendix F………………… Qualification Part Subcontractor List……………… 24

Appendix G………………… Qualification Part Shipping Docs………………….. N/A*

Appendix H………………… Similar Part Drawings………………………………N/A*

Appendix I…..…………….. Similar Part Shipping Documents………………..... N/A*

Appendix J………………… Comparative Analysis……………………………… N/A*

Appendix K………………… Similar Part Manufacturing Plan……..……………. N/A*

Appendix L………………… Similar Part Subcontractor List..……..……………. N/A*

Appendix M……………….. Test Plans……………………………..……………. 25

Appendix N………………… Licensee Agreement…………...……..……………. 26

Appendix O………………… Summarization, Quality, Deficiency….…………….N/A*

Appendix P………………… Inspection Method Sheets……...……..……………. 27

Appendix Q………………… Engine Parts Special Requirements…..……………. 29

Appendix R………………… Technical Briefing……………..……..……………. 29

Appendix S………………… Sample Part…………………………..……………. 29

Appendix T………………… Value Added…………………..……..……………. 29

* These sections are not applicable to a Category III (New Manufacturer) SAR package

Appendix A - Cover Letter

November xx, xxxx

SUBJECT: Source approval request for NSN 1640-01-281-5201, P/N:

To Whom It May Concern:

Please consider this data package to be a category III source approval request by Company X

Incorporated to become an approved source for NSN 1640-01-281-5201. All required data as

specified in the source approval guide as outlined in the table of contents has been included.

Part:

NSN: 1640-01-281-5201

CAGE: XXXXX Part Number: XXXXX-X

Nomenclature: WIRE ROPE ASSEMBLY,SINGLE LEG

Weapon System: LVS POWER UNIT MK48 AND TRAILER FAMILY

Contact Information:

Company X Inc.

CAGE:

Address

Phone: Fax:

E-mail:

Quality Program:

System used: ISO 9001:2008

Quality Manual: Please see Appendix A.i

Company X Company Information:

A company brochure has been included which outlines Company X capabilities. Please see

attached information in Appendix A.ii

Company X Incorporated requests that we be classified as a manufacturer for source approval

requests submitted to any of the engineering service activities for review. We are not a

distributor but an engineering firm which acts as a system integrator for government contracts.

Company X Inc, as the prime contractor, is responsible for technical and financial liabilities on

all contracts we supply.

Systems Integration:

Most repair parts are not simply a piece of metal machined into the final product. Usually there

are multiple operations at different facilities which need to be successfully completed in order to

create a specification compliant part. Company X Inc contracts and manages each specialty

manufacturer needed to produce a part. For example Company X will subcontract the casting to

a foundry, the milling to a machine shop and the plating to a plating shop. Each individual sub-

contractor is not able to produce the complete part. Final assembly, marking and painting is also

completed at our facility for some repair parts. Only through Company X coordination including

on-site audits of special production requirements, i.e. QE-STD-1 for CSI parts, will a complete

specification compliant part be produced by these small businesses.

Engineering:

The upfront engineering of each part under contract with the US Government takes place at

Company X. This can include but is not limited to: developing a manufacturing plan, making the

CAD model used to write the CNC code, updating drawings, creating new drawings and

designing testing equipment for contractor first article and production testing.

Packaging, Measurement, Testing, Assembly, Marking and Cleaning\Lubricating:

Company X Inc is approved for all forms of MILSPEC packaging up to, but not including, a

clean room. All parts supplied to the military by Company X are packaged in house including

RFID tags. Final marking, painting, assembly and lubrication of parts are also done in house on

certain jobs.

Quality Assurance/Inspection:

Company X Inc is ISO 9000:2008 certified to “Manufacture and repair of parts to the military.”

(A copy of this certification has been attached) We are compliant to ISO 10012:2003 for

inspection. Company X Inc has a resident DCMA Quality Assurance Representative (QAR) who

conducts all contractual source inspections at Company X’ facility. Additionally, we are certified

as the Prime to deliver Nuclear, Level 1 and Sub-Safe parts for the US Navy. The DCMA

Nuclear QAR conducts his inspection at our facility as well.

Based on the fact that Company X is accountable for the manufacturing, quality, and

performance of parts delivered to the US government, we request to be classified as the

manufacturer for SAR process considerations.

Background Information:

Company X Inc is a key supplier to Lockheed Martin Corporation (LMC) on their Fleet

Automotive Support Initiative-Global (FASI-G) contract (contract number XXXXXXX out of

DSCC). Lockheed Martin has come to Company X to reverse engineer and provide alternate

sources for several items where the sole source is forcing the pricing above where LMC can

effectively sustain supporting them.

Company X has successfully reverse engineered and supplied many automotive parts to TACOM

and the Marine Corp over the past 5 years (often through DLA). We are very familiar with the

requirements of military vehicles and the challenges associated with them. We are experienced at

supplying specification compliant repair parts have been on contract directly with DLA for 3 of

the past 4 years to provide reverse engineering and breakout services to DSCC and DSCR.

LMC provided Company X with sample assets from their inventory for reverse engineering.

Company X reviewed the available unlimited rights data and technical manuals. We reviewed

how the parts fit up in their application by going to our local Army National Guard base which

has most wheeled army vehicles including the M1000, M984A1, M977 and M985. We used this

information along with parametric data and material analysis data to create a new technical data

package (located in Appendix B).

LMC will be managing this item for DSCC under their contract for up to the next 10 years and

has bought the full data rights to the drawings. As a result we have added LMC onto the

drawing as an approved source of supply. We ask that if you find this SAR package to be

acceptable you catalogue both Company X (CAGE) and Lockheed Martin (CAGE 02769) as

approved sources.

Company X engineering department is available and more than willing to discuss over the

phone, e-mail or in person any questions or concerns you may have during the review of this

SAR.

Respectfully Submitted,

Senior Engineer

Appendix A.i

Quality Documents

Attached in this appendix is Company X ISO 9001:2008 certification (3

rd

Party

Audited) for the

“Manufacture and Repair of Parts for the Military.”

The ESA has already received a copy of our quality manual with other previously submitted

SARs. Should the latest copy be required please contact Company X and we will be happy to

e-mail it.

g

l

obal

assurance

This Is to certify that

t11e

Quality

Management

System

of:

Company X

ap

p

l

i

ca

b

l

e

t

o:

Manufacture and repair of parts for the military

has been

assessed

and approved by

National Quality Assurance,

U

.S.A.,

against the provisions

of:

ISO

900

I

:2

008

For

and

on

b

ehalf

of

NQA.

USA.

Acton,MA

01720

C.rt

l

ficate

Number:

123

EACCode:

XX

First

Issued:

November

6,

2003

Val

i

d

Until

:

OCtObEr

Z

.

Z

OI

Z

Reissued: Octobor

2

,

2009

This

a

pp

rove

!

i

s

subject

to

the company

maintain

i

ng its

svstem

to the

reQuired

standud.

whk:h

will be

monitored

by

NQA, USA,an

acc

re

d

i

te

d

organization under

the

ANSI·ASQ

Natioo

a

l

Accreditation

Board

.

Appendix A.ii

Company Brochure

Included in this appendix is the company brochure for Company X Inc.

Baseline Business – DOD Repair Parts

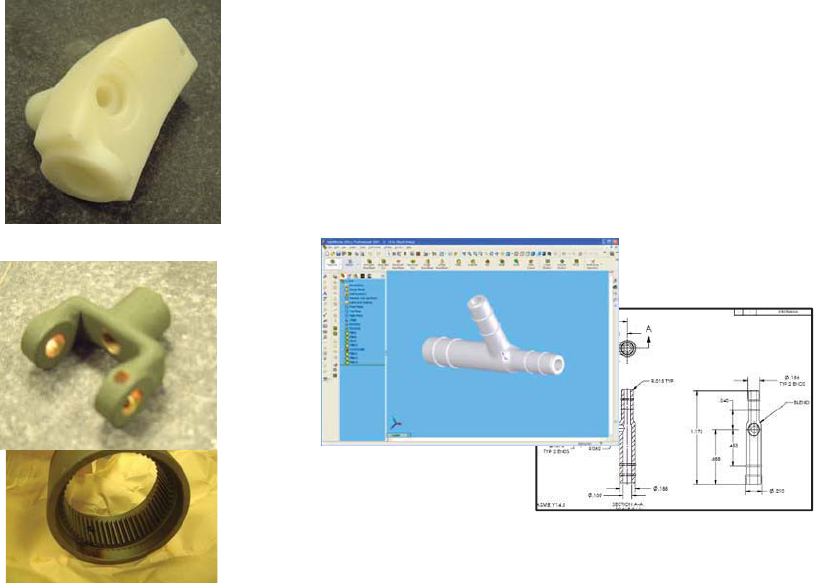

Our baseline business is focused on winning competitively awarded repair part

contracts with the Department of Defense. We concentrate on metal and plastic

parts that are machined, fabricated, or cast with low to moderate annual volumes

primarily associated with five year contracts. We take a government solicitation

and turn it into a complete commercial package so that our partners can focus on

what they do best, manufacturing parts.

Company X Supply Chain

Advantage

Bearings

Valves

DOD

Co

mp

an

y X

Fasteners

Foundries

Machining

Fabricators

….

Company X has small set of individually qualified manufacturing partners which

we use to source production of parts. All of our manufacturing partners must

adhere to strict quality requirements validated through regular on-site visits.

Company X Software Advantage

Company X has developed a complete set of in-house software

which allows us to take the government EDI transactions and filter

them to target the specific niche of each of our manufacturing

partners. We can dynamically adapt our filters to match the current

capabilities, appetite and capacity of each partner. This software

also provides complete work flow management from solicitation to

award to delivery.

Company X Engineering Advantage

A manufacturing engineer from our engineering team looks at every technical data

package, creates a manufacturing process map, and then determines which

partners are the best fit to produce it. All parts come with a “Master Record”

which provides our partners with a quick look on everything needed to

manufacture the part. Every part is assigned to a specific engineer who provides

technical support throughout the manufacturing process.

Company X Inspection and Shipping Advantage

With an on-site DCMA QAR for source inspection and a complete packaging

facility for all MILSPEC packaging up to, but not including, a clean-room,

Company X manages all aspects of a government contract\delivery order.

Engineering Technical Services

Company X is at its heart an engineering firm with many resources to provide rapid

manufacturing and logistics solutions to the US Government. Not only can we help once a

problem part has been identified but Company X has developed software which allows us to

work with the Defense Logistics Agency to help them identify potential problem parts before

they become backorders.

Obsolete Parts Solutions

Instead of using surplus for a short term solution, we evaluate state-of-the-art engineering

answers for obsolete parts and work to put in place a long term solution. Company X has a team

of manufacturing engineers dedicated to supporting problem parts. Working closely with the

Defense Logistics Agency and the In-Service Engineering Support Activities (TACOM,

AMCOM, NAVSEA, NAVAIR, WR-ALC, TINKER etc.) we develop a complete sourcing

solution. We not only reverse engineer and/or re-engineer parts but we also produce and provide

the parts to the troops in the field and the sailors at sea.

x

From Complex Submarine Parts…

o To Army Critical Suspension Components…

x

To Electro-Mechanical Assemblies…

WE DELIVER RESULTS!!

Quality and Inspection Systems

Company X is registered ISO 9001:2000 and

have been since the company’s first year.

All parts that Company X manufactures are

carefully inspected to ensure that they are 100%

specification compliant. We have a large capacity of

in-house mechanical inspection equipment and

maintain an ISO 10012 compliant inspection

system. Most government source inspections are

done in house at

Company X.

Our customers recognize our superior quality and have rewarded us:

x 2004 Gold Medal, Best Value Supplier, by the Defense Supply Center Richmond

x Class II and III Fastener Qualified Supplier by the Defense Supply Center Philadelphia

x Verified Supplier Lists for: Nuclear, Level 1 and Sub-Safe repair parts for the US Navy

x Company X maintains a 100% quality rating by DLA’s AVBS score

Appendix B

Qualification Part Drawings

Included in this appendix are the following drawings and first page of specifications required for

production:

New Proposed TDP:

CAGE Drawing Data Rights

XXXXX XXXXX-X UNLIMITED

Supporting Specifications (only first page provided):

RR-W-410

OEM Data (provided for reference):

CAGE Drawing Data Rights

45152 1307990 Rev B Government owned with unlimited rights

45152 1308000 Rev C Government owned with unlimited rights

45152 1308010-U Rev Basic Government owned with unlimited rights

See Appendix M for more data on the TDP creation and test plans

Source Approval Request

NSN 1640-01-281-5201

MOORESTOWN

NJ

ITEM

1

1

75535

S-501

8 7 6 5 4 3 2 1

APPROVED SOURCE(S) OF SUPPLY 4

CAGE PART NUMBER NAME AND ADDRESS

REVIS ONS

ZONE REV.

DESCRIPTION

DATE APPROVED

A TDP RELEASED 11/20/2009 N BIRD

9230L4000 Company X INC F

F

9230L4000

LOCKHEED MARTIN CORP

XXX MAX AFTER SWAGING

5

E

E

D

D

2

2

C

C

1 XXX

ft X ft

Notes:

1: QUALIFICATION TESTING: TEST FIRST ASSEMBLY TO FAILURE TO ENSURE TOTAL STRENGTH

EXCEEDS REQUIREMENT. REQUALIFICATION IS REQUIRED FOR ANY CHANGE IN

B

MANUFACTURING PROCESS ASSEMBLY MANUFACTURER OR CHANGE IN SUBCOMPONENT

MANUFACTURER.

2. SEIZE END OF ROPE NOT ATTACHED TO SOCKET

B

NO.

QTY. CAGE PART NUMBER DESCRIPTION MATERIAL

SOCKET

SWAGE STYLE OPEN STEEL SOCKET FOR USE WITH XXX" DIA WIRE ROPE

XXXX TON MINIMUM RATING

3: PREPARE FOR DELIVERY: WIND ONTO REEL WITH SEIZED END ON OUTSIDE OF COIL

4.

ONLY THE ITEM AS DESCRIBED ON THIS DRAWING WHEN

2 AR XXX XXXXX WIRE ROPE

X" DIA EXTRA IMPROVED PLOW STEEL WIRE ROPE MIN BREAKING

STRENGTH XXX TONS XXX SEALED ROPE IWRC CORE BRIGHT FINISH. TYPE

I

CLASS 3 CONSTRUCTION 6 PER RR-W-410

PROCURED FROM THE VENDORS LISTED HEREIN IS APPROVED.

A

5. 100% INSPECTION REQUIRED ON THIS DIMENSION. NOT

APPLICABLE TO SPELTERED SOCKET OPTION.

PROPRIETARY

AND CONFIDENTIAL

THE

INFORMATIONCONTAINED

INTHIS

DRAWING

ISTHESOLE

PROPERTY

OFLOCKHEED

MARTIN

CORPORATION.ANYREPRODUCTION

INPARTORASAWHOLEWITHOUTTHE

WRITTENPERMISSIO N

OF

LOCKHEED

MARTIN

CORPORATION

ISPROHIBITED.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

ANGLES

2

X .1 XX .03 XXX

.010

DRAWN

CHKD

APPVD

CONTRACT

11/14/2009

11/20/2009

TITLE:

Company X

INCORPORATED

A

WIRE ROPE ASSY

6.

ALTERNATE PART NUMBER (NOT SHOWN): XXX SWAGE STYLE OPEN

STEEL SOCKETFOR USE WITH X" DIA WIRE ROPE XXX TON MINIMUM RATING

1301550-U M984

NEXT ASSY USED ON

INTERPRET DRAWING PER

ASME Y14 5M - 1994

COMMENTS

SIZE

C

CAGE CODE

DWG NO.

REV

A

RR

-

W

-4

10

F

RR

-

W

-4

10

E

7

Febm

u

y

2002

FEDERAL

SPECIFICATION

WIRE ROPE

AND

S1RAND

The

G

e

n

era

l Ser

vice

s

Administration has

authorized

the

use

of this

federa

l

specificat

i

on

by

all

f

edera

l

agencie

s

.

I.

SCOPE

AND

ClASSIFIC

A

T

ION

1.1-

This

specificat

i

on

covers

wire

ropes

and wire seizin

g

sb

·

an

d

s

(see

6.1).

1bis

specificatio

n

do

e

s

not include.

all

types

,

classe

s

,

c:o

u

structious

.

and

s

ize

s

of wire

rop

e

.

and

strand

that

are commerc

ial

l

y

a

v

aila

b

l

e

,

but

it

is

intende

d

to cover

the more conunou

t)pes,

cla

s

s

e

s,

c<nLStruc

t

i

oos

,

aud

s

ize

s

that

are

s

uita

b

l

e

for

federal

go

v

ernmen

t

use..

12

Classi

fic

a

t

i

on

.

1 2.1

T\tpes.

classes

C011Struc1ions.

and siz.es.

Wire

ropes

and

\Y

i

r

e

seizing

st

ran

d

s

co'\

.

·

ered

b

y

this

specification

shall

be

of the

f

ollow

i

n

g

types,

cl,

coustn>etiou

s

.

,

and sizes

as

specified

(see 6.2

(b)).

For

ge

n

era

l

rule

s

for

s

e

l

ec

tion

ofw:ire rope an

d

s

n

·

and

,

see

6

.

3

and

the

W

i

r

e

Rope

Users

Manual.

F

or

wire

rope and strand

defillitio

a

o

nd

t

etlllS

,

s ee

6

.

4

and

the

W

ire

.

Rope

Users

Ma

n

u

a

l.

Type

I

-

Geuera

l

ptupose wire

rop

e

s

CLass

I - 6

b

y?

CLass

2 - 6 by

19

Construction

I

Construction

2

Construction

3

Construction

4

Construction

5

6

by 19

(2

operatiou.

s

)

6

by 19 Warrington

6

by 19

S

eale

6

by 19 Filler wue·

6

by 19 Warrington-Seale

that

w.1y

improve

this document

should

be

seut

to: STDZNMGT

iiil

dla

.

mil or

Defeu.se

Supp

l

y

Center

Richmond,

ATIN :

DSCR

-

VEB

,

8000

Jefferso

n

D"

i

'

s

Hi

ghway

,

Richmon

d

,

VA

23297

-56

1

6

.

AMSC

N/A

FSC40

10

.

i

.

OIM

-

.

-..-

•,

ll

i\

.,..,

,..IIIJT

Source Approval

Request

NSN

1640-01-281-5201

N

A

s

e

e

[

r5Nt

4

I

3

J

_

rb.""

130799o

r'

II

I

I

SUGGESTED SOURCEtSI OF

SUPPLY

REVISIONS

CAGE

PART NUMBER

NAME AND ADDRESS

ZONE

TR DESCRIPTION DATE APPROVED

A4

A

ADDEO NOTE

3

ECN

2620 JJG 2-27-84

75535

CROSBY GROUP

INC

ADDEO DAAE07 83 C H418

CN

71308

NJ8

5 13 88

11A8

D

D

-

c

r--

c

-

-

8

NOTE

8

I. "IDENTIF

SOURCEIS

BE CONST

OR CONTI

1

-

OF SUPPL

r--

2.

SEE

OSHK

DRAWING

TECHNICA

RATION

3.

"ONLY TH

WHrN PRO

HEREON I

CORPORAT

DUTY

A

CH

TO

THE C

SUB COMP

PRIOR NOTIFICATION TO AND APPROVAL

FROM

NEXT

ASSY

USED

ON

52[Dvi

3

0

7

9

9

o

OEMDRAWINGSINSERTED

HERE(IFAPPLICABLE)

Appendix C Qualification

Part Detailed

Manufacturing Plan

Included in this appendix is the detailed manufacturing plan(s) which identify all processes and

materials as well as which steps will be performed by subcontractors. A detailed list of

subcontractors is provided in appendix F.

Source Approval Request

NSN 1640-01-281-5201

Original

Date:

11/23/2009

P.O.:

MP

Rev:

A

MP Rev

Date:

11/23/2009

Company X Inc -

CAGE:

Subcontractor:

YYYY WIRE ROPE

ASSEMBLY

CAGE: P/N

Job

No:

Quantity:

HEAT

NUMBER:

Manufacturing Plan

Drawing ID: XXX Rev A

Complete to Print

Op

No

Resource

Operation

Description Date

Qt

y

:

Rej: Person:

5

Purchasing

CAGE:

None

XXX EIPS xxxx IWRC WIRE

ROPE

TYPE I, CLASS 3, CONSTRUCTION 6 PER

RR-W-410

MIN Breaking strength 45

tons

CERTIFICATIONS

REQUIRED

6

Purchasing

CAGE:

Open Socket for X-inch wire

rope

Swage style (S-501) or YYY style

(S-416)

Minimum 45 ton

rating

CERTIFIC

A

TIONS

REQUIRED

10

Fabricate

Wire

Cutter

Cut 1" Domestic Wire Rope to 150 ±1

ft

20

Assemble

National Four

Post

Swa

g

in

g

Machine

Swage socket to wire

rope

30

Inspection

QC

Dept

Inspect sockets after assembly for

after-swage

diameter (1.80 inches max) & record results

for

each assembly. Supply results w/ each

shipment

40

Testing

QC

Dept

Test First Article to failure & record break

strength

(>45 Tons). Supply results w/ first

shipment.

Repeat test if any change in

manufacturing

process or socket t

y

pe

switch.

50

Preperation

for

Deliver

y

Packaging

Dept

Wrap assembly onto a suitable reel with

the

socket end on the inside. Seize & staple

opposite

end to

reel.

Traveler Template: Rev

B

Last Updated:

12/9/2008

Appendix D

Master Tooling Certification

The nature of these parts requires no master tooling and therefore no master

tooling certification is required.

Appendix

E -

Data

Certification

TECHNICAL

DATA RIGHTS

CERTIFICATION LETTER

I

am an officer and employee of the above name legal entity with the responsibility for

investigating

the facts upon which this certification is

made.

To the best of my knowledge and

information

obtained from my recent

investigation:

a. I believe and certify that the technical data submitted to the Defense Supply

Center

Columbus as a

pa1t

of my

company's

request for approval as potential source for the purpose

of

obtaining a contract were obtained by legal means by my company, without breach of

any

contractual or confidential relations pertaining to said technical data by my company, its cmTent

or

recent employees;

and

b.

I

believe and cettify that my company, its cun·ent or recent employees did not

obtain

or receive any technical data marked with a

company's

proprietary rights legend or a

Government

limited rights legend from any U.S.

Governments

agency or employee or other third parties

that

were

used in the preparation of or were incorporated into the request for approval or its

supporting

technical data other than as described herein;

and

c. I certify that my company has the legal right to use said technical data

to

manufacture the below identified part for the United States

Government.

To the extent that

said

technical data are marked with a

company's

proprietary rights or a Government limited

rights

legend or are otherwise believed to be or have in the past been the proprietary data of

another

company, the following

documents

which are attached hereto and made a part of the

certification

have formed the basis for claiming legal right to use said technical

data.

THIS

CERTIFICATION CONCERNS

A MATTER WITHIN THE

JURISDICTION

OF

AN

AGENCY OF THE UNITED STATES AND THE MAKING OF A FALSE, FICTITIOUS,

OR

FRAUDULENT CERTIFICATION

MAY RENDER THE MAKER SUBJECT

TO

PROSECUTION

UNDER THE TITLE 18, UNITED STATES CODE, SECTION

1001.

THIS

CERTIFICATION

APPLIES

TO:

NSN

1640-01-281-5201

PIN

President/CEO Signature block

Appendix F

Qualification Part Sub-Contractor List

P/N 00 – Fabrication and Testing

CAGE:

Phone –

Fax –

P/N 16 – Socket

CAGE:

Phone –

Fax –

P/N 00 – Wire Rope

CAGE: None

Phone –

Source Approval Request

NSN 1640-01-281-5201

Appendix M - Test Plans

Discussion of the TDP:

The TDP was created using samples provided by LMC from the inventory they are using to

support this part for the contracting effort. The design proposed by Company X is an exact

form fit & function equivalent to the current design. In addition to the two unused samples of

the current design and we reviewed a copy of the current drawing package for creation of this

new TDP. The socket is being procured from the same manufacturer of the OEM. The wire is

being procured in accordance with the federal specification RR-W-410 which the current wire

from Wire Co (parent company of YYY) also meets.

Swage vs Spelter Socket:

The Company X design features the swaged YYY socket (01) with the speltered socket (6) as an

optional substitute. Both sockets are made in the USA by YYY Group and meet the dimensional

requirements of the original design. The current TDP shows the same speltered option (drawing

YYY) with the open swage socket listed as an alternate. Company X featured the swaged option

as the primary socket since we wanted to feature the after swage measurement to ensure the

swaging is done correctly if that option was chosen.

Suggested Test Plans:

A destructive test on the first assembly will be performed to ensure the strength requirements are

met or exceeded (drawing YYY note 1). This destructive test will be re-done any time there is a

change in manufacturing process or component supplier. Additionally the after swaged

dimension will be checked on 100% of swaged assemblies per note 5 (see the IMS in appendix

P). Due to the fact that we are using the same materials as the current product and these tests will

ensure that the military is getting a product that meets or exceeds the current assembly we would

suggest that no additional testing be required.

Source Approval Request

NSN 1640-01-281-5201

Appendix N

Licensee Agreement

There is no license agreement between Company X and the OEM and so this

section is not applicable.

Source Approval Request

NSN 1640-01-281-5201

Appendix P

Inspection Method Sheets

Attached are the inspection method sheets for the part we are seeking source approval for. In all

cases we sample with an AQL=0.

Company X

Inc

Cage:

INSPECTION METHOD SHEET

Part Name:

WIRE ROPE ASSY

Part Number:

9230L4000

Rev:

A

Date:

11/23/2009

Contract Number:

n/a

Serial #:

n/a

MP:

Cable Moore

P.O.:

n/a

Heat/Lot No:

n/a

Inspected By:

ź

- Critical Chars - Major Chars

O - Minor Chars

Material:

STEEL (SEE BOM)

Signature: Lot Size: Sampling Plan:

ANSI-Z1.4 Level II, Rej on 1

C/C

Drawing Characteristics

M

easure

d

Tolerance

I

nspec

ti

on

Method

SS A R

ź

1.80 MAX after swaging

Micrometer 100%

151 ± 1 ft

Certified Tape Measure

ź

Break strength greater

than 45 tons (note 1)

Verify test results

and

certification that

no

changes since

testing

occurred

ź

Workmanship

VISUAL

100%

ź

Socket p/n S-501

Verify Crosby Certification 100%

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

REV A - 6/17/2009

IMS Page 1 of 1

Appendix Q

Engine Part Special Requirements

These parts are not part of an engine assembly and therefore this section does

not apply.

Appendix R

Technical Briefing

Upon request of DSCC or any of the Engineering Support Activities,

Company X Inc will be happy to provide a technical briefing.

Appendix S

Sample Part

Sample parts have been manufactured and are available should the ESA like

to review them. Please note that the sample parts only contain 5 feet of cable

in lieu of the required 150 feet as the connection is the only critical portion.

Appendix T

Value Added

There is no additional data essential to the manufacturing of these items that were

not already presented in earlier sections of this source approval request.

Source Approval Request

NSN 1640-01-281-5201