© 2008–2017 TurboChef Technologies, Inc. DOC-1122 / Rev J / October 2017

TurboChef Technologies Inc.

Tornado and Tornado 2 (NGC) Ventless Submittal Information

1. Spec Sheets 1.1

2. UL Ventless Label 2.1

3. UL Listing 3.1

4. UL KNLZ Explained 4.1

5. Test Report 5.1

6. Mechanical Code Sections 6.1

7. Emissions by Product 7.1

8. Fire and Smoke Statement 8.1

9. Heat Loading Calculations 9.1

California 10.1

North Carolina Department of Insurance 10.7

Wisconsin 10.9

Minnesota 10.11

Michigan 10.

12

City of Saint Louis, M

O 10.13

Miami County, OH 10.15

City of Los Angeles 10.17

10. Sampling of Letters from the Following States/Jurisdictions 10.1

11. Surface Temperatures 11.1

12. TurboChef Installation Recommendations 12.1

Project _______________________________________________________

Item No. ______________________________________________________

Quantity _______________________________________________________________________

PERFORMANCE

n

The Tornado

®

evenly and consistently

toasts, browns and crisps food up to 12X

faster than traditional cooking methods,

resulting in a high level of throughput

without compromising quality

THE

TORNADO

®

EXTERIOR CONSTRUCTION

n

430 stainless steel front, top, sides and back

n

4” (102 mm) adjustable legs

n

Cool to the touch pull down door with microwave seal

INTERIOR CONSTRUCTION

n

304 stainless steel interior

n

Fully insulated cook chamber

n

Removable / variable cooking surfaces

n

Exposed bottom browning element

STANDARD FEATURES

n

Integral recirculating catalytic converter for UL 710B (KNLZ) listed

ventless operation

n

Variable-speed High h recirculating impingement airow system

n

Variable cooking surfaces (racks, stones and platters)

n

Independently-controlled bottom browning element

n

Smart Voltage Sensor Technology* (U.S. only)

n

Smart menu system capable of storing up to 128 recipes

n

Built-in self-diagnostics for monitoring oven components and

performance

n

Stackable design (requires stacking kit)

n

Manual snooze mode

n

Includes plug and cord (6 ft. nominal)

n

Smart card compatible

n

Warranty – 1 year parts and labor

COMES WITH STANDARD ACCESSORIES

n

1 Aluminum Paddle (NGC-1478)

n

1 Bottle Oven Cleaner (103180)

n

1 Bottle Oven Guard (103181)

n

2 Trigger Sprayers (103182)

n

2 Non-stick Baskets (100011)

1. Blower Motor

2. Impingement Heater

3. Impinged Air

4. Bottom Browning Element

5. Microwave Bursts

6. Catalytic Converter

1. Blower Motor

2. Impingement Heater

3. Impinged Air

4. IR Element

5. Microwave Bursts

6. Catalytic Converter

1

4

6

2

3

5

TORNADO

®

NGC-1299/Revision M/

October 2012

VENTILATION

n

UL 710B (KNLZ) listed for ventless

operation.

†

n

EPA 202 test (8 hr):

- Product: Pepperoni Pizzas

- Results: 0.21 mg/m

3

- Ventless Requirement: <5.00 mg/m

3

n

Internal catalytic filtration to limit smoke,

grease, and odor emissions.

This product conforms to the ventilation recommendations set forth by NFPA96 using

EPA202 test method.

* Smart Voltage Sensor Technology does not compensate for lack of or over voltage situations. It is the

responsibility of the owner to supply voltage to the unit according to the specications on the back of this sheet.

†

Ventless certication is for all food items except for foods classied as “fatty raw proteins.” Such foods include

bone-in, skin-on chicken, raw hamburger meat, raw bacon, raw sausage, steaks, etc. If cooking these types of

foods, consult local HVAC codes and authorities to ensure compliance with ventilation requirements.

Ultimate ventless allowance is dependent upon AHJ approval, as some jurisdictions may not recognize the

UL certification or application. If you have questions regarding ventless certifications or local codes please

email ventless.help@turbochef.com

TurboChef reserves the right to make substitutions of components or change specications without prior notice.

DIMENSIONS

Single Units

Height 19” 483 mm

on legs 23” 584 mm

Width 26” 660 mm

Depth 25.7” 653 mm

with handle 28.2” 716 mm

Weight 190 lbs. 86 kg

Stacked Units

(Stacking Kit Required)

Height 38” 965 mm

Width 26” 660 mm

Depth 25.7” 653 mm

with handle 28.2” 716 mm

Weight 380 lbs. 172 kg

Cook Chamber

H

eight 8” 203 mm

Width 15.5” 394 mm

Depth 14.7” 373 mm

Volume 1.05 cu.ft. 29.9 liters

Wall Clearance

(Oven not intended for built-in installation)

Top 4” 102 mm

Sides 2” 51 mm

ELECTRICAL SPECIFICATIONS

NORTH AMERICA

NGC (NGC-1180-1)

Phase 1 Phase

Voltage 208/240 VAC

F

requency 60 Hz

Current 30 amp

Max Circuit Requirement 30 amp

Plug/Cord NEMA 6-30P; 1.5m,

H07RN-F

Max Input 5990/6675 watts

M

icrowave Input Power 3500 watts

NGCBK (NGC-1180-1K-2020)

Phase 1 Phase

Voltage 220 VAC

Frequency 60

Hz

Current 30 amp

Max C

ircuit Requirement 30 amp

Plug IEC 309, 3-pin, 32 amp

Max Input 6700 watts

Microwave Input Power 3500 watts

EUROPE/ASIA-PACIFIC

NGCEW (NGC-1180-1W for standard)

NGCEW (NGC-1180-1W

-2024 for Australia/New Zealand)*

NGCKW (NGC-1180-1W-2004 for

South Korea)**

Phase 3 Phase

Voltage 400 VA

C

Frequency 50

Hz or 60 Hz**

Current 16 amp

Max Circuit Requirement 20 amp

Plug IEC 309, 5-pin, 32 amp

Max Input 10500 watts

Microwave Input Power 3500 watts

NGCED (NGC-1180-1D)

Phase 3 Phase

Voltage 230 VAC

Frequency 50

Hz

Current 30 amp

Max C

ircuit Requirement 32 amp

Plug IEC 309, 4-pin, 32 amp

Max Input 10500 watts

Microwave Input Power 3500 watts

NGC

UK (NGC-1180-1K)

Phase 1 Phase

Voltage 230 V

AC

Frequency 50 Hz

Current 30 amp

Max Circuit Requirement 32 amp

Plug IEC 309, 3-pin, 32 amp

Max Input 6700 watts

Microwave Input Power 3500 watts

J

APAN

NGCJD - 50Hz/ 3 Phase (NGC-1180-1D-2005-1)

NGCJ

D - 60Hz/ 3 Phase (NGC-1180-1D-2005-2)

NGCJK - 50

Hz/ 1 Phase (NGC-1180-1K-2005-3)

NGCJK - 60

Hz/ 1 Phase (NGC-1180-1K-2005-4)

Phase 1 or 3 Phase

Voltage 200 V

AC

Frequency 50 or 60

Hz

Current 30 amp

Max C

ircuit Requirement 30 amp

Plug P

SE-marked, 3 or 4-blade, 30 amp

Max I

nput 10500 or 6700 watts

Microwave Input Power 3500 watts

SHIPPING INFORMATION

U.S.: All ovens shipped within the U.S. are packaged in a double-wall cor-

rugated box banded to a wooden skid.

International: All I

nternational ovens shipped via Air or Less than Con-

tainer Loads are packaged in wooden crates.

Box size: 34” x 30” x 30” (864 mm x 762 mm x 762 mm)

Crate size: 37”x 33” x 34” (940 mm x 838 mm x 864 mm)

Item class: 85 NMFC #26770

HS code 8419.81

Approxima

te boxed weight: 260 lb. (118 kg)

Approximate crated weight: 320 lb. (145 kg)

Minimum entry clearance required for box: 30.5” (775 mm)

Minimum entry clearance required for crate: 33.5” (851 mm)

*All AU-New Zealand ovens with clips allow for 5 pin plug.

TurboChef recommends installing a type D circuit breaker for all installations.

Standard

Australia/New Zealand

3-Phase

1-Phase

TORNADO

®

26” (660 mm)

11.25” (286 mm)

25.7” (653 mm)

23”

(584 mm)

19”

(483 mm)

TurboChef Global Operations

4240 International Pkwy, Suite 105 / Carrollton, Texas 75007 USA

US: 800.90TURBO (800.908.8726) / International: +1 214.379.6000

Fax: +1 214.379.6073 / turbochef.com

Project _______________________________________________________

Item No. ______________________________________________________

Q u a n t i t y _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _______________________________________

PERFORMANCE

The Tornado 2

TM

oven evenly and

consistently toasts, browns, and crisps food

up to twelve times faster than traditional

cooking methods, resulting in a high level

of throughput without compromising

quality.

TORNADO 2

TM

EXTERIOR CONSTRUCTION

n

Stainless steel exterior with powder-coated side panels

n

4” (102 mm) legs

n

Cool to the touch pull down door with microwave seal

INTERIOR CONSTRUCTION

n

304 stainless steel interior

n

Fully insulated cook chamber

n

Removable / variable cooking surfaces

n

Exposed bottom browning element

STANDARD FEATURES

n

Integral recirculating catalytic converter for UL 710B (KNLZ) listed

ventless operation

n

Variable-speed High h recirculating impingement airflow system

n

Variable cooking surfaces (racks, stones, and platters)

n

Independently-controlled bottom browning element

n

Smart Voltage Sensor Technology* (U.S. only)

n

Smart menu system capable of storing up to 128 recipes

n

Built-in self-diagnostics for monitoring oven components

and performance

n

Stackable design (requires stacking kit)

n

Manual snooze mode

n

Includes plug and cord (6 ft. nominal)

n

Smart card compatible

n

Warranty – 1 year parts and labor

COMES WITH STANDARD ACCESSORIES

n

1 Aluminum Paddle (NGC-1478)

n

1 Bottle Oven Cleaner (103180)

n

1 Bottle Oven Guard (103181)

n

2 Trigger Sprayers (103182)

n

2 Non-stick Baskets (100011)

1. Blower Motor

2. Impingement Heater

3. Impinged Air

4. Bottom Browning Element

5. Microwave Bursts

6. Catalytic Converter

1. Blower Motor

2. Impingement Heater

3. Impinged Air

4. IR Element

5. Microwave Bursts

6. Catalytic Converter

1

4

6

2

3

5

VENTILATION

n

UL 710B (KNLZ) listed for ventless

operation.

†

n

EPA 202 test (8 hr):

- Product: Pepperoni Pizzas

- Results: 0.21 mg/m

3

- Ventless Requirement: <5.00 mg/m

3

n

Internal catalytic filtration to limit smoke,

grease, and odor emissions.

TORNADO 2

TM

DOC-1134/Revision H/

October 2012

This product conforms to the ventilation recommendations set forth by NFPA96 using

EPA202 test method.

* Smart Voltage Sensor Technology does not compensate for lack of or over voltage situations. It is the

responsibilityoftheownertosupplyvoltagetotheunitaccordingtothespecicationsonthebackofthissheet.

†

Ventlesscerticationisforallfooditemsexceptforfoodsclassiedas“fattyrawproteins.”Suchfoodsinclude

bone-in, skin-on chicken, raw hamburger meat, raw bacon, raw sausage, steaks, etc. If cooking these types of

foods, consult local HVAC codes and authorities to ensure compliance with ventilation requirements.

Ultimate ventless allowance is dependent upon AHJ approval, as some jurisdictions may not recognize the

UL certification or application. If you have questions regarding ventless certifications or local codes please

email [email protected]

TurboChefreservestherighttomakesubstitutionsofcomponentsorchangespecicationswithoutpriornotice.

DIMENSIONS

Single Units

Height 19” 483 mm

on legs 23” 584 mm

Width 26” 660 mm

Depth 25.7” 653 mm

with handle 28.45” 723 mm

Weight 190 lb. 86 kg

Stacked Units

(Stacking Kit Required)

Height 38” 965 mm

Width 26” 660 mm

Depth 25.7” 653 mm

with handle 28.45” 723 mm

Cook Chamber

Height 8” 203 mm

Width 15.5” 394 mm

Depth 14.7” 373 mm

Volume 1.05 cu.ft. 29.9 liters

Wall Clearance

(Oven not intended for built-in installation)

Top 4” 102 mm

Sides 2” 51 mm

ELECTRICAL SPECIFICATIONS

NORTH AMERICA (NGC-1280-1)

Phase 1 Phase

Voltage 208/240 VAC

Frequency 60 Hz

Current 30 amps

Max Circuit Requirement 30 amps

Plug/Cord NEMA 6-30P; 1.5m, H07RN-F

Max Input 5,990 watts (208) / 6,675 watts (240)

Microwave Input Power 3,500 watts

NGCBK (NGC-1280-1K-2020)

Phase 1 Phase

Voltage 220 VAC

Frequency 60 Hz

Current 30 amps

Max Circuit Requirement 30 amps

Plug IEC 309, 3-pin, 32 amp

Max Input 6,700 watts

Microwave Input Power 3,500 watts

EUROPE/ASIA-PACIFIC

NGCEW (NGC-1280-1W for standard)

NGCEW (NGC-1280-1W-2024 for Australia/New Zealand)*

NGCKW (NGC-1280-1W-2004 for South Korea)**

Phase 3 Phase

Voltage 400 VAC

Frequency 50 Hz or 60 Hz**

Current 16 amps

MaxCircuitRequirement 20 amps

Plug IEC 309, 5-pin, 32 amp

Max Input 10,500 watts

Microwave Input Power 3,500 watts

NGCED (NGC-1280-1D)

Phase 3 Phase

Voltage 230 VAC

Frequency 50 Hz

Current 30 amps

MaxCircuitRequirement 30 amps

Plug IEC 309, 4-pin, 32 amp

Max Input 10,500 watts

Microwave Input Power 3,500 watts

NGCUK (NGC-1280-1K)

Phase 1 Phase

Voltage 230 VAC

Frequency 50 Hz

Current 30 amps

Max Circuit Requirement 32 amps

Plug IEC 309, 3-pin, 32 amp

Max Input 6,700 watts

Microwave Input Power 3,500 watts

JAPAN

NGCJD - 50Hz/ 3 Phase (NGC-1280-1D-2005-1)

NGCJD - 60Hz/ 3 Phase (NGC-1280-1D-2005-2)

NGCJK - 50Hz/ 1 Phase (NGC-1280-1K-2005-3)

NGCJK - 60Hz/ 1 Phase (NGC-1280-1K-2005-4)

Phase 1 or 3 Phase

Voltage 200 VAC

Frequency 50 or 60 Hz

Current 30 amps

Max Circuit Requirement 30 amps

Plug PSE-marked, 3 or 4-blade, 30 amp

Max Input 6,700 or 10,500 watts

Microwave Input Power 3,500 watts

SHIPPING INFORMATION

U.S.: All ovens shipped within the U.S. are packaged in a double-wall

corrugated box banded to a wooden skid.

International: All International ovens shipped via Air or Less than Container

Loads are packaged in wooden crates.

Box size: 34” x 30” x 30” (864 mm x 762 mm x 762 mm)

Crate size: 37”x 33” x 34” (940 mm x 838 mm x 864 mm)

Item class: 85 NMFC #26770 HS code 8419.81

Approximate boxed weight: 260 lb. (118 kg)

Approximate crated weight: 320 lb. (145 kg)

Minimum entry clearance required for box: 30.5” (775 mm)

Minimum entry clearance required for crate: 33.5” (851 mm)

*All AU-New Zealand ovens with clips allow for 5 pin plug.

TurboChef recommends installing a type D circuit breaker for all installations.

Standard

Australia/New Zealand

3-Phase

1-Phase

TurboChef Global Operations

4240 International Pkwy, Suite 105 / Carrollton, Texas 75007 USA

US: 800.90TURBO (800.908.8726) / International: +1 214.379.6000

Fax: +1 214.379.6073 / turbochef.com

TORNADO 2

TM

26” (660 mm)

19”

(483 mm)

25.7” (653 mm)

11.5”

(292 mm)

23”

(584 mm)

© 2009-2010 TurboChef Technologies, Inc.

Page 2.1

[Heaters and Heating Equipment] (Heaters, Cooking Appliances) Commercial

Cooking Appliances with Integral Systems for Limiting the Emission of Grease-

laden

Air

See General Information for Heaters, Cooking Appliances

This category covers cooking equipment intended for commercial use, such as pressurized deep fat fryers and other appliances for use in commercial

kitchens, restaurants or other business establishments where food is prepared. Each appliance covered in this category is manufactured with an

integral system feature to limit the emission of grease-laden air from the cooking process to the room ambient.

These appliances have been evaluated for the limit of 5 mg/m

3

for the emission of grease-laden air to the room ambient in accordance with the

recommendations of the National Fire Protection Association Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations,

NFPA 96, using the EPA-202 test method prescribed for cooking appliances provided with integral recirculating air systems.

These products are not intended for connection to a ducted exhaust system.

Appliances in this category are not provided with an integral fire extinguishing system. Authorities having jurisdiction should be consulted as to the

requirements for this equipment with respect to fire extinguishing systems, such as the need for field installed systems in accordance with NFPA 96.

For products with integral recirculating systems including fire extinguishing systems, refer to Commercial, with Integral Recirculating Systems (KNKG).

In cases where the nature or construction of equipment is such that special precautions beyond the requirements of the National Electrical Code must

be observed in installations or use, suitable warning or special instructions are marked on the equipment.

Appliances Listed in this category are suitable for wiring with either copper or aluminum power supply conductors unless marked "Use Copper Wire

Only For Power Supply Connections" .

Commercial cooking appliances of certain types are designed for permanent connections to water supply and sewer lines at the point of installation.

Authorities having jurisdiction should be consulted as to the requirements for this equipment with respect to sanitation and connection to water supply

and waste disposal lines.

Neither the toxicity of coatings nor the physiological effects on persons consuming food products prepared by use of these appliances has been

investigated.

For cooking oil filters that are not an integral part of another appliance, see Commercial Filters for Cooking Oil (KNRF

).

For additional information, see Electrical Equipment for Use in Ordinary Locations (AALZ) and Heating, Cooling, Ventilating and Cooking Equipment

(AAHC).

The basic standard used to investigate products in this category is ANSI/UL 197, "Commercial Electric Cooking Appliances".

Appliances Listed in this category with an integral cooking oil filter have been additionally investigated to the requirements in the standard "

Commercial

Filters for Cooking Oil", ANSI/UL 1889.

The Listing Mark of Underwriters Laboratories Inc. on the product is the only method provided by UL to identify products manufactured under its Listing

and Follow-Up Service. The Listing Mark for these products includes the name and/or symbol of Underwriters Laboratories Inc. (as illustrated in the

Introduction of this Directory) together with the word "LISTED," a control number and one of the following product names as appropriate: "Commercial

Cooking Appliance," "Cooking Appliance," or other appropriate product identity specified in the individual Listing, along with the words "with integral

system for limiting the emission of grease-laden air. "

KNLZ.GuideInfo

Commercial Cooking Appliances with Integral Systems for Limiting the Emission of

Grease-laden Air

View Listings Page Bottom

KNLZ.GuideInfo

-

Commercial Cooking Appliances with Integral Systems for Limiting the Emission of

...

8/28/2008

http://database.ul.com/cgi

-

bin/XYV/template/LISEXT/1FRAME/showpage.html?&name=KNLZ.GuideI

...

Page 4.1

Copyright © 2008 Underwriters Laboratories Inc.®

The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured under

UL's Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed and covered under UL's Follow-Up Service. Always

look for the Mark on the product.

UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide Information,

Designs and/or Listings (files) must be presented in their entirety and in a non-

misleading manner, without any manipulation of the data (or drawings).

2. The statement "Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc." must appear adjacent to the

extracted material. In addition, the reprinted material must include a copyright notice in the following format: "Copyright © 2008 Underwriters

Laboratories Inc.®"

Last Updated on 1999-02-19

Questions? Notice of Disclaimer Page Top

KNLZ.GuideInfo

-

Commercial Cooking Appliances with Integral Systems for Limiting the Emission of

...

8/28/2008

http://database.ul.com/cgi

-

bin/XYV/template/LISEXT/1FRAME/showpage.html?&name=KNLZ.GuideI

...

Page 4.2

Page 5.1

Page 5.2

EXHAUST SYSTEMS

airfrom the exhaust outlet discharges away from such

locations.

506.4 Ducts serving Type

II

hoods. Single or combined Type

II exhaust systems for food-processing operations shall be

independent

of

all other exhaust systems. Commercial kitchen

exhaust systems serving Type II hoods shall comply with Sec-

tions 506.4.1 and 506.4.2.

506.4.1 Type

II

exhaust outlets. Exhaust outlets for ducts

serving Type II hoods shall comply with Sections 401.4 and

401.4.2. Such outlets shall be protected against local

weather conditions and shall meet the provisions for exte-

rior wall opening protectives in accordance with the

Inter-

national Building Code.

506.4.2 Ducts. Ducts and plenums serving Type II hoods

shall be constructed

of

rigid metallic materials. Duct con-

struction, installation, bracing and supports shall comply

with Chapter

6.

Ducts subjectto positive pressure and ducts

conveying moisture-laden or waste-heat-Iaden air shall be

constructed, joined and sealed in an approved manner.

506.5 Exhaust equipment. Exhaust equipment, including

fans and grease reservoirs, shall comply with Sections 506.5.1

through 506.5.5 and shall be

of

an approved design or shall be

listed for the application.

506.5.1 }:xhaustfans. Exhaust fan housings serving a Type

I hood shall be constructed

as

required for grease ducts in

accordance with Section 506.3.1.1.

Exception: Fans listed and labeled in accordance with

UI-I762.

506.5.1.1

Fan

motor. Exhaust fan motors shall be

located outside

of

the exhaust airstream.

506.5.2 Exhaustfan discharge. Exhaust fans shall be posi-

tioned so that the discharge will not impinge on the roof,

other equipment or appliances or parts

of

the structure. A

vertical discharge fan shall be manufactured with an

approved drain outlet at the lowest point

of

the housing to

permit drainage

of

grease to an approved grease reservoir.

506.5.3 Exhaust fan mounting. An upblast fan shall be

hinged and supplied with a flexible weatherproof electrical

cable to permit inspection and cleaning. The ductwork shall

extend a minimum

of

18

inches (457 mm) above the roof

surface.

506.5.4 Clearances. Exhaust equipment serving a Type I

hood shall have a clearance to combustible construction

of

not less than

18

inches (457 mm).

Exception: Factory-builtexhaust equipment installed in

accordance with Section 304.1 and listed for a

l,~sser

clearance. '

506.5.5 Terminationlocation. The outlet

of

exhaustequip-

ment serving Type I hoods shall be in accordance with Sec-

I tion 506.3.12.

Exception: The minimum horizontal distance between

vertical discharge fans and parapet-type building struc-

tures shall be 2 feet (610 mm) provided that such struc-

44

tures are not higher than the top

of

the fan discharge

opening.

SECTION 507

COMMERCIAL KITCHEN HOODS

507.1 General. Commercial kitchen exhaust hoods shall com-

ply with the requirements

of

this section. Hoods shall be Type I

orType II and shall be designed to capture and confine cooking

vapors and residues. Commercial kitchen exhaust hood sys-

I

tems shall operate during the cooking operation.

Exceptions:

1.

Factory-built commercial exhaust hoods which are

tested in accordance with UL 710, listed, labeled and

installed in accordance with Section 304.1 shall not

be required to comply with Sections 507.4, 507.7,

507.11,507.12,507.13,507.14 and 507.15.

2.

Factory-built commercial cooking recirculating sys-

tems which are tested in accordance with UL 710B,

I

listed, labeled and installed in accordance with Sec-

tion 304.1 shall not be required to comply with Sec-

tions 507.4,507.5,507.7,507.12,507.13,507.14and

507.15.

3.

Net exhaust volumes for hoods shall be permitted to

bereduced during no-load cooking conditions, where

engineered or listed multispeed or variable-speed

controls automatically operate the exhaust system to

maintain capture and removal

of

cooking effluents as

required by this section.

507.2 Where required. A Type I or Type II hood shall be

installed at or above all commercial cooking appliances in

accordance with Sections 507.2.1 and 507.2.2. Where any

cooking appliance under a single hood requires a Type I hood, a

Type I hood shall be installed. Where a Type II hood is

required, a Type I or Type II hood shall be installed.

..

507.2.1 Type I hoods. Type I hoods shall be installed where

cooking appliances produce grease or smoke, such as

occurs with griddles, fryers, broilers, ovens, ranges and wok

ranges.

507.2.1.1 Operation. Type I hood systems shall be

designed and installed to automatically activate the

exhaust fan whenever cooking operations occur. The

activation

of

the exhaust fan shall occur through an inter-

lock with the cooking appliances, by means

of

heat sen-

sors or by means

of

other approved methods.

507.2.2. Type

II

hoods. Type II hoods shall be installed

where cooking or dishwashing appliances produce heat,

steam, or products

of

combustion and do not produce grease

or smoke, such

as

steamers, kettles, pasta cookers and

dishwashing machines.

Exceptions:

1.

Under-counter-type commercial dishwashing

machines.

2.

A Type II hood is not required for dishwashers and

potwashers that are provided with heat and water

2006 INTERNATIONAL

MECHANICAL

CODE@

vapor exhaust systems that are supplied by the

appliance manufacturer and are installed in accor-

dance with the manufacturer's instructions.

....

3.

A single light-duty electric convection, bread,

retherm or microwave oven. The additional heat

and moisture loads generated by such appliances

shall be accounted for in the design

of

the HVAC

system.

4. A Type II hood is not required for the following

electrically heated appliances: toasters, steam

tables, popcorn poppers, hot dog cookers, coffee

makers, rice cookers, egg cookers, holding/warm-

ing ovens. The additional heat and moisture loads

generated by such appliances shall be accounted

for in the design

of

the HVAC system.

507.2.3 Domestic cooking appliances used for commer-

cial purposes.

Domestic cooking appliances utilized for

commercial purposes shall be provided with Type I orType

II hoods

as

required for the type

of

appliances and processes

in accordance with Sections 507.2, 507.2.1 and 507.2.2.

507.2.4 Extra-heavy-duty. Type I hoods for use over

extra-heavy-duty cooking appliances shall not cover other

appliances that require fire extinguishing equipment and

such hoods shall discharge to an exhaust systemthatis inde-

pendent

of

other exhaust systems.

507.3 Fuel-burning appliances. Where vented fuel-burning

appliances are located in the same room or space as the hood,

provisions shallbe made to preventthe hood system from inter-

fering with normal operation

of

the appliance vents.

507.4 Type I materials. Type I hoods shall be constructed

of

steel notless than 0.043 inch (1.09 mm) (No.

18

MSG) in thick-

ness, or stainless steel not less than 0.037 inch (0.94 mm) (No.

20 MSG) in thickness.

507.5 Type

II

hood materials. Type II hoods shall be con-

structed

of

steel not less than 0.030 inch (0.76 mm) (No. 22

Gage) in thickness, stainless steel not less than 0.024 inch (0.61

mm) (No. 24 Gage) in thickness, copper sheets weighing not

less than 24 ounces per square foot (7.3 kg/m

2

),

or

of

other

approved material and gage.

507.6 Supports. Type I hoods shallbe secured in placeby non-

combustible supports. All Type I and Type II hood supports

shall be adequate for the applied load

of

the hood, the unsup-

ported ductwork, the effluent loading, and the possible weight

of

personnel working in or on the hood.

507.7 Hood joints, seams

and

penetrations. Hood joints,

seams and penetrations shall comply with Sections 507.7.1 and

507.7.2.

507.7.1 Type I hoods. External hoodjoints, seams and pen-

etrations for Type I hoods shall be made with a continuous

external liquid-tight weld or braze to the lowest outermost

perimeter

of

the hood. Internal hoodjoints, seams, penetra-

tions, filter support frames, and other appendages attached

2006

INTERNATIONAL

MECHANICAL

CODE@

EXHAUST SYSTEMS

inside the hood shall not be required to be welded or brazed

but shall be otherwise sealed to be grease tight.

Exceptions:

1.

Penetrations shall not be required to be welded or

brazed where sealed by devices that are listed for

the application.

2.

Internal welding or brazing

of

seams, joints, and

penetrations

of

the hood shall not be prohibited

provided that thejointis formed smooth or ground

so as to not trap grease, and is readily cleanable.

507.7.2 Type

II

hoods. Joints, seams and penetrations for

Type II hoods shall be constructed as set forth in Chapter

6,

shallbe sealed on the interior

of

the hood and shall provide a

smooth surface that is readily cleanable and water tight.

507.8 Cleaning

and

grease gutters. A hood shall be designed

to provide for thorough cleaning

of

the entire hood. Grease gut-

ters shall drain to an approved collection receptacle that is fab-

ricated, designed and installed to allow access for cleaning.

507.9 Clearances for Type I hood. A Type I hood shall be

installed with a clearance to combustibles

of

not less than

18

inches (457 mm).

Exception: Clearance shall not be required from gypsum

wallboard attached to noncombustible structures provided

thata smooth, cleanable, nonabsorbent and noncombustible

material is installedbetween the

h90d and the gypsum wall-

board over an area extending not less than

18

inches (457

mm) in all directions from the hood.

507.10 Hoods penetrating a ceiling. Type I hoods or portions

thereofpenetrating a ceiling, wall orfurred space shall comply

with all the requirements

of

Section 506.3.10.

507.11 Grease filters. Type I hoods shall be equipped with

listed grease filters designed for the specific purpose.

Grease-collecting equipment shall be provided with access for

cleaning. The lowest edge

of

a grease filter located above the

cooking surface shall be not less than the height specified in

Table 507.11.

TABLE

507.11

MINIMUM DISTANCE BETWEEN THE LOWEST EDGE OF A

GREASE FILTER

AND

THE COOKING SURFACE OR THE

HEATING SURFACE

TYPE

OF

COOKING

HEIGHT ABOVE COOKING

APPLIANCES

SURFACE (feet)

Without exposed flame 0.5

Exposed flame and burners

2

Exposed charcoal and charbroil type 3.5

For

SI:

1 foot =304.8

mm.

507.11.1 Criteria. Filters shall be

of

such size, type and

arrangement as will permit the required quantity

of

air to

pass through such units at rates not exceeding those for

which the filter or unit was designed

or' approved. Filter

units shall be installed in frames or holders so as to be

readily removable without the use

of

separate tools, unless

45

Page 6.1

UL 710B (KNLZ)

Emissions by Product

0

25

50

75

100

125

150

175

200

225

250

275

C3/C HHB i5 NGC

TurboChef Model

Product Cooked per 8 hour period

0

0.25

0.5

0.75

1

1.25

1.5

1.75

2

2.25

2.5

2.75

3

PM Emissions [ppm]

Pizza's Cooked

Emissions

Page 7.1

C:\Windows\Temp\Rar$DI00.000\Fire smoke and grease statement v2_11.doc

October 18, 2004

Mr. Mike Denny

Building Services,

224 West Knight St.

City of Sioux Falls,

South Dakota, 57102

Ph: 605-367-8252

Re: Fire and smoke containment

Dear Mr. Denny:

The TurboChef ovens have been extensively tested and conform to UL 923 and UL KNLZ

standards. The UL 923 standard is the electrical/product safety standard and the KNLZ is the low particulate matter

emissions standard to which we conform. While both standards address difference aspects of the oven, they both

have inherent overlap as it relates to grease/smoke/fire handling.

As it relates specifically to fire safety, UL 923 specifies:

Section 57 Cavity Fire Containment Test:

The performance of an appliance subjected to this test shall be considered

acceptable if all of the following conditions are met:

a) There is no emission of fire, flame, or molten metal outside the appliance nor glowing or ignition

of the cheesecloth, tissue paper, or wood surface;

b) The fuse rated 3 A does not open;

c) Following the test, the appliance complies with the requirements of Leakage Current, Section 33,

and Dielectric Voltage-Withstand Test, Section 39, as applicable to primary circuits; and

d) Following the test and following 10 c of operation (opening and closing the door), the

appliance complies with the requirements in 57.12. The radiation emission shall not xceed

5mW/cm2.

Test Method:

Section 57.2 requires that 4 potatoes each weighing between 150g and 200g be placed inside the

oven under test and cooked using full microwave power and hot air (if applicable) until the potatoes

catch fire. Note: The test must be repeated until it catches fire. During this test, pieces of tissue

paper and cheesecloth are placed above, below and around the product to ensure that the fire

and/or excessive heat generated is safely contained within the confines of the appliance.

As it relates to grease handling, UL KNLZ specifies:

UL KNLZ Guide Information Excerpt:

“These appliances have been evaluated for the limit of 5 mg/m

3

for the emission of grease-laden

air to the room ambient in accordance with the recommendations of the National Fire Protection

Association Standard for Ventilation Control and Fire Protection of Commercial Cooking

Operations, NFPA 96, using the EPA-202 test method prescribed for cooking appliances provided

with integral recirculating air systems.”

Page 8.1

C:\Windows\Temp\Rar$DI00.000\Fire smoke and grease statement v2_11.doc

Test Method:

The UL KNL

Z category requires that products must have less than 5.0 mg/m3 of particulate matter

emissions during 8 continuous hours of cooking a “worst case” food product as measured by EPA

202. Note: Our products were tested using full-fat pepperoni pizzas.

As it pertains specifically to smoke: Smoke typically consists of visible grease particulate that escapes from a product

during operation. Our ovens utilize a recirculating airpath that is catalytic scrubbed, thus the airborne grease is

combusted as it crosses our catalyst. Given this, under typical/normal operating conditions, our product does not emit

smoke.

If you have any issues or specific questions regarding the above, please contact me directly.

Best regards,

James K. Pool III

James K. Pool III

Vice President Engineering,

TurboChef Technologies, Inc.,

Ph: 214.379.6020

Email: [email protected]

Page 8.2

NGC Energy.xls

NGC Tornado (1 PHASE)

Changeable Parameters

Operating Time 12 Hours

Energy Costs $0.11 kWHr

Snooze Mode 0.00 Hours

Cook Cycles/Day 100 Cooks/Day

Typical Cook Time 60 Seconds

Do Not Change the following values

Time (min)

Power

(Watts) Cost/Day Balance of Time (hrs)

Warm up

15 5277 $0.15 11.75

Cooking

100

5000

$0.96

10.08

Snooze Idle

0

1100

$0.00

10.08

Idle

605

1400

$1.62

0

Total/Day

$2.72 Yearly

Total/Month

$81.72

$980.62

HVAC Requirements Per Operating Time -- Note: Approximations Only

Average Energy Cooking And Idle (J) Warmup Energy (J)

Total

Energy (J)

Total average

Power (W)

Total Environmental

Load kBtu/hr

Average

Cooling

Requirement

(ton of AC)

80820000

4749300

85569300

1981

6.759028

0.563

11/6/2008 Confidential James K. Pool

Page 9.1

ARNOLD SCHWARZENEGGER

Gover

nor

State of California—Health and Human Services Agency

Department of Health Services

SANDRA SHEWRY

D

irector

July 23, 2004

Ruth Sender

OhCal Foods, Inc.

20501 Ventura Blvd., Suite 375

Woodland Hills, CA 91364

RE: Exemption from Mechanical Exhaust Ventilation for

TurboChef Model NGC Rapid Cook Oven

Dear Ms. Sender:

Thank you for your application of April 26, 2004, for a review of the TurboChef Model

NGC Rapid Cook Oven for exemption from the mechanical exhaust ventilation

requirements of Section 114140 of the California Uniform Retail Food Facilities Law

(CURFFL). Specifically, you have requested an exemption to allow unventilated NGC

Rapid Cook Ovens to be installed and operated at various Subway locations throughout

California.

You have provided documentation and I have verified that the TurboChef Model NGC

Rapid Cook Oven has been evaluated and listed by UL for conformance with ANSI/NSF

Standard 4.

Under the provisions of CURFFL Section 114140, the Department may exempt heating

and cooking equipment that does not produce toxic gases, grease, smoke, or heat

when properly installed and operated as recommended by the manufacturer. Based on

the information and documentation you have provided, the TurboChef Model NGC

Rapid Cook Oven is granted LIMITED exemption from mechanical exhaust ventilation

under the following conditions:

1. Unless approval is granted by the local enforcement agency, there shall be no

more than one unventilated oven in operation at each Subway location.

2. No other heating or cooking appliances subject to mechanical ventilation

requirements may be operated without mechanical ventilation in the food

facility, unless permission to operate more than one unventilated appliance is

granted by the local enforcement agency.

Food and Drug Branch, MS 7602, P.O. Box 997413, Sacramento, CA 95899-7413

Intern

e

t

A

d

dress:

www.dhs.ca.gov/fdb

3

Page 10.1

Ms. Ruth Sender

J

uly

23, 2004

Page 2

3. The oven shall not be used for cooking

meats, poultry, fish, or other foods

that may produce grease laden vapors. Such use will require that mechanical

ventilation be installed over the unit.

4. The oven must be operated and installed in a well-ventilated area approved

for food preparation.

5. The oven must be installed, maintained, operated, and serviced according to

the specifications of the manufacturer and local codes.

6. This exemption shall not be deemed to supersede any local fire or building

code requirements.

This exemption shall be in effect until revoked. However, should any local enforcement

agent find that the operation of the TurboChef Model NGC Rapid Cook Oven without

mechanical ventilation creates a sanitation or safety problem, the local enforcement

agent may require the unit to be used only with mechanical ventilation. These problems

may include, but are not limited to, problems of installation, use, maintenance, cleaning

or other site specific considerations which exceed the above limitations or pose a

discernable health or safety hazard.

This letter may be used as evidence of the evaluation of the TurboChef Model NGC

Rapid Cook Oven. However, it is not to be construed as an endorsement of the subject

item and may not be used for advertising or promotional purposes.

If you have any questions you may call me at (916) 650-6617.

Sincerely,

Susan Strong, REHS

Program Specialist, Retail Food Unit

Cc: Mike Boian, REHS

Northern California Technical Advisory Committee

Page 10.2

Ms. Ruth Sender

J

uly

23, 2004

Page 3

Virginia Lineberry, REHS

Bay Area Te

chnical Advisory Committee

Donna Fenton, REHS

Central Valley Technical Advisory Committee

Nelson Kerr, REHS

Southern California Technical Advisory Committee

Gary Erbeck, REHS

CCDEH, Food Safety Policy Committee

Page 10.3

GRAY DAVIS

Govern

or

State of California—Health and Human Services Agency

Department

of Health Services

Food & Drug Branch

Do your part to help California save energy. To lear

n more abo

ut saving energy, visit the following web site:

www.consumerenergycenter.org/flex/index.html

601 N. 7

th

Street, MS-357, P.O. Box 942732, Sacramento, CA, 94234-7320

(916) 445-2263

Internet Address:

www.dhs.ca.gov

DIANA M. BONT

Á, R.N., D

r. P.H.

Director

October 25, 2002

Peter J. Ashc

raft

TurboChef Technologies, Inc.

10500 Metric Drive, Suite 128

Dallas, Texas 75243

Dear Mr. Ashcraft:

RE: Exemption from External Mechanical Exhaust Ventilation

Thank you for your letter of October 7, 2002 requesting exemption from mechanical

exhaust ventilation requirements specified in Section 114140 of the California Uniform Retail

Food Facilities Law (CURFFL) for the Model C3/C Rapid Cook Oven.

Descriptive materials and cut sheets accompanying your application specify that this

oven is Sanitation Classified by NSF International for compliance with ANSI/NSF Standard 4

for commercial heating and cooking appliances.

Under the provisions of Section 114140, the Department may exempt heating and

cooking equipment that does not produce toxic gases, grease, smoke, or heat when properly

installed and operated as recommended by the manufacturer. Results of tests conducted by the

Pacific Gas & Electric, Food Service Technology Center, indicate that the oven produces no

significant emissions of smoke and grease-laden air while in use. Based on the information you

have provided and the certifications by recognized testing laboratories, the TurboChef

Technologies Model C3/C Rapid Cook Oven is granted LIMITED exemption from mechanical

ventilation requirements under the following conditions:

1. There may be up to two (2) unventilated Model C3/C ovens in Subway sandwich

stores in California.

2. The oven(s) must be installed, maintained, operated, and serviced according to the

specifications of the manufacturer and local codes.

3. Any modification, alteration, or removal of any component of the integral air

filtration system voids this limited exemption.

4. All air filtration components must be installed and operational at all times the

appliance is in use.

5. The oven must be installed in an approved food preparation area with sufficient room

ventilation to maintain acceptable working conditions.

Page 10.4

Peter Ashcraft

October 25

, 2002

This exemption shall be in effect until revoked. However, should any local enforcement

agent find that the operation of the TurboChef Technologies Model C3/C Rapid Cook Oven

without mechanical ventilation creates a sanitation or safety problem, the local enforcement

agent may require the unit to be used only with external mechanical ventilation. These problems

may include but are not limited to problems of installation, use, maintenance, cleaning or other

site specific considerations which exceed the above limitations or pose a discernable health or

safety problem.

This letter may be used as evidence of the evaluation of the TurboChef Model C3/C

Rapid Cook Oven. However, it is not to be construed as an endorsement of the subject

equipment and may not be used for advertising or promotional purposes.

If you have any questions you may call me at (916) 327-6905.

Sincerely,

Jeffrey C. Lineberry, MPH

Chief, Retail Food Unit

Cc: Mike Boian, REHS

Northern California Technical Advisory Committee

Butte County Environmental Health

P.O. Box 5364

Chico, CA 95927

Leslie Gentry, REHS

Bay Area Technical Advisory Committee

Solano County Environmental Health

601 Texas Street

Fairfield, CA 94533

Donna Fenton

Central Valley Technical Advisory Committee

Environmental Health Services

2700 “M” Street, Suite 300

Bakersfield, CA 93301

Page 10.5

Peter Ashcraft

October 25, 2002

Elizabeth Quaranta

Southern California Technical Advisory Committee

San Diego County Environmental Health

1255 Imperial Avenue

San Diego, CA 92101

Gary Erbeck, Food Policy Committee

California Conference of Directors of Environmental Health

San Diego County Environmental Health

1255 Imperial Avenue

San Diego, CA 92101

Page 10.6

Page 10.7

Page 10.8

SBD-5863 (R. 10/00)

Evaluation #

Safety & Buildings Division

201 West Wa

shington Avenue

P.O. Box 2658

Madison, WI 53701-2658

Wisconsin

Building Products Evaluation

Material

Manufacturer

SCOPE OF EVALUATION

Section 507.2.2 of the 2003 and 2004 Supplement of the International Mechanical Code, IMC, regarding exhaust

system requirements where commercial cooking and dishwashing appliances produce grease, smoke, heat or steam have

been evaluated for compliance with certain requirements of the Wisconsin Commercial Building Code (WCBC),

Chapters Comm 61-65. Pursuant to s. Comm 61.61 the TurboChef Models Tornado (NGC), C3/C and High H (HHB)

microwave ovens are approved for use in the State of Wisconsin to satisfy the intent and the provisions of IMC 507.2.2 as

adopted by the Wisconsin Commercial Building Code.

This evaluation does not include the review for compliance to provisions of the current Wisconsin Commercial Building

Code other than those specifically referenced above.

The use of the TurboChef Models Tornado (NGC), C3/C and High H (HHB) microwave ovens are subject to the

description, limitations and conditions described in this evaluation.

DESCRIPTION AND USE

The current Wisconsin Commercial Building Code together with the 2000 edition of the International Mechanical

Code, IMC, does not specifically address, acknowledge or prohibit the utilization of recirculating hoods and vent less

steam removal systems in conjunction with commercial kitchen appliances and their operation where grease, smoke, heat

or steam is produced. The revision under the 2003 edition and 2004 Supplement of the IMC clarify the use of such

appliances.

Section 507.2.2 of the 2003 International Mechanical Code read as follows:

507.2.2 Type II hoods. Type II hoods shall be installed where cooking or dishwashing appliances produce

heat or steam and do not produce grease or smoke, such as steamers, kettles, pasta cookers and dishwashing

machines.

Microwave Oven

TurboChef Model NGC

TurboChef Technologies, Inc.

10500 Metric Dr., Suite 128

Dallas, TX 75243

200424-H Revision 2

Page 10.9

COMMERCE Product Evaluation No. 200424-H Revision 2

Page 2

Exception

:

3. A singl

e light-duty electric convection, bread, retherm or microwave oven designed for installation on a

counter or that is enclosed on five sides in a counter, provided that such appliances do not increase the

ambient temperature more than 10º F at a distance greater than 5 feet away from such appliance during

operation.

LIMITATIONS OF APPROVAL

The evaluation number assigned to this approval is to accompany each plan submitted for projects that utilizes the

TurboChef Models: Tornado (NGC), C3/C and High H (HHB) ovens.

Deviations from this approval shall void the use of the approval.

Pursuant to s. Comm 61.61(7), the department may reexamine an approval and issue a revised approval at any time.

This approval will be valid through December 31, 2009, unless manufacturing modifications are made to the product or a

re-examination is deemed necessary by the department. The product approval is applicable to projects approved under the

current edition of the applicable codes. This approval may be

void for project approvals made under future applic

able

editio

ns. The Wisconsin Building Product Evaluation number must be provided when plans that include this

product are submitted for review.

DISCLAIMER

The department is in no way endorsing or advertising this product. This approval addresses only the specified applications for the

product and does not waive any code requirement not specified in this document.

Revision Date: March 22, 2006

Approval Date: September 30, 2004 By: __________________________________

Lee E. Finley, Jr.

Product & Material Review

Integrated Services Bureau

200424-H.doc

Page 10.10

Working Together to Promote Food Safety

Minnesota Department of Health • Environmental Healt

h

Services

Sec. • P.O. Box 64975 • St. Paul, MN 55164-0975 • (651) 215-0870

Minnesota Department of Agriculture • Dairy and Food Inspection Div. • 90 W. Plato Blvd. • St. Paul, MN 55107-3219 • (651) 296-2627

An equal opportunity employer

DATE: June 11, 2004

TO: All Local Health Agencies

Minnesota Department of Health (MDH) EHS Sanitarians and Supervisors

Minnesota Department of Agriculture (MDA)

FROM: Colleen Paulus

Manager, MDH Environmental Health Services Section

Kevin Elfering

Director, MDA Meat, Food and Dairy Division

SUBJECT: Inter Agency Review Council Document 04-04V

TurboChef Tornado Oven Model NCG

Please distribute the attached information to sanitarians on your staff who work in the Food Program.

Attached please find IARC Guidance Document #04-04V regarding the new TurboChef Tornado

Microwave/Convection Oven Model NCG that is being proposed in Subway Sandwich Shops

throughout Minnesota. This document is very similar, but not exactly the same as IARC Document

#03-01 issued April 9, 2003, which addresses the TurboChef Rapid Cook Oven Model No. C3. The

emissions test for total particulate matter was much lower from the test conducted on the previous oven

(0.5mg/m

3

vs. 3.8 mg/m

3

). However, as you will note in the attached conditions for acceptance, unless

there is a sufficient amount of general ventilation existing in the space, additional cooling capacity may

be needed and verified by a certified testing and balancing contractor.

If you have any questions regarding the TurboChef Tornado Oven Model NCG use, you may

contact the Vent Committee Chair, Lorna Girard, at 651/296-1591 or at

If you have any questions regarding the IARC, please contact Sue Hibberd at 651/215-0866 or at

sue.Hibberd@health.state.mn.us

Page 10.11

S

TATE OF

M

ICHIGAN

DEPARTMENT OF AGRICULTURE

L

ANSING

JENNIFER M. GRANHOLM

GOVERNOR

DAN WYANT

DIRECTOR

April 14, 2004

Mr. James Boyd, Plan Review Specialist

Kent County Health Department

Environmental Health Division

700 Fuller Avenue, N.E.

Grand Rapids, MI 49503

Re: Turbo-Chef Convection / Microwave Oven Models C3/C and NGC

Dear Mr. Boyd:

You requested an evaluation of the Turbo Chef oven model NGC, that is proposed to be

installed in Subway restaurants state-wide. MDA recommends that both model NGC and C3/C

may be installed and used without ventilation in any food establishment as they are UL197SB

listed. These ovens contain an internal filter and vent that has been shown, under proper test

conditions, to emit very little grease (pepperoni pizzas were used in testing).

Preparation in these ovens without additional ventilation should be limited to pizzas, sub

sandwiches, reheating of par-baked or cooked foods, other similar items and baking. Neither

MDA nor the manufacturer recommends cooking raw, fatty protein products (i.e. raw meat) in

these ovens.

Michigan's mechanical code rules (R 408.30935a) specifically exempt from ventilation "listed

factory-built commercial cooking recirculating systems which are tested in accordance with UL

197" and installed per listing and manufacturer's directions. However, a mechanical inspector

may require ventilation if the building has inadequate general ventilation.

If you have any questions please call me at (517) 373-2779.

Sincerely,

Kevin Besey, Supervisor

Food Service Sanitation Section

Food and Dairy Division

cc: James Pool, Turbo Chef

Dave Adams, Assistant Chief, Mechanical Division, BCC, MDCIS

Michigan local Health Departments / MDA Regions

CONSTITUTION HALL

y

P.O. BOX 30017

y

LANSING, MICHIGAN 48909

www.michigan.gov

y

(517) 373-1104

Page 10.12

Page 10.13

Page 10.14

Page 10.15

Page 10.16

HI|IFÐtr

BiffLMHG

À!*Ð 5AfËTY

€ûÉ{tftssÍ01{,f

Rs

filÅ*sf{i\TÐ,R$w,¡l

FñËffi${T

ì/åù,¡

AldE.É\¡ELt5

VtrPëSS9E¡IIT

VICTÐ'R

H.

CUEVÀ5

HELEHAJ

UB,AT'IY

E LtlJ ûRE ll

ì¡"dlLLtALlS

James K Pool III

TurboChef Technologies

42 40 lnternational

Pa rkway

Carrollton, TX 75034

Telephone: 21 4-379-6020

Models:

NGC+, NGO

(*new

model

added),

C¡rv rF

Los ANc=r-=s

C*,LIFORFIIÅ

*NTC}NI O R VILLÀR¡.,ITÛSA

!,t.åYoR

IEFX¡*rr

B I'ILE}Ii{G ATËE}

SÂF:ETV

¡Ë.1

I{TETH

FIG{.EROÅ

STFÉET

LWAI,¡GEI-ES.

CA Ðtr

ROÊ:f RT

R.

"EUÐF

01¡.RtM

GEiEtr\¡- IS{HÂGER

RAY¡,i0t'tÐs. 0HAN,

c.E., s.Ë..

¡ts4uTir"= C!E:F.

File Number: M-100012

Effective Date:

04101 1201

I

Expiration Dafe: 04101

12012

Manufacturer: SAME

Item: WARMING OVEN

PLEASE

REFER

TO THE APPLICATION NUMBER

ON ALL

CORRESPONDENCE,

PHONE CALLS & SAMPLES

The item

processed

under the above file number

has been

tested, examined and

found to comply with

applicable

Los

Angeles Plumbin¡

Code

(LAPC)

and/or

Los Angeles

Mechanical

Code

(LAMC)

and

is

hereby approved

unless

revoked

for

cause.

This letter

or

the letterhead

copy may not be reproduced for

use in labeling

or

advertising, but copies of this letter may be

used within

your

organization and shown as evidence

ofapproval.

CONDITIONS OF APPROVAL:

1. This

product

shall

be used to warm

pre-cooked

hot

food items

only. Any other

type of cooking shall not

be allowed,

2.Installation of

this

product

is not required

to have

an exhaust system

per

Sections 95.507.1.1

and

95.507.1.2

of LAMC,

20ll Edition.

3.

This

product

shall be installed,

operated,

and

maintained

in

accordance

with

printed

instructions

from

the

manufacturer and LAMC, 2011

Edition.

Each item shall have

the

name

or trademark

of nranufacturer

and

model

numbqr'"yherc it will

be visible for inspection,

In order

to

renew

this approval,

an

application

and reexamination

fee

must be

submitted on or before

the

expiration

date shown

above.

Arrangement shall

be

made

to remove any

test samples remaining

in the

Laboratory. Samples remaining

after

21

days from

the

date of

this

notice

will

be

shipped collect by the most

convenient

carrier or

disposed of in accordance with

applicable regulation,

Jason T Tran

Mechanical

Testing Laboratory, Test Engineer

Plumbing

/ Mechanical Inspection

Inspection Bureau

Page 10.17

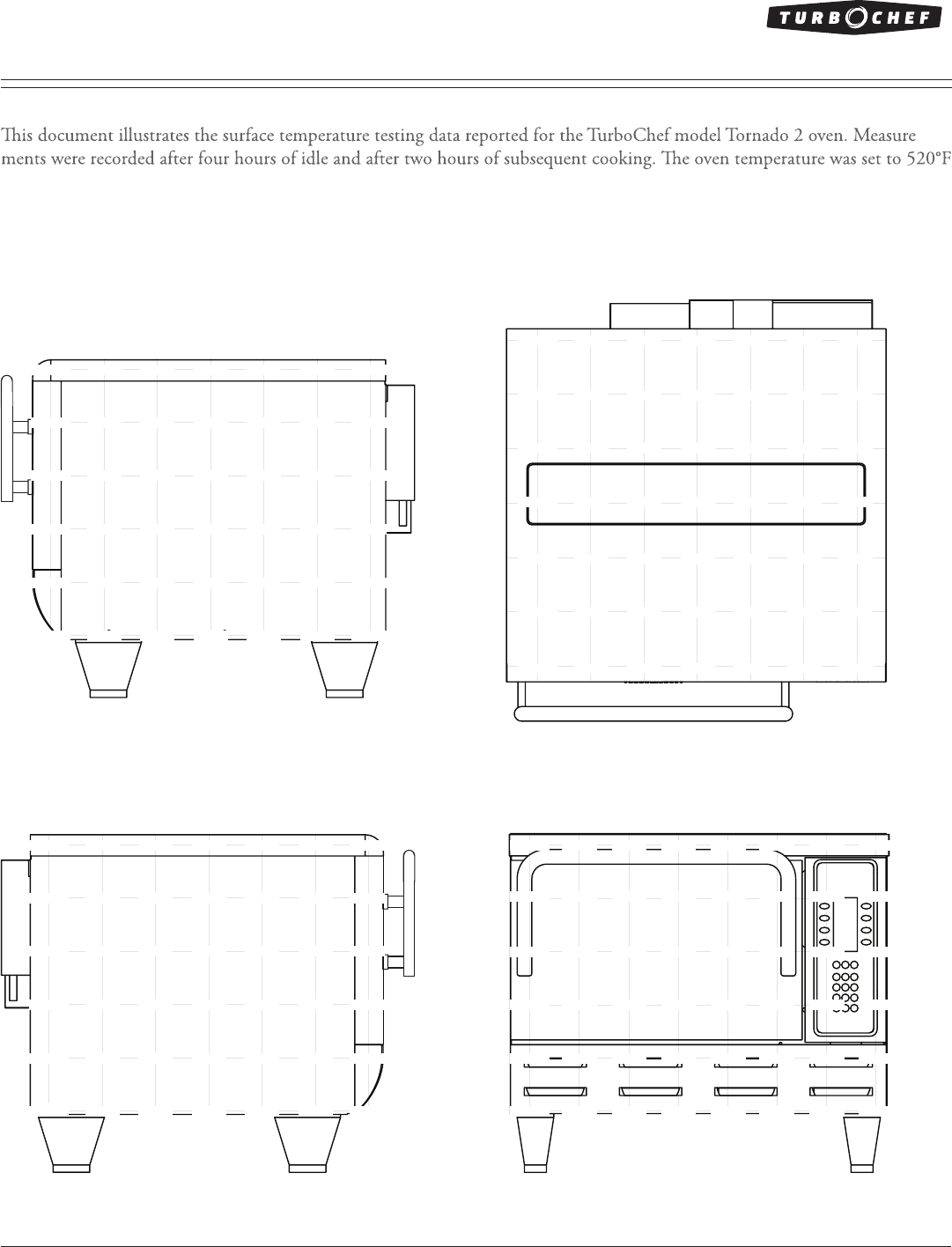

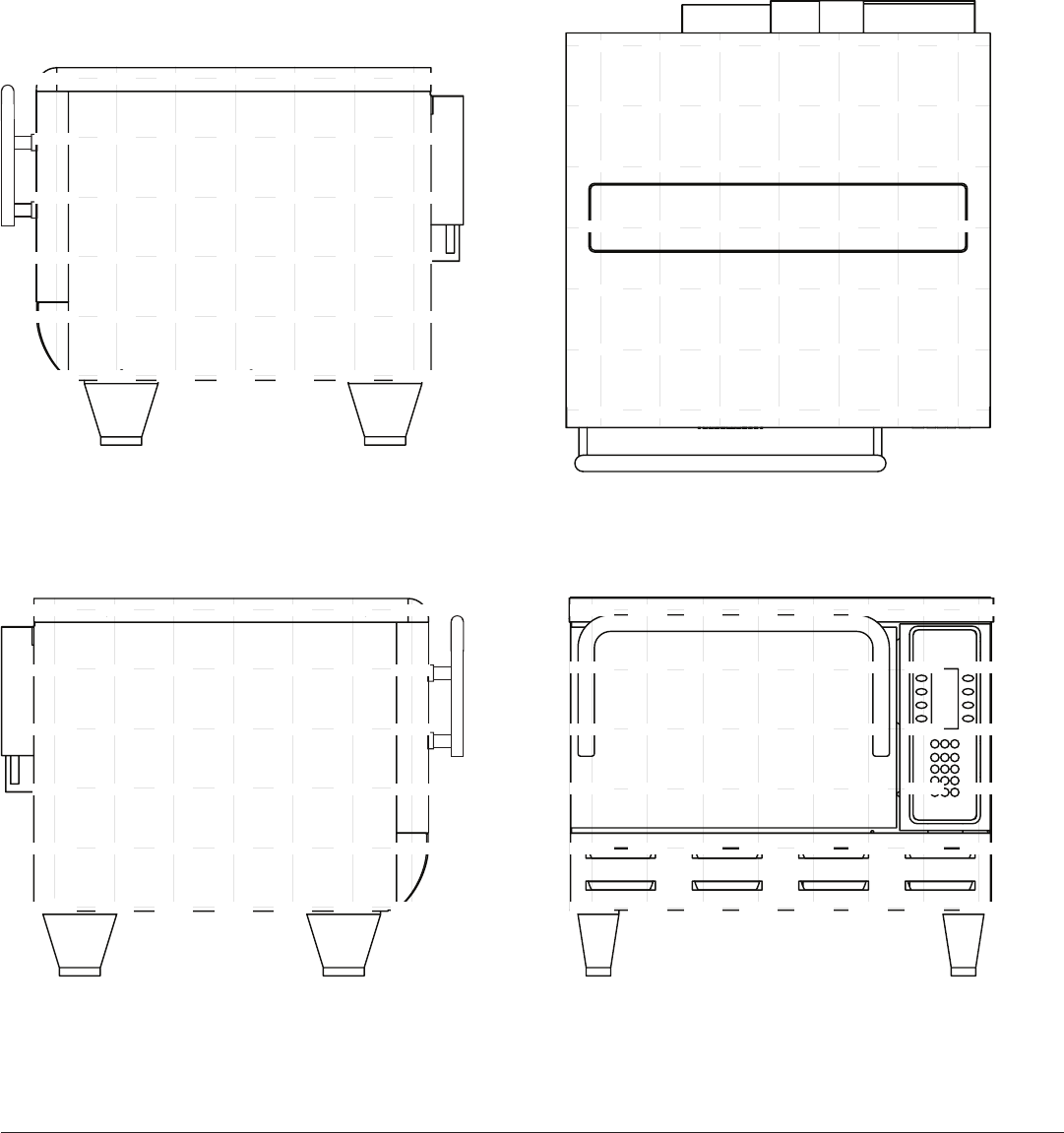

DOC-1374 / Rev B / November 2012

Page 1 of 2

© 2012 TurboChef Technologies, Inc.

TM

Tornado 2 Oven Surface Temperatures

TURBOCHE F TECH NOLOGIES, INC.

-

(271°C) for the duration of the test.

After 4-Hour Idle at 520°F/271°C (Values in °F/°C)

77/25 78/26 83/28 84/29 88/31 82/28 85/29

77/25 81/27 83/28 83/28 86/30 82/28 84/29

82/28 76/24 75/24 76/24 77/25 85/29 88/31

77/25 75/24 74/23 77/25 79/26 82/28 88/31

78/26 78/26 79/26 82/28 82/28 81/27 78/26

81/27 78/26 81/27 83/28 77/25 75/24 78/26

83/28 91/33 102/39 94/34 86/30 92/33 82/28

87/31 85/29 90/32 89/32 87/31 86/30 86/30

79/26 80/27 72/22 71/22 71/22 84/29 83/28

81/27 80/27 80/27 81/27 75/24 77/25 99/37

84/29 82/28 86/30 88/31 83/28 76/24 93/34

84/29 85/29 93/34 89/32 86/30 84/29 83/28

93/34 99/37 99/37 95/35

90/32

79/26 80/27 79/26

97/36 98/37 98/37 97/36

97/36

83/28 95/35 80/27

91/33 95/35 96/36 97/36

97/36

83/28 83/28 83/28

82/28 89/32 95/35 96/36

91/33

80/27 79/26 78/26

78/26 81/27 82/28 87/31

78/26

75/24 75/24 76/24

87/31 91/33 91/33 94/34

93/34

88/31 81/27 76/24

84/29 89/32 111/44 108/42 100/38 80/27 80/27

94/34 96/36 98/37 102/39 99/37 92/33 86/30

83/28 84/29 91/33 103/39 98/37 96/36 93/34

83/28 109/43 133/56 138/59 118/48 92/33 90/32

82/28 123/ 146/ 148/ 130/ 90/32 81/27

83/28 125/52 142/61 149/65 128/53 83/28 80/27

88/31 92/33 95/35 92/33 90/32 88/31 83/28

Page 11.1

DOC-1374 / Rev B / November 2012

Page 2 of 2

© 2012 TurboChef Technologies, Inc.

After 4-Hour Idle and 2 Hours of Cooking at 520°F/271°C (Values in °F/°C)

92/33 131/55 120/49 110/43 111/44 107/42 102/39

87/31 101/38 110/43 103/39 101/38 100/38 102/39

100/38 93/34 92/33 97/36 100/38 102/39 101/38

103/39 95/35 93/34 102/39 106/41 102/39 99/37

109/43 106/41 105/41 113/45 110/43 93/34 94/34

123/51 113/45 109/43 119/48 102/39 88/31 99/37

95/35 103/39 111/44 107/42 100/38 105/41 95/35

93/34 99/37 101/38 103/39 102/39 102/39 100/38

91/33 92/33 88/31 88/31 87/31 99/37 97/36

93/34 93/34 93/34 97/36 88/31 87/31 106/41

96/36 96/36 101/38 102/39 96/36 88/31 104/40

95/35 97/36 104/40 103/39 97/36 96/36 95/35

98/37 105/41 108/42 106/41

101/38

111/44 106/41 105/41

104/40 103/39 105/41 108/42

109/43

120/49 118/48 111/44

98/37 103/39 109/43 110/43

109/43

125/52 114/46 121/49

90/32 103/39 112/44 113/45

106/41

106/41 103/39 104/40

90/32 93/34 96/36 100/38

88/31

90/32 90/32 92/33

97/36 100/38 100/38 104/40

105/41

98/37 93/34 86/30

90/32 94/34 118/48 114/46 122/50 112/44 97/36

99/37 106/41 111/44 118/48 126/52 111/44 98/37

90/32 90/32 97/36 114/46 106/41 107/42 106/41

91/33 114/46 135/57 142/61 132/56 110/43 103/39

91/33 130/54 154/68 163/73 148/64 118/48 100/38

89/32 124/51 154/68 162/72 144/62 112/44 102/39

97/36 104/40 108/42 110/43 114/46 110/43 102/39

Page 11.2

©2017 TurboChef Technologies, Inc.

DOC-1448 / Revision C / January 2017

TM

Installation Recommendations

TURBOCHEF TECHNOLOGIES, INC.

Page 12.1

Oven Voltage Current Phase

Soˇta (i1) 208/240 VAC 30 amp 1 Ph

Soˇta Single Mag (i1) 208/240 VAC 20 amp 1 Ph

i3 208/240 VAC

208/240 VAC

40 amp

30 amp

1 Ph

3 Ph

i5 208/240 VAC

208/240 VAC

50 amp

30 amp

1 Ph

3 Ph

Encore/Encore 2 208/240 VAC 30 amp 1 Ph

Tornado 208/240 VAC 30 amp 1 Ph

C3 208/240 VAC 50 amp 1 Ph

HhC 2620 208/240 VAC 50 amp 3 Ph

HhC 2020 208/240 VAC 50 amp 3 Ph

HhC 1618 208/240 VAC

208/240 VAC

30 amp

50 amp

3 Ph

1 Ph

HhB 2 208/240 VAC 30 amp 1 Ph

Double Batch 208/240 VAC

208/240 VAC

50 amp

30 amp

1 Ph

3 Ph

Waterless Steamer (i1) 208/240 VAC 30 amp 1 Ph

Panini (i1) 208/240 VAC 30 amp 1 Ph

Fire 208/240 VAC 30 amp 1 Ph

Bullet 208/240 VAC 30 amp 1 Ph

Menu Requirements

TurboChef ovens have been approved by Underwriter’s

Laboratory for ventless operation (UL KNLZ listing) for

all food items EXCEPT for foods classied as “fatty raw

proteins.” Such foods include bone-in, skin-on chicken, raw

hamburger meat, raw bacon, raw sausage, steaks, etc.

e TurboChef certication includes precooked food items

such as pizza toppings, sandwich meats, frozen appetizers,

and cheeses. Additionally, raw, lean meats such as boneless,

skinless chicken breasts and sh fall within the certication.

Cleaning Requirements

To ensure continued compliance with all health, building,

and re codes, users are required to:

oUse only TurboChef-approved cleaning chemicals.

oFollow monthly and quarterly cleaning instructions

provided in the manual. Post cleaning instructions near

the oven.

oVentless installation requires that the areas around

the oven (walls, ceilings, kitchen equipment, etc.)

be cleaned as needed but no less than once every

other month.

Installation Near Open Heat Source

When placing a TurboChef oven near an open heat source

(see illustration below), strictly adhere to the following:

• If the oven is being placed near a grill or stove, a divider

must exist between the oven and the open heat source,

with a minimum of 6” (152 mm) between the oven and

the divider.

• If the oven is being placed near a fryer, a divider must

exist between the oven and fryer, with a minimum of 12”

(305 mm) between the oven and the divider.

• e height of the divider must be greater than or equal

to the height of the oven.

Grill

Partition

Height Equal to

Oven Height

Oven

6”

(152 mm)

Minimum

12”

(305 mm)

Minimum

Deep Fryer

Counter Top / Table

Partition

INLET AIR

E

X

H

A

U

S

T

E

X

H

A

U

S

T

Height Equal to

Oven Height

TurboChef ventless ovens have internal systems for destroying

grease laden vapor prior to the grease escaping the oven; therefore,

the ovens are certied as non-grease emitting appliances. When

following our recommendations, TurboChef ovens can be installed

without the aid of a Type I or Type II hood per International

Mechanical Code (2006, 2009, and 2012), NFPA 96, NFPA 101

(Life Safety Code), EPA 202, and Underwriter’s Laboratory

(UL KNLZ).

e following guide is intended to give relevant information for

the ventless installation, operation, and maintenance of TurboChef

ovens. It is important that these guidelines are followed and that

the oven and surrounding areas be maintained regularly for

optimal performance.

Certications

Safety – UL, TUV (CE)

Sanitation – NSF

*

, UL EPH

*

Ventless – UL (KNLZ)

Electrical Requirements

TurboChef ovens must be installed on a circuit equal to the ratings

listed below, per NEC sec 210.23, permissable loads.

* NSF certication applies to the Tornado, C3, and HhB 2 ovens only. UL EPH certication applies to all

ovens except the C3.

Ventilation

TurboChef ovens must be installed in a well-ventilated space.

e space should have an exhaust rate of .70 cfm per square

foot of kitchen space and an additional 100 sq. ft. (9.3 m

2

)

of virtual space per ventless cooking appliance (TurboChef or

any other).

If the air inlet is for general exhaust, pursuant to requirements

for 507.2.2, paragraph 2, locate the air inlet above the center

point of each oven.

e heat load from TurboChef ovens is mostly sensible. e

only latent heat present is due to evaporation during the

cooking process. When installing a TurboChef oven, the

space must have the following tons of AC per oven installed.

Oven Tons of AC

Soˇta (i1) 0.29

Soˇta Single Mag (i1) 0.29

i3 0.94

i5 1.31

Encore/Encore 2 0.45

Tornado 0.58

C3 0.63

HhC 2620 1.82

HhC 2020 1.47

HhC 1618 1.00

HhB 2 0.84

Double Batch 1.04

Waterless Steamer (i1) 0.29

Panini (i1) 0.29

Fire 0.50

Bullet 0.13

©2017 TurboChef Technologies, Inc. Page 12.2

TM

Oven Clearances

Verify the oven location has the following clearances on

the top and each side. TurboChef ovens have built-in back

bumpers that allow for the necessary spacing from the oven to

the back wall.

Oven Top Sides

Soˇta / Soˇ ta Single Mag (i1) 5” (127 mm) 2” (51 mm)

i3 19” (483 mm) 2” (51 mm)

i5 19” (483 mm) 2” (51 mm)

Encore/Encore 2 5” (127 mm) 2” (51 mm)

Tornado 4” (102 mm) 2” (51 mm)

C3 4” (102 mm) 2” (51 mm)

HhC 2620 10” (254 mm) 0” (0 mm)

HhC 2020 10” (254 mm) 0” (0 mm)

HhC 1618 10” (254 mm) 0” (0 mm)

HhB 2 2” (51 mm) 2” (51 mm)

Double Batch 2” (51 mm) 2” (51 mm)

Waterless Steamer (i1) 5” (127 mm) 2” (51 mm)

Panini (i1) 5” (127 mm) 2” (51 mm)

Fire 2” (51 mm) 2” (51 mm)

Bullet 5” (127 mm) 2” (51 mm)

How the Ovens are Tested

TurboChef ovens are evaluated according to UL. e

evaluation entails placing the test oven in an environmental

chamber built to capture all emissions escaping during

idle, cooking, and door-open conditions. During the

eight-hour test period, a typical worst-case food item is

cooked continuously, and 100% of condensable and non-

condensable emissions from the product are collected and

analyzed according to the EPA 202 Test Method. At the

conclusion of the test, the total concentration of particulate

matter (emissions) must be less than 5.0 mg/m

3

for the

oven to be certied for ventless operation. Cooking devices

that measure above the 5.0 mg/m

3

threshold are considered

to produce grease and must be installed under Type I

ventilation, according to International Mechanical Code.

TurboChef ovens are well below the 5.0 mg/m

3

threshold as

shown below.

NOTE: Certain congurations of TurboChef ovens, such as

a triple stacked HhC 2620, may cause emissions to be greater

than 5.0 mg/m

3

. In these situations, TurboChef recommends

that the ovens be installed under a Type I or Type II hood.

Contact Information

For questions regarding a ventless installation, email

[email protected]. For questions or concerns

regarding an existing installation, contact Customer Service

at 1.800.908.8726, Option 1.

Ventless Requirement 5 5 5 5 5 5 5 5 5 5 5 5

Emissions 1.35 0.4 2.8 0.32 0.21 0.64 0.13 1.12 1.91 2.4 0.48 0.13

C3 HhB I5 I3 Tornado Sota Encore HhC

2020

HhC

2620

Fire BulletHhC

1618

0

1

2

3

4

5

6

Emissions

mg/m

3

5

1.04

Double

Batch