OWNER’S MANUAL

Table of Contents

Certications & Specications ....................... 7

Manufacturer’s Certications ...................................................................7

Manufacturer’s Specications .................................................................9

Introduction ................................................... 11

Warranty & Construction Standards ...................................................... 11

Specic Data ......................................................................................... 11

Education .............................................................................................. 11

Owner/Operator Responsibilities...........................................................12

Nautical Terms .......................................................................................13

Safety ............................................................ 17

Explanation of Safety Precautions ......................................................17

Fire ........................................................................................................18

Fire Suppression Equipment ................................................................. 19

Flooding, Swamping ..............................................................................19

Lifesaving Equipment ............................................................................ 20

Impaired Operation................................................................................21

Carbon Monoxide Poisoning ................................................................21

Information ............................................................................................24

Load Capacity .......................................................................................25

Power Capacity .....................................................................................25

Stability ..................................................................................................25

Warning Labels .....................................................................................26

Weather ................................................................................................. 28

Accident Report .....................................................................................28

Hotlines .................................................................................................28

Minimum Required Equipment .............................................................. 29

Additional Recommended Equipment .................................................. 30

Barletta Floorplan Occupant Positions - L Class ................................... 31

Barletta Floorplan Occupant Positions - E Class ..................................33

Barletta Floorplan Occupant Positions - C Class ..................................35

Navigation ...................................................... 37

Rules of the Road..................................................................................37

Basic Rules ...........................................................................................38

Boat Navigation Lights ..........................................................................39

Charts & Aids to Navigation...................................................................41

Environmental Considerations ..................... 43

Fuel & Oil Spillage .................................................................................43

Waste Disposal .....................................................................................43

Garbage Discharge Restrictions ..........................................................44

Excessive Noise .................................................................................... 45

Wake/Wash ...........................................................................................45

Exhaust Emissions ................................................................................ 45

Paint, Cleaning Agents & Other Substances .........................................46

Emergency Procedures ................................. 49

Explosion & Fire ....................................................................................49

Flooding, Swamping or Capsizing ........................................................51

Collision .................................................................................................51

Grounding..............................................................................................51

Leaks .....................................................................................................51

Towing ...................................................................................................52

Person Overboard ................................................................................. 53

Drowning ...............................................................................................53

Medical Emergency ...............................................................................53

Carbon Monoxide .................................................................................. 54

Propulsion, Control or Steering Failure .................................................54

Radio Communication .......................................................................... 54

Distress Signals.....................................................................................55

Operational Inspection .................................. 57

Before Departure ...................................................................................57

After Return ........................................................................................... 58

Operation ....................................................... 59

Fueling...................................................................................................59

General..................................................................................................60

Boarding (Wear a PFD!) ........................................................................ 61

Reboarding - Unassisted .......................................................................62

Starting, Stopping ..................................................................................62

Shifting ..................................................................................................64

Casting O ............................................................................................64

Approaching Dock ................................................................................. 65

Handling Dock Lines .............................................................................68

Anchoring ..............................................................................................69

Maneuvering/Maintaining Control..........................................................72

Operating In Shallow Water ..................................................................76

Water Skiing, Swimming & Diving .........................................................77

Version 8.20 August 2020

Maintenance .................................................. 81

Service Schedule ..................................................................................81

Maintenance Log ..................................................................................81

Maintaining Hull & Deck .......................................................................82

Housekeeping .......................................................................................84

Lifting .....................................................................................................85

Winterizing/Storing ................................................................................85

Recommissioning .................................................................................. 87

Troubleshooting .....................................................................................88

Systems.......................................................... 91

Trailering ...................................................... 107

Table of Contents

Certications & Specications ....................... 7

Manufacturer’s Certications ...................................................................7

Manufacturer’s Specications .................................................................9

Introduction ................................................... 11

Warranty & Construction Standards ...................................................... 11

Specic Data ......................................................................................... 11

Education .............................................................................................. 11

Owner/Operator Responsibilities...........................................................12

Nautical Terms .......................................................................................13

Safety ............................................................ 17

Explanation of Safety Precautions ......................................................17

Fire ........................................................................................................18

Fire Suppression Equipment ................................................................. 19

Flooding, Swamping ..............................................................................19

Lifesaving Equipment ............................................................................ 20

Impaired Operation................................................................................21

Carbon Monoxide Poisoning ................................................................21

Information ............................................................................................24

Load Capacity .......................................................................................25

Power Capacity .....................................................................................25

Stability ..................................................................................................25

Warning Labels .....................................................................................26

Weather ................................................................................................. 28

Accident Report .....................................................................................28

Hotlines .................................................................................................28

Minimum Required Equipment .............................................................. 29

Additional Recommended Equipment .................................................. 30

Barletta Floorplan - Occupant Positions ................................................31

Navigation ...................................................... 37

Rules of the Road..................................................................................33

Basic Rules ...........................................................................................34

Boat Navigation Lights ..........................................................................35

Charts & Aids to Navigation...................................................................37

Environmental Considerations ..................... 39

Fuel & Oil Spillage .................................................................................39

Waste Disposal .....................................................................................39

Garbage Discharge Restrictions ..........................................................40

Specications & Intro - 7

Certications &

Specications

Manufacturer’s Certications

A “CE Mark” means that the boat complies with all applicable European

direc tives for recreational boats. International Organization for Standardization

(ISO) standards are widely used within the certication process.

“NMMA Certication” means that the boat has been determined by the National

Marine Manufacturers Association to be in compliance with appli cable United

States Federal Regulations and American Boat and Yacht Council (ABYC)

Standards.

The following information is furnished in compliance with European direc tives

(Recreational Craft Directive, RCD) and Recreational Craft Sectoral Group

(RSG) Guidelines in eect as of the date of publication of this manual. The boat

manufacturer will provide additional information if standards are amended.

Manufacturer

Name _____________________________________________

Address ___________________________________________

City, State, Country __________________________________

Hull Identication Number (HIN) ___________________________

Engine Serial Number ___________________________________

Model Name ___________________________________________

Boat Type:

q Non-powered q Power Inboard q Sail

q Power Outboard q Power Multi-hull q Sail Multi-hull

Design Category:

q Ocean q Inshore

q Oshore q Sheltered Waters

Denition of the relevant design category(ies)

__________________________________________________________

__________________________________________________________

Barletta Boat Company, LLC

51687 County Road 133

Bristol, IN USA

8 - Specications & Intro

Length of hull - meters (feet) __________________________________

Beam of hull - meters (feet) ___________________________________

Maximum Rated Engine Power - kilowatts (horsepower) _____________

Mass of boat for trailering _____________________________________

Unladen Weight - kilograms (pounds) ___________________________

Maximum Load recommended - kilograms (pounds) ________________

Maximum Number of Persons Recommended ____________________

Conformity to Standards listed as follows: ________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

Specications & Intro - 9

Manufacturer’s Specications

ISO 10240 requires specic information to be provided. ABYC Technical

Information Report T-24 recommends additional data be provided. The following

may be included in an owner’s packet supplied with the boat.

• Warranty Terms and Conditions

• Hull Identication Number

• Engine/Outdrive Serial Numbers

• Type of Boat/Series Name

• Dimensions - meters (feet):

- Length

- Beam

- Vertical Clearance

- Draft

• General Arrangements:

- Deck Plan

- Interior Plan

- Prole

• Sail and Rigging Plan

• Propulsion:

- Engine Type

- Engine Layout

- Propeller

- Shafting

- Instructions on the safe operation

of the engine(s) and generator

• Electrical:

- Information on re or explosion

hazards

- Rated Amperage

- Voltages, Frequency, Phases

- Battery Capacity

- Switches, Fuses, Circuit

Breakers (location, type)

- Description of Switch Panels

• Lightning Protection System

• Tank Capacities - liters (gallons):

- Fuel

- Fresh Water

- Waste Holding Tanks

- Gas Cylinders (LPG) and

Information on the safe operation

of gas (LPG) appliances

- Information on the useable

capacity of tanks depending on

boat trim and loading

• System Diagrams:

- Potable Water

- Gray Water

- Black Water (Waste)

- Information on all water

systems including the location

of through hull and deck ttings

and the draining point. Also,

use of a Y-valve and pump-out

procedures for holding tanks.

- Exhaust

- Ventilation

- Bilge Pump(s)

- Steering

- Engine Cooling

• Openings in the Hull:

- Location of seacocks and

through hull openings

- Advice on keeping hull openings

closed or open as appropriate, to

minimize the risk of ooding.

- Advice on keeping other

openings closed when

appropriate, e.g. in rough water.

10 - Specications & Intro

• Instrument Use & Calibration

• Stability and Buoyancy and

Flotation Capability and

Explanation

• Strong Points for Docking, Lifting,

Trailering

• Safety Labels, Part Numbers, and

Ordering Procedure

• Bilge Pumps:

- Advice that the bilge pump is not

for damage control

- Location of each pump and its

capacity

- Operating Instructions

- Advice to check function at

regular intervals

• Fire Protection Equipment:

- Instructions on the location and

use of the re ghting equipment

- Identication and location

- of means of escape from the

interior in case of re

• Recommended Spare Parts

• Standard Equipment

• Optional Equipment

• Reference Manuals for Other

Equipment

• Contacting Manufacturers of

Other Systems

• Contacting Factory Service

Department

• Construction Features

• Construction Standards

Specications & Intro - 11

Section I

Introduction

This manual has been compiled to help you operate your craft with safety and

pleasure. It contains details of the craft, typical equipment supplied or tted, its

systems and information on its operation and maintenance. Please read this

manual carefully, and familiarize yourself with the craft before using it.

If this is your rst boat, or if you are changing to a type of boat that is unfa miliar

to you, for your own safety and comfort, please ensure that you obtain handling

and operating instruction/experience before “assuming command” of your boat.

Your dealer, local yacht club, local Coast Guard Auxiliary, or the US Coast Guard

oce will be pleased to assist you in nding sources of instruction.

Please keep this manual in a secure place, and hand it over to the new

owner when you sell the craft.

Warranty & Construction Standards

Your boat manufacturer may provide a Warranty Statement describing terms

and conditions under which defects in your boat will be repaired. Familiarize

yourself with the warranty and follow instructions regarding proper operation and

maintenance. Lack of attention to instructions can void the warranty.

A copy of the factory warranty for the boat is included with the documents you

received when the boat was delivered.

The manufacturer may also provide a Construction Standards Statement

detailing industry standards followed in building your boat. Consult your marine

dealer for additional information.

Specic Data

You must know specic data about your boat’s capabilities and requirements.

This information is available from the manufacturer and/or your dealer. See the

Manufacturer’s Certications & Specications sections in the front of this manual

for specic data that you should expect to have provided.

The owner’s manuals for equipment installed on or associated with your boat

is included with the documents you received when the boat was delivered.

Before operating equipment, particularly the engine, read the owner’s manual

accompanying the equipment.

Education

Learn how to operate your boat safely!!!!! This manual is not intended to teach

you everything you need to know about the operation of your boat. It is strongly

recommended that you receive training in proper boat handling and navigation

before using your boat.

12 - Specications & Intro

Some agencies which oer boating courses are:

• Coast Guard Auxiliary

• United States Power Squadrons

• Canadian Power and Sail Squadrons

• Red Cross

• State Boating Oces

• Yacht Clubs

Ask your marine dealer or check local listings for agencies near you. Information

is also available from the BoatUS Foundation by calling 1.800.368.5647, or you

can go to the Internet to check for boating courses.

www.boatus.com

www.boatsafe.com

www.uscgboating.org

www.boat-ed.com

www.nationalsafeboatingcouncil.org

For international information, consult your dealer.

Owner/Operator Responsibilities

The law requires the owner/operator to assist any person or boat in dis tress as

long as he does not endanger his boat. The owner/operator is also responsible

for understanding and complying with the following regulations, procedures and

operational requirements:

• Registration - Register your boat in the area where it is used most

frequently. Many areas require additional registration when an out-of

area boat is used within their boundaries. Contact boating authorities or

your marine dealer for registration requirements and forms.

• Insurance required, liability and hull coverage.

• Manufacturer’s warranty registration, procedures, terms and conditions.

• Safety equipment.

• Maintenance and safe conduct of the vessel and its systems.

• Safety and safety training of the passengers and crew.

• Rules of the Road for navigation and boat handling.

• Knowledge of boating safety courses.

• Knowledge of boat systems and capabilities/limitations of the boat.

• Break-in procedure.

• Seaworthiness and operational inspection of the boat.

• Safe operating practices and avoidance of product misuse.

• Avoiding use of alcohol or drugs while boating.

• Knowledge of federal, state, and/or local environmental regulations.

• Knowledge of accident reporting requirements (See USCG Accident

Report form).

Specications & Intro - 13

Nautical Terms

Abeam Object 90 degrees to center line on either side of boat.

Abaft A point on a boat that is aft of another, or toward or at the

stern of the boat.

Aft Toward the rear or stern of the boat.

Beam The width of a boat.

Bow The forward part of a boat.

Bulkhead Vertical partition in a boat.

Chine Meeting juncture of side and bottom of boat.

Chock Deck tting, used as guide for mooring or anchor lines. Also

a wedge to stop wheels from rolling.

Cleat A deck tting with arms or horns on which lines may be

secured for mooring. (Mooring cleats are not for towing or

being towed.)

Cockpit An open space from which a boat is operated.

Deck Upper structure which covers the hull between gunwales.

Draft Depth of water required to oat the boat and its propul sion

system.

Fathom Six feet.

Fenders Rope, plastic, wood, or rubber pieces hung over the side to

protect the hull from chang.

Freeboard The minimum distance from the waterline to the top edge of

the side of the boat.

Ground Tackle General term referring to anchors, anchor lines, etc.

Gunwale (Pronounced as gunnel} The top edge of the side of the

boat.

Hatch An opening in deck to provide access below.

Head Toilet or toilet area in a boat.

Headroom Vertical distance between the deck and cabin or cano py

top.

Helm Steering console.

Hull The basic part of a boat that provides buoyancy to oat the

weight of the vessel and its load.

Keel The major longitudinal member of a hull; the lowest external

portion of a boat.

Knot Unit of speed in nautical miles per hour. 1 knot= 1.15 MPH

Lee The side that is sheltered from the wind.

14 - Specications & Intro

PFD Personal otation device; life preserver.

Port A term designating the left side of the boat when fac ing

forward.

Rudder Movable xture at the stern used for steering.

Scupper Hole permitting water to drain overboard from deck or

cockpit.

Sheer Curve or sweep of the deck as viewed from the side.

Snub To check or tighten a line suddenly.

Starboard A term designating the right side of the boat when facing

forward.

Stem Eye Bolt with looped head mounted on extreme forward part of

bow.

Stern The aft end of a boat.

Transom The main member of the boat structure at the stern of the

boat extending from deck to keel.

Wake Disturbed water that a boat leaves behind as a result of

forward motion.

Windward Toward the direction from which the wind is blowing.

Specications & Intro - 15

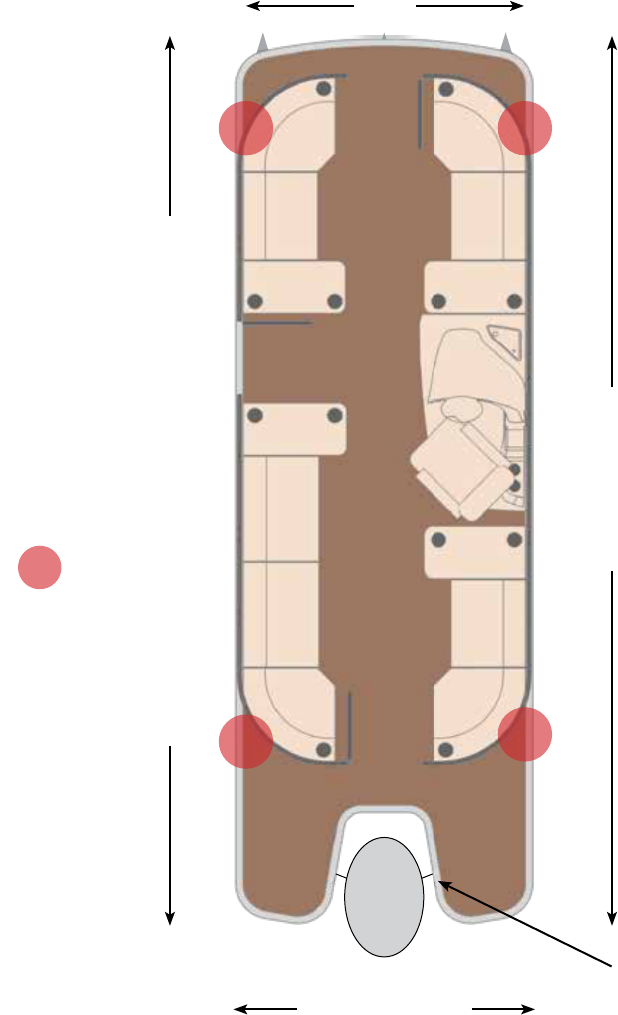

LENGTH OVERALL

BOW

STERN

AFT FORWARD

DECK

COCKPIT

HELM

ENGINE

PORT

STARBOARD

BEAM

HIN (HULL

INDENTIFICATION

NUMBER) IS STAMPED

ONTO THE TRANSOM

TRANSOM

= STRONG POINT

16 - Specications & Intro

Safety - 17

Section I

Safety

The freedom of boating is a magnicent feeling. However, fun can be over taken

by disaster if you ignore safety precautions. This book presents basic guidelines,

but it cannot describe every possible risk you may encounter. You are strongly

urged to:

• Take a boating safety course and get hands-on training from your

boat dealer.

• Regularly review safety requirements.

• Maintain your boat and its systems.

• Have your boat inspected at least annually by a qualied

mechanic or dealer.

Explanation of Safety Precautions

This manual contains safety precautions which must be observed when operating

or servicing your boat. Review and understand these instructions and warnings.

Labels are used to alert the boater to potential hazards. Each label will contain all

four of the following messages:

1. Signal Word; Danger, Warning or Caution.

2. The nature of the hazard.

!

DANGER

Indicates an imminently hazardous situation, that if not avoided, WILL result

in death or serious injury. Limited to the most extreme situations. Red, if

color is used.

CAUTION

!

Indicates a potentially hazardous situation that, if not avoided, MAY result in

minor or moderate injury or property damage. It may also be used to alert

against unsafe practices. Yellow, if color is used.

NOTICE

Information that is important to proper operation or maintenance, but is not

hazard-related. Any color can be used.

Indicates a potentially hazardous situation that, if not avoided, COULD result

in death or serious injury. Orange, if color is used.

WARNING

!

18 - Safety

3. The consequences that can result if the instructions to avoid the

hazard are not followed.

4. Message panel - Instructions on how to avoid the hazard.

Fire

Fire is always serious, but it usually can be brought under control if you

are prepared and act quickly. Extinguishers required by the Coast Guard

or other boating law enforcement agencies are only the minimum needed.

Install re extinguishers where they might be needed, and test equipment

and emergency plans regularly.

Prevention is the safest method of ghting re. Remember:

• Use extreme caution and do not smoke while fueling.

• Extinguish smoking material carefully.

• Keep hatches and hull/cabin openings shut while fueling.

• Keep blowers o while fueling.

• Use the “sni test” to check for fumes in the bilge and engine

compartment after fueling and at regular intervals.

• Remove canvas before starting engine.

• Run exhaust blowers at least 4 minutes before starting engine(s).

• Ensure that ventilation systems are clear and not obstructed.

• Use only marine safety approved cooking and heating systems.

• Open ames demand constant attention.

• Be extremely careful when using liquied petroleum gas (LPG) or

compressed natural gas (CNG).

• Close valves to LPG/CNG cylinders and supply lines when not in

use.

• Ensure fuel does not leak. Regularly inspect all fuel systems

including LPG/CNG.

• Store ammable material in safety-approved containers.

• Keep ammable material containers in a locker sealed from the

boat interior and vented overboard.

• Use special care with ames or high temperatures near urethane

foam, if used.

• Check cleaning products for ammability.

• Ventilate when cleaning or painting.

• Disconnect electrical system from its power source before

performing maintenance. (See Systems - Electrical.)

• Replace breaker or fuse with same amperage device.

• Electrical appliances must be within rated amperage of boat

circuits.

• Observe the boat carefully while the electrical system is

energized.

• Only a qualied marine electrical technician may service the

boat’s electrical system.

1 2 3 4 5 6

8 9 10 11 12 13

15 16 17 18 19 20

12 23 24 25 26 27

29 30 31 32 33 34

7

14

21

28

35

Safety - 19

Fire Suppression Equipment

General

• Fire suppression equipment can be either xed or portable.

Fixed systems are located in the machinery compartments. They

should be supplemented by portable extinguishers mounted at

key sites, for example, near the engine compartment, galley and

helm.

• Coast Guard or other boating law enforcement agency

regulations govern the number and type of devices on board.

(See Safety - Minimum Required Equipment.)

Fixed System

• An automatic re extinguishing system may be installed

permanently in one or more machinery spaces. In the event of

a re, the system releases re-extinguishing material into the

compartment.

• Fixed system is wired to the ignition and turns on with the engine.

• An indicator light on the helm is lit when the re suppression

system is available. The light goes out when the system

discharges.

Portable Extinguishers

Fire extinguishers are classied according to re type:

• “A” - Combustible solids (wood, plastic)

• “B” - Flammable liquids (oil, gasoline)

• “C” - Electrical res

Sizes are identied by Roman numerals - from I (smallest) to V (largest). Small

size provides only a few seconds of reghting capability.

Flooding, Swamping

Flooding or swamping can be caused by many factors. Operator disregard for

hazardous weather and water conditions is one of the most common causes,

along with improper loading, handling and anchoring. Be aware of the possible

consequences of your actions. Have everyone wear a personal otation device

when boating. STAY WITH THE BOAT!

Remember:

• Certication Label states maximum weight/number of persons the

boat will handle safely under normal conditions. Give yourself an

extra margin in rough water. (See Safety - Load Capacity.)

• Install drain plugs before launching.

• Ensure proper bilge pump operation.

• Anchor from bow if using only one anchor.

• Match speed to sea conditions.

• Adjust trim and close openings in rough weather.

20 - Safety

• Reverse engine only when headway slows to prevent following

sea from swamping boat.

• Operate boat within maneuvering speed limitations.

Lifesaving Equipment

Wear a personal otation device (PFD) when boating. Boat operators are

required to carry one wearable personal otation device (fype I, 11, Ill or

V) for every person on board. Boats must also have at least one throw able

device (f ype IV). Classications of PFDs are:

• O-Shore Life Jacket (type I) - most buoyant, it is designed to

turn an unconscious person face up; used in all types of waters

where rescue may be slow.

• Near-Shore Life Vest (type II) - “keyhole” vest with otation-lled

head and neck support is also designed to turn a person face up,

but the turning action is not as pronounced; used in calm, inland

waters or where quick rescue is likely.

• Flotation Aid (type Ill) - vest is designed so conscious wearers

can turn face up; often designed for comfort while engaged in

sports such as skiing.

• Throwable Devices (type IV) - horseshoe buoys, ring buoys,

and buoyant cushions are designed to be grasped, not worn.

• Special-Use Devices (type V) - sailboat harnesses, white-water

vests, oat coats, and hybrid vests.

When purchasing PFDs look for a tag that says they are approved by the U.S.

Coast Guard and there should be an approval number on the tag. PFDs come in

dierent shapes, colors, and materials, and they are designed for dierent uses.

Choose your PFD with your planned activities and water conditions in mind. Also,

be sure you understand the require ments and regulations of the state or region in

which you are boating.

Children and non-swimmers must wear PFDs at all times when aboard. All

passengers and crew should wear them, since an unworn PFD is often useless

in an emergency. The law requires that PFDs, if not worn, must be readily

accessible, that is, removed from storage bags and unbuckled. Throwable

devices must be readily available, that is, right at hand. The operator is

responsible for instructing everyone on their location and use.

Size PFDs for the wearer. Children require special attention. Check state boating

law regulation for child PFD wear requirements.

PFDs require regular maintenance and service. Always dry your PFD before

storage. Take your PFD to your dealer or call the manufacturer for other

instructions about service and maintenance.

Test PFD buoyancy at least once a year.

Safety - 21

Impaired Operation

Give special attention to the eects of alcohol and drugs while boating.

No other single factor causes so many marine accidents and deaths.

Wind, waves and sun, heighten the eects of alcohol and drugs, so your

reactions may be quickly impaired.

Carbon Monoxide Poisoning

Each year, boaters are injured or killed by carbon monoxide. Most poison-

ings occur on older boats and within the cabin or other enclosed areas. Virtually

all of them are preventable.

Carbon monoxide is a potentially deadly gas produced any time a carbon-

based fuel, such as gasoline, propane, charcoal or oil, burns. Sources

on your boat include gasoline engines and generators, cooking ranges, space

heaters and water heaters. Cold or poorly tuned engines produce more carbon

monoxide than warm, properly tuned engines.

Carbon monoxide is colorless, odorless and tasteless and mixes evenly

with the air. It enters your blood stream through the lungs and displaces the

oxygen your body needs. Early symptoms of carbon monoxide poison ing are

irritated eyes, headache, nausea, weakness and dizziness are often confused

with sea sickness. Prolonged exposure can lead to death.

Carbon monoxide concentrationscan be hazardous on the open deck of

a boat, on a deck with an open bimini top, in an open cockpit, on a deck

with canvas enclosures, on the decks of adjacent boats, on nearby docks,

or in any open area that is in the vicinity of an engine exhaust. The area

of concern can be a considerable distance from the engine exhaust and still be

dangerous if the prevailing wind blows the carbon monoxide into the area. Be

alert to the symptoms of carbon mon oxide poisoning described in this section.

Carbon monoxide can collect within a boatina variety of ways. Exhaust

leaks, the leading cause of death by carbon monoxide, can allow car bon

monoxide to migrate throughout the boat and into enclosed areas. Even

properly vented exhaust can re-enter a boat if it’s moored too close to a dock or

another boat, or if the exhaust is pushed back by prevailing winds. Exhaust can

also re-enter boats when cruising under certain conditions-the station wagon

eect-especially with canvas enclosures in place.

CONTROL HAZARD - Federal laws prohibit operating a boat under the

inuence of alcohol or drugs. These laws are vigorously enforced.

WARNING

!

22 - Safety

Carbon monoxide awareness and regular & proper boat main tenance and

operation are your best defenses against injury from carbon monoxide.

What To Do

1. Schedule regular engine and exhaust system maintenance

inspec tions by experienced and trained technicians.

2. Be aware that dangerous concentrations of carbon

monoxide can accumulate when a boat, generator or other

fueled device is operat ed while the boat is at a dock or seawall

or alongside another boat. Do not run the boat or equipment for

an extended time under these conditions or without continuous

monitoring. Even if your boat is die sel powered, carbon monoxide

can accumulate from proximity to other boats.

3. Keep forward-facing hatches open, even in inclement

weather, to allow fresh air circulation in accommodation

spaces. When possi ble, run the boat so that the prevailing winds

will help dissipate the exhaust.

4. Do not confuse carbon monoxide poisoning with

seasickness or intoxication. If someone on board complains

of irritated eyes, head ache, nausea, weakness or dizziness,

immediately move the person to fresh air, investigate the cause

and take corrective action. Seek medical attention, if necessary.

5. Do not let people swim in the areas near engine or generator

exhaust.

6. Install a carbon monoxide detector in each accommodation

space on your boat. Check the detectors periodically for proper

functioning.

Checklist

Each trip:

q Make sure all exhaust clamps are in place and secure.

q Look for exhaust leaking from the exhaust system components,

indicated by rust and/or black streaking, water leaks, or corroded or

cracked ttings.

q Inspect rubber exhaust hoses for burned or cracked sections. All rubber

hoses should be pliable and free of kinks.

q Conrm that water ows from the exhaust outlet when the engines and

generator are started.

q Listen for any change in exhaust sound that could indicate an exhaust

component failure.

q Test the operation of each carbon monoxide detector by pressing the

test button.

Do not operate the vessel if any of these problems exist!

Safety - 23

At least annually: (performed by a qualied marine technician)

q Replace exhaust hoses if any evidence of cracking, charring or

deterioration is found.

q Replace each water pump impeller and inspect the condition of the

water pump housing. Replace if worn. (Refer to the engine and

generator manuals for further information.)

q Inspect each of the metallic exhaust components for cracking, rusting,

leaking or looseness. Pay particular attention to the cylin der head,

exhaust manifold, water injection elbow, and the thread ed adapter

nipple between the manifold and the elbow.

q Clean, inspect and conrm the proper operation of the generator cooling

water anti-siphon valve (if equipped).

WARNING!

These Conditions May Cause Carbon Monoxide to Accumulate:

Blockage of exhaust outlets can cause carbon

monoxide to accumulate in the cabin and cockpit

area-even when the hatches, windows, portholes and

doors are closed.

Exhaust from another vessel that is docked or

anchored alongside your boat can emit poisonous

carbon monoxide gas into the cabin and cockpit of

your boat.

The station wagon eect, or backdrafting, can cause

carbon monoxide to accumulate inside the cabin,

cockpit and bridge when operating the boat at a high

bow angle or with improper or heavy loading.

The station wagon eect, or backdrafting, can also

cause carbon monoxide to accumulate inside the

cabin, cockpit and bridge when the boat is under way

using protective weather coverings.

Slow speeds or having boat stopped (idling) in the

water can cause carbon monoxide gas to accu mulate

in the cabin, cockpit and bridge. A tail wind (force

of wind entering from aft section of yacht) can also

increase accumulation.

24 - Safety

Information

To nd out more about making boating safer - including how you can prevent

carbon monoxide poisoning on recreational boats - contact:

National Marine Manufacturers Association

200 E. Randolph Drive, Suite 5100

Chicago, IL 60601-6528

www.nmma.org 312.946.6200

United States Coast Guard Oce of Boating Safety

CG Headquarters G-OPB-3

2100 Second Street SW

Washington, DC 20593

www.uscgboating.org 202.267.0984

American Boat & Yacht Council, Inc.

3069 Solomon’s Island Road

Edgewater, MD 21037-1416

www.abycinc.org 410.956.1050

!

DANGER

EXTREME HAZARD -

1. Carbon monoxide can accumulate on the open deck of a boat

or on the open deck of an adjacent boat. This accumulation can

be more concentrated if the wind direction is unfavorable or if

an open bimini top is in use.

2. Carbon monoxide can accumulate on nearby docks on in the

open air near the exhaust of any engine.

3. Carbon monoxide concentrations can be extremely high at the

transom of any boat with engine exhaust through the transom.

Never swim near the back of a boat or near any engine or

generator exhaust.

4. Never play on the swim platform or ride on the swim platform

while the engine(s) is running. Never allow anyone to hold onto

the swim platform and be dragged by the boat. There is danger

of carbon monoxide poisoning and death from drowning.

Safety - 25

Load Capacity

• The Coast Guard requires boats

less than 6.4 meters (20 feet) to

have a Certication Label stating

the maximum number of persons

and the maximum weight the boat

will handle safely under normal

conditions. ISO international

directives require a builder’s plate

on boats up to 24 meters (78.7

feet).

• Certication Label is attached to

the hull or superstructure near the

helm or transom.

• Overloading violates regulations.

Do not carry more weight or

passengers than indicated on the Certication Label.

• The number of seats is not necessarily an indication of the

number of persons a boat can carry safely.

• When operating the boat above the idle speed, carry no more

passengers than there are real, safe seats, and insist that

passengers sit down in those seats. Follow the instructions of

seating chart labels if provided.

• The presence of the Certication Label does not relieve the

owner/opera tor from responsibility for using common sense and

sound judgment.

• Overloading, improper loading and distribution of weight are

signi cant causes of accidents. Give yourself an extra margin of

safety in rough water.

Power Capacity

Do not exceed the maximum engine power rating stated on the Certication

Label attached to your boat.

Stability

• The manufacturer may provide a statement with the owner’s

informa tion packet indicating the stability and otation standards

for your boat.

• Stability may be reduced if passengers or equipment are added

to the boat. Stability is more severely reduced if the added weight

is placed on the superstructure of the boat.

• Stability is substantially reduced by loose uids or weight within

the hull. Keep bilge area as dry as possible, and close openings

in rough weather.

• It is important to know the sea and wind conditions for which your

boat is assessed to be suitable. Consult the boat manufacturer

to determine the design category for your boat: A-Ocean, B-

Oshore, C-lnshore, D-Sheltered waters.

26 - Safety

Warning Labels

Warning labels are mounted at key locations to advise you of safety pre cautions

when operating or servicing equipment. Do not remove or cover warning labels.

Replace when illegible. Contact an authorized Barletta Pontoon Boat dealer for

replacement warning labels.

Safety - 27

28 - Safety

Weather

Learn to understand weather patterns and signs of change. Bad weather and

sea conditions can cause an uncomfortable and unsafe situation. Here are a few

basic weather-related rules:

• Check the forecast and sea conditions before leaving and while

underway.

• A sudden change in wind direction or speed or an increase in

wave height indicates deteriorating weather.

• Be aware of the hazards of thunderstorms, downbursts,

microbursts, and tornados. Monitor National Weather Service

broadcasts and Coast Guard marine weather information

including small craft advisories on VHF channel 22 on your

marine radio.

• Wear a personal otation device.

• If a storm approaches, immediately seek a safe harbor.

• If a storm hits, head the bow of your boat into the wind.

• If you encounter fog, determine your position, set a safe course,

slow down and alert other boats of your presence with a sound

signal.

• The best lightning protection is a properly grounded lightning

rod that is high enough to provide a protective umbrella over

the boat. Stay clear of the rod and all attached wiring. See your

dealer for more information.

Accident Report

The U.S. Coast Guard and state agencies require a report to be led by the

operator of a boat involved in an accident involving loss of life, disappear ance,

injury requiring treatment beyond rst aid, loss of boat or property damage

exceeding $500. Contact the state boating agency where the accid ent occurs for

a copy of the state’s accident report form. In the absence of a state enforcement

agency, contact the Coast Guard oce nearest the acci dent site. Other

countries have other reporting requirements. Consult your nation’s boating law

enforcement agency. A copy of the USCG Accident Report Form is included in

the back of this manual.

Hotlines

The Coast Guard oers many pamphlets on safety and other information not

covered in this book. Contact your local Coast Guard unit or call these toll-free

safety hotlines:

• U.S. Coast Guard 1-800-368-5647, www.uscgboating.org

• Canadian Coast Guard 1-800-267-6687, www.ccg-gcc.gc.ca

Safety - 29

Minimum Required Equipment

Consult your national boating law enforcement agency.

Equipment Class A Class 1 Class 2 Class 3

(Less than

4.8 meters

[16 feet])

(4.8 to less

than 7.9

meters

{16 to less

than 20 feet])

(7.9 to less

than 12.2

meters [26 to

less than 40

feet])

(12.2 meters

to less than

19.8 meters

[40 to less

than 65 feet])

Engine

backre

ame

arrester

One approved device on each carburetor of all gasoline

engines, except outboard motors.

Bell, Whistle

Some means of making ecient sound signal,

for example, whistle or air horn.

Must carry a

whistle and

a bell audible

for .5 nautical

mile

Fire

Extinguisher

- Portable

(if no xed re

extinguishing

system is

installed in

machinery

spaces)

At least one B-1 type Coast

Guard approved portable

marine re extinguisher. (Not

required on outboard motor

boats less than 7.9 meters [26

feet] in length without

permanently installed fuel

tanks and not carrying

passengers for hire, provided

construction of boat will

not permit entrapment of

explosive or ammable gases

or vapors.)

At least two

B-1 type

Coast Guard

approved por

table marine

re extinguish

ers, or at least

one B-1 type

approved

por table

marine re

extinguisher.

At least three

B-1 type

Coast Guard

approved

porta ble

marine re

extinguishers,

or at least

one B-1 type

plus one B-1

type approved

porta ble

marine re

extinguisher.

Navigation

Lights

Required between sunset and sunrise or in reduced visibility.

Muing

Device

Ecient muing device or system to prevent excessive or

unusual engine noise.

Personal

Flotation

Devices

(PFDs)

One Coast Guard approved type I, II or Ill device for each

person aboard, plus one throwable Type IV device. Type V

device is acceptable if worn for approved use. Always wear a

PFD when boating.

Ventilation Boats with closed compartments or permanently installed fuel

tanks must be equipped with an ecient natural or mechanical

bilge ventilator or meet applicable Coast Guard construction

standards for fuel and electrical systems.

30 - Safety

Additional Recommended Equipment

A wise boater will include many of the following items:

• Visual distress signals for day and night use (required in some

areas; consult local regulations)

• Sound signal devices such as horn, bell, whistle, or gong

• Marine radiotelephone

• Compass

• Depth sounder

• Charts

• Spare keys

• Emergency position-indicating radio beacon

• Portable radio with weather band

• Waterproof ashlight

• Batteries

• Mooring lines

• Fenders

• Extra propeller

• Ground tackle (at least 2 anchors, rhode, shackles)

• Paddles or oars

• Boat hook

• Safety approved gas can, properly stowed

• Bailer

• Spare parts kit (spark plugs, fuses, etc.)

• Tool kit

• First aid kit

• Carbon monoxide detection system if your boat has an enclosed

accommodation compartment

Safety - 31

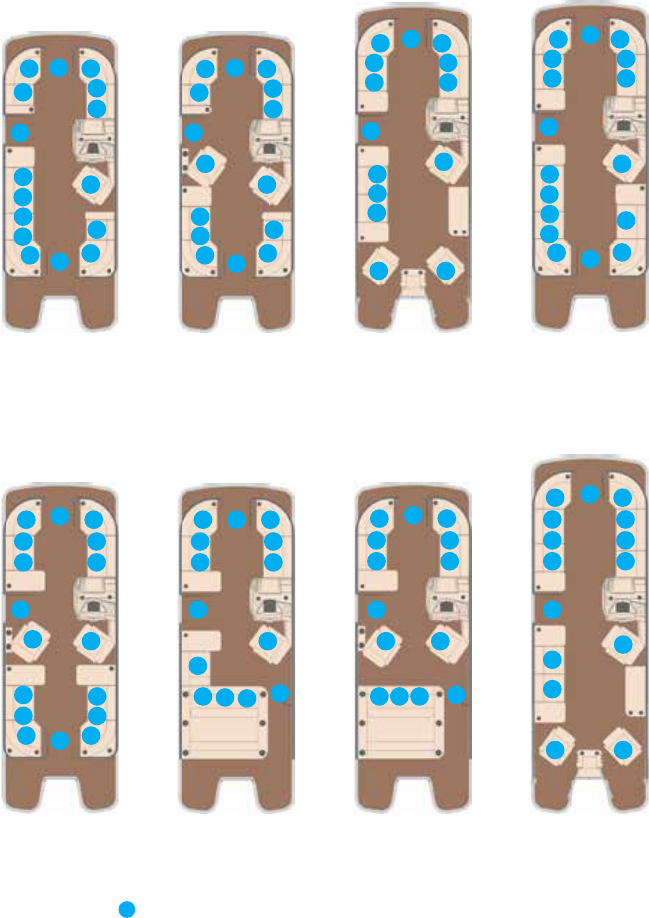

Barletta Floorplan Occupant Positions - L Class

Designated Occupant Postion - a standing or seated area with a minimum width

of 16 inches (40.6 cm) designed to be occupied at boat speeds in excess of ve

mph (4.3 kts). THESE DIAGRAMS ARE NOT PERSONS CAPACITY.

L23Q & QA

L23QC & QCA L23U & UA L23UC & UCA

L25Q & QA

= seated

L21Q L21QC L21U

32 - Safety

= seated

Barletta Floorplan Occupant Positions - L Class

L25QC & QCA L25U & UA L25UC & UCA

L25UE & UEA

Safety - 33

E20Q E20QC E22CC E22Q

E22QC E22U E22UC E24CC

= seated

Barletta Floorplan Occupant Positions - E Class

Designated Occupant Postion - a standing or seated area with a minimum width

of 16 inches (40.6 cm) designed to be occupied at boat speeds in excess of ve

mph (4.3 kts). THESE DIAGRAMS ARE NOT PERSONS CAPACITY.

34 - Safety

E24Q E24QC E24U E24UC

= seated

Barletta Floorplan Occupant Positions - E Class

Safety - 35

C20Q C20QC C22CC C22Q

C22QC C22U C22UC C24CC

= seated

Barletta Floorplan Occupant Positions - C Class

Designated Occupant Postion - a standing or seated area with a minimum width

of 16 inches (40.6 cm) designed to be occupied at boat speeds in excess of ve

mph (4.3 kts). THESE DIAGRAMS ARE NOT PERSONS CAPACITY.

36 - Safety

C24Q C24QC C24U C24UC

= seated

Barletta Floorplan Occupant Positions - C Class

Navigation - 37

Section 2

Navigation

Rules of the Road

Navigational rules are commonly called Rules of the Road. There are two types:

Inland Rules apply to vessels on United States inland waters; International

Rules apply to vessels on the high seas. Basic principles agree, but some

dierences exist. Learn and follow the rules that apply to your area.

It is impossible to establish rules for every situation. Therefore, it is important to

act prudently.

This manual is not intended to teach all the rules of navigation. It presents

a general overview, and you are strongly urged to get training before taking

command of your boat.

Understand important terminology distinctions:

• Power-Driven Vessel - A boat propelled by an engine (including

a sailboat propelled by engine and sail).

• Sailing Vessel - A boat propelled by sail only, with no engine in

operation.

• Underway - A boat not anchored, not made fast to shore and not

aground.

• Vessel Engaged in Fishing - A commercial shing boat with

gear that restricts maneuverability (does not include trolling lines

or other gear that does not restrict maneuverability).

CAUTION

!

• Follow navigation rules to avoid collisions.

• Less maneuverable boats generally have the right of way. Steer

clear of the stand-on (right-of-way) boat and pass to its stern.

• If a collision appears unavoidable, both vessels must act.

Prudence takes precedence over right-of-way rules if a crash is

imminent.

• The Rules do not relieve the give-way vessel of the obligation to

keep out of the way.

38 - Navigation

Basic Rules

Power-Driven Vessels must keep out of the way of:

• A vessel unable to maneuver or not under command

• A vessel whose maneuverability is restricted

• A vessel engaged in commercial shing

• A sailing vessel

Sailing Vessels must keep out of the way of:

• A vessel unable to maneuver or not under command

• A vessel whose maneuverability is restricted

• A vessel engaged in commercial shing

Vessels Engaged in Commercial Fishing must keep out of the way of:

• A vessel unable to maneuver or not under command

• A vessel whose maneuverability is restricted

MEETING

CROSSING

OVERTAKING

Navigation - 39

Boat Navigation Lights

Boats must display navigation lights when operating between sun set and

sunrise and during periods of reduced visibility, e.g., fog or rain, to alert

other boats to their presence and course. Although boat manufacturers

usually provide lights to comply with these rules, it is the operator’s

responsibility to know and comply with local laws.

Learn to recognize light groupings from dierent positions:

• Masthead Light - 225 degrees of visibility - white light

forward, 8 o’clock to 4 o’clock (approximate).

• Sidelight - 112 degrees of visibility - green light starboard, 12

o’clock to 4 o’clock (approximate); red light port, 8 o’clock to 12

o’clock (approximate.)

• Sternlight - 135 degrees of visibility - white light aft, 4 o’clock

to 8 o’clock (approximate).

• All-Round Light - 360 degrees of visibility - white light showing

in all directions.

• Anchor Light - 360 degrees of visibility - white all-round light.

Inland Rules exempt boats in special anchorage areas.

40 - Navigation

Some other types of navigational lights include:

• Sailboats operating under engine power must display the same

lights as other power-driven vessels.

• Sailboats under sail only must display green and red sidelights

and a white sternlight, but not a white masthead light. Boats

under sail may display two all-round lights, red over green, near

the top of the mast. Sailboats under 7 meters (23 feet) should

display such lights if possible, but if not, the boat must have an

electric torch or lighted lantern to show a white light in time to

prevent collision.

• Commercial shing vessels stopped while trawling must display a

green all-round light over a white all-round light.

• Commercial shing vessels stopped while engaged in other than

trawl ing operations must display a red all-round light over a white

all-round light.

• Towing vessels may display a yellow ashing or xed light.

• Enforcement vessels may display a ashing blue light.

• White strobe light is used as a distress signal.

Special use vessels such as public safety, pilot, dive boats and dredges have

other light requirements.

International and Inland Rules dier slightly on navigational light placement.

Understand the basics and learn the boat lights in your area. Avoid lights you do

not recognize.

Navigation - 41

Charts & Aids to Navigation

A vast expanse of open water o your bow might appear to be a go anywhere

playground or a place to become hopelessly lost. It is neither. How do you know

where to go? Just as maps and signs guide you on land, nautical charts and

buoys guide you aoat.

Nautical Charts provide vital information on water hazards and safe channels.

Several government agencies are responsible for charts for dierent types of

waterways: U.S. Army Corps of Engineers, Canadian Hydrographic Service,

National Oceanic and Atmospheric Administration, and Defense Mapping Agency.

Charts are also available from the following web sites:

www.usace.army.mil

www.nima.mil

www.charts.gc.ca

www.noaa.gov/charts.html

www.nauticalcharts.com

We strongly urge you to attend boating classes to learn charting and navigation

skills before taking the helm of your vessel. (See Introduction - Education.)

Buoys are strategically placed to keep you on course and out of hazardous

areas. Know their meaning and use them appropriately. Buoys are identi ed by

shape, color, light, and in reduced visibility by sound. There are two international

buoyage systems, one using Red Right Returning as a guide (Region B) and

the other using Green Right Returning (Region A). The follow ing map indicates

regions using each system. The illustration on the next page indicates placement

of basic navigational aids and colors for each region.

Example: Red Right Returning - when returning from sea or going up-stream,

keep red markers to starboard (right) and green markers to port (left). When

outbound, reverse the colors - red to port and green to starboard.

Buoys are sometimes not on station due to currents, heavy seas or other

conditions. Consult Local Notice to Mariners publication for information on

buoys o station and light outages. This information is available at

www.navcen.uscg.gov/lnm.

Buoyage

Regions

A & B

42 - Navigation

Environmental - 43

Section 3

Environmental Considerations

Fuel & Oil Spillage

Federal Regulations prohibit discharging fuel or oily waste in navigable waters.

Discharge is dened as any action which causes a lm, sheen or discoloration

on the water surface, or causes a sludge or emulsion beneath the water surface.

A common violation is bilge discharge. Use rags or spong es to soak up fuel

or oily waste, then dispose of it properly ashore. If there is much fuel or oil in

the bilge, contact a knowledgeable marine service to remove it. Never pump

contaminated bilge overboard. Help protect your waters.

If your boat is 26 feet or more in length, it must have a “Discharge of Oil

Prohibited” placard that is at least 5” x 8” posted in a prominent place on the

boat. This placard must say the following:

The Federal Water Pollution Control Act prohibits the discharge

of oil or oily waste into or upon the navigable waters of the United

States, or the waters of the contiguous zone, or which may aect

natural resources belonging to, appertaining to, or under the

management authority of the United States, if such discharge

causes a lm or discoloration of the surface of the water or

causes a sludge or emulsion beneath the surface of the water.

Violators are subject to substantial civil penalties and/or criminal

sanctions including nes and imprisonment.

Fill your fuel tank(s) and oil tank(s) to less than rated capacity to allow for

expansion of the liquids.

Waste Disposal

The use of Marine Sanitation Devices (MSD or head} is controlled by Federal

Law to eliminate the discharge of untreated sewage from vessels into the waters

of the United States. Discharge includes, but is not limited to, any soiling, leaking,

pouring, pumping, emitting, emptying, or dumping. If your boat is equipped with a

MSD, it must be a Certied Type I, or Type II, or Type Ill. The boat owner must be

familiar with the dierent types of MSDs and the allowable types that can be used

in the boating area.

CAUTION

!

Do not place facial tissue, paper towels or sanitary napkins in head.

Such material can damage the waste disposal system and the

environment.

44 - Environmental

• Use of Holding Tanks - If your boat is tted with a sewage

holding tank you must be knowledgeable about its operation

and maintenance, the use of a “Y” valve if one is installed, its

capacity, chemicals that are to be used, pump out procedures,

storage procedures to be followed if temperatures are below

freezing, and the location of discharge shuto valve(s).

• You must be aware of local environmental laws and you must

respect local discharge codes. Holding tanks are not to be

discharqed close to shore or in prohibited areas. Use marina

pump out facilities to empty the tank prior to leaving the marina.

Respect international regulations against marine pollution.

• Many areas prohibit overboard sewage discharge. Close and

disable ow-through waste system to prevent discharge in such

areas.

• Bag all refuse until it can be disposed of ashore. Regulations

prohibit disposal of plastic anywhere in the marine environment

and restrict other garbage disposal within specied distances

from shore.

Garbage Discharge Restrictions

The placard referenced above must contain the following information:

1. The discharge of plastic or garbage mixed with plastic into any

waters is prohibited.

2. The discharge of all garbage is prohibited in the navigable waters

of the United States, and in all other waters within three nautical

miles from the nearest marina.

NOTICE

• There is a possibility of being ned for having an operable direct

overboard discharge of waste in some waters. Closing the seacock

and removing the handle, or other means must be used to avoid ne.

• It is illegal for any vessel to dump plastic trash anywhere in the

ocean or navigable waters of the United States.

NOTICE

• If your boat is over 40 feet in length, you may be required to have a

written Waste Management Plan.

• If your boat is over 26 feet in length, you may be required to display

a placard that is 9 inches wide and 4 inches high which noties the

reader of the applicable restrictions.

• Operation of your boat in the Great lakes may require a dierent

placard.

Environmental - 45

3. The discharge of dunnage, lining, and packing materials that oat

is prohibited within 25 nautical miles of the nearest land.

4. Other unground garbage may be discharged beyond 12 nautical

miles of the nearest land.

5. Other garbage ground to less than one inch may be discharged

beyond three nautical miles of the nearest land.

6. A person who violates the above requirements is liable for

a civil penalty of up to $25,000, a ne of up to $50,000, and

imprisonment of up to ve years for each violation.

7. Regional, State, and local restrictions on garbage discharges

also may apply.

Note: Check with your dealer or the Coast Guard for clarication.

Excessive Noise

Many areas regulate noise limits. Even if there are no laws, courtesy demands

that boats operate quietly.

Local restrictions and international standards are constantly changing. It is

advisable to check with your dealer to be sure that your boat complies with the

local or international sound emission requirements that are applicable to your

boat and your particular usage area.

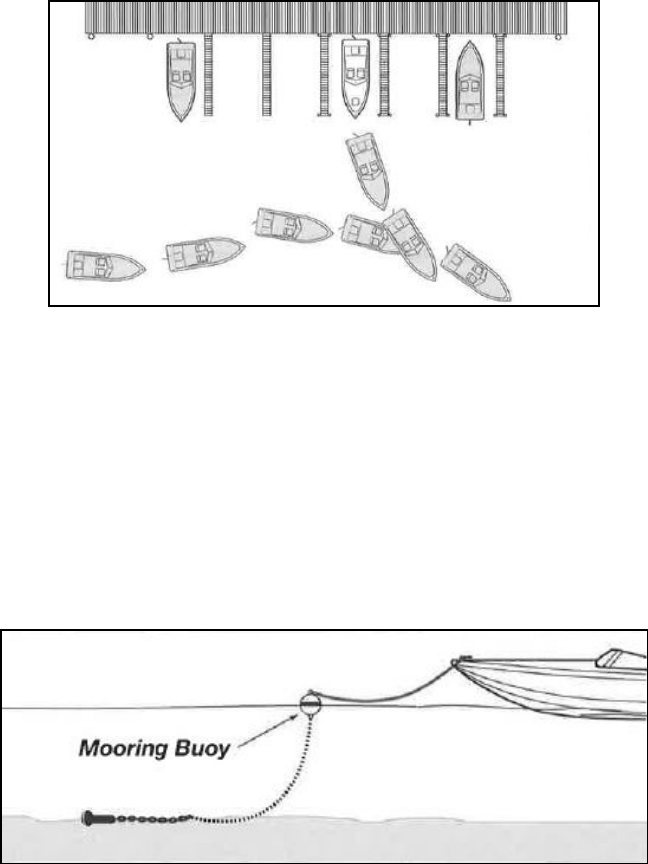

Wake/Wash

Powerboat wakes can endanger people and vessels. Each powerboat operator

is responsible for injury or damage caused by the boat’s wake. Be especially

careful in conned areas such as channels or marinas. Observe “no wake”

warnings. Some areas have no-wake or speed limit zones for other reasons,

such as protection of wildlife. The boat operator must comply with these added

restrictions.

Exhaust Emissions

Enclosed cabins or cockpits may accumulate carbon monoxide. You can be

overcome by fumes from your own engine or from neigh boring boats. Ensure

continuous movement of fresh air. Install one or more carbon monoxide detectors

in boat’s enclosed cabin or cockpit. Exhaust emissions can accumulate in

an open boat with only an open bimi ni top installed, on the open decks and

especially on the swim platform or the aft deck. Ensure continuous airow in this

situation.

CAUTION

!

Reduce speed in congested waterways.

46 - Environmental

Paint, Cleaning Agents & Other Substances

!

DANGER

EXTREME HAZARD - Ensure adequate ventilation. Gasoline engines

produce carbon monoxide gas (CO). Prolonged exposure can cause

serious injury or death. Depending on the concentration of CO in an

area inside or outside a boat, even brief exposure can cause serious

injury or death. To reduce CO accumulation, increase air movement

by opening windows or adjusting canvas. The following conditions

require special attention:

NOTICE

Refer to cleaning product specications and directions before use.

EXPLOSION/FIRE HAZARD - Ventilate when painting or cleaning.

Ingredients may be ammable and/or explosive.

WARNING

!

Environmental - 47

Consult your marine dealer about environmental regulations before painting the

hull.

Common household cleaning agents may cause hazardous reactions. Fumes

can last for hours, and chemical ingredients can attack people, property and

the environment. Avoid products containing chlorine, phosphates, and non-

biodegradable ingredients.

Anti-freeze used in the boat’s engine(s) should be propylene glycol instead of the

more common ethylene glycol, so that potential spillage will not harm wildlife.

48 - Environmental

Emergency Procedures - 49

Section 4

Emergency Procedures

The time to think about emergencies is before they happen. Plan ahead. Know

what to do before you encounter any of these situations. Wear a PFD when

boating.

Explosion & Fire

Explosion

• If explosion seems to be imminent, put on PFDs, grab distress

signals and survival gear, and immediately abandon ship.

Fire

• Turn o engines, generators, stoves and blowers. Extinguish

smoking materials.

• Fixed re suppression system, if equipped, has heat sensors that

automatically ood machinery space with a re extinguishant.

Allow extinguishant to “soak” compartment for at least 15 minutes

to cool hot metals or fuel before cautiously inspecting re area.

Have portable re extinguishers ready. Do not breathe fumes or

vapors caused by the re or extinguishant.

• If no xed reghting system is installed and re is in engine

compartment, discharge portable re extinguishers through

engine compartment access plate, if equipped. Do not open

engine hatch as this feeds oxygen to the re.

EXPLOSION/FIRE/ASPHYXIATION HAZARD

• Open ame cooking appliances consume oxygen. This can

cause asphyxiation or death.

• Maintain open ventilation.

• Liquid fuel may ignite, causing severe burns.

• Use fuel appropriate for type of stove.

• Turn o stove burner before changing the fuel source.

• Do not use stove for comfort heating.

FIRE/ASPHYXIATION HAZARD - Use special care with ames or high

temperatures near urethane foam, if used in construction of your boat.

Burning, welding, lights, cigarettes, space heaters and the like can

ignite urethane foam. Once ignited, it burns rapidly, producing extreme

heat, releasing hazardous gases and consum ing much oxygen.

WARNING

!

50 - Emergency Procedures

• If you have access to re, direct contents of extinguishers at base

of ames, not at the top.

• Throw burning materials overboard if possible.

• Move anyone not needed for reghting operations away from

the ames.

• Signal for help.

• Put on PFDs, grab distress signals and survival gear, and

prepare to abandon ship.

The boat owner/operator shall:

• Know the location of the re extinguishers and their capacities.

• Have re extinguishing equipment checked at the intervals

specied on the equipment.

• Replace portable re extinguishers, if expired or discharged, by

devices of identical re ghting capacity.

• Have xed re extinguishing system(s) relled or replaced when

expired or discharged.

• Ensure that re ghting equipment is readily accessible.

• Inform members of the crew about the location and operation of

the re ghting equipment.

• Keep the bilges clean and free from fuel and gas vapors.

• Replace parts of the re ghting installation with matching

components.

• Keep combustible materials away from the open ame devices.

• Never stow combustible material in the engine spaces.

• Identify exits from the boat.

The boat owner/operator shall never:

• Obstruct exits.

• Obstruct safety controls.

• Obstruct portable re extinguishers.

• Leave the craft unattended when appliances are in use.

• Use gas (LPG) lights on the boat.

• Fill fuel tanks or gas (LPG) bottles when machinery is running.

• Modify any of the craft’s systems.

• Smoke while fueling or handling LPG.

Abandoning Ship

• When clear of danger, account for all who were on board, and

help those in need.

• Use distress signal.

• Keep everyone together to make rescue easier.

BURN HAZARD - Swim against the current or wind if you abandon

ship. Leaking fuel will oat with the current and may ignite.

WARNING

!

Emergency Procedures - 51

Flooding, Swamping or Capsizing

• STAY WITH THE BOAT! A boat will usually oat even if there is

major hull damage. Rescuers can spot a boat much easier than a

head bobbing in water.

• Signal for help.

Collision

• Account for everyone on board.

• Check for injuries.

• Inspect structural damage.

• Reduce ooding.

• Signal for help.

• STAY WITH THE BOAT!

Grounding

Action depends on how hard the boat hits bottom and whether the boat remains

stranded. If it is a simple touch, you may need only to inspect the hull. If you are

aground, assess the situation before reacting. In some cases, throwing the boat

into reverse can cause more damage.

Basic Guidelines

• Check for leaks. If water is coming in, stopping the ow takes

priority over getting free.

• Inspect damage to hull, propulsion and steering systems.

• Determine water depth all around the boat and type of bottom

(sand, mud, rocks, etc.). This will help you decide which way to

move the boat.

• Determine if tide, wind or current will drive the boat harder

aground or will help free it.

Leaks

• Immediately switch on bilge pumps.

• Assign crew to operate manual pumps if needed.

• Check extent of leaks.

• If boat is taking on water, have someone take the helm while you

manage damage control.

• Slow or stop to minimize inow. However, if you can keep a hole

above water by maintaining speed, do so.

• If possible, patch the outside with whatever material is available

(tape or plastic for example). Also, try to stop the leak from the

inside by stung rags, clothing, cushions or any material that will

slow or stop the leak.

52 - Emergency Procedures

Towing

A recreational boat towing another is usually a last resort because of pos sible

damage to one or both boats. The Coast Guard or a private salvage company

is better equipped. A recreational boat may assist by standing by, and possibly

keeping the disabled boat’s bow at a proper angle until help arrives. Only when

conditions are ideal-that is, seas are calm, disabled boat is small, and one or

both skippers know correct technique-should a recreational boat tow another.

Towing Vessel

• Take care that your boat will not run aground, if attempting to tow

a grounded boat.

• Pass the towline to the disabled boat, since the towing boat is

more maneuverable.

• Use double-braided or braid-on-braid line. Never use three-

strand twist ed nylon; it has too much elasticity and can snap back

dangerously.

• Fasten the towline as far forward as possible on the upwind or

upcurrent side of the towing boat. Fastening it to the stern will

restrict maneuverability of the towing boat.

• If possible, use a bridle.

• Move slowly to prevent sudden strain on slack line.

• Be ready to cast loose or cut the line if the towing situation

becomes hazardous.

Vessel Being Towed

• Attach the towline to the stern eye or bow eye. Never use a

mooring cleat for towing!!!!!

• If the boat has eyebolts in the transom for pulling skiers, a towline

may be attached to a small bridle hooked to both eyebolts.

• If it is necessary to be towed after being freed, keep someone

aboard the boat to steer.

Both Vessels

• If you attach the towline to a tting, be sure that the tting is

through bolted and reinforced with a backing plate. Never use a

mooring cleat for towing!!!!!

• Creating a bridle with a line around the hull or superstructure will

dis tribute the load over a wide area; pad pressure points. This

technique can be used on both the towing and towed boat.

PERSONAL INJURY HAZARD - Towing or being towed stresses the

boats hardware and lines. Failure of any part can seriously injure

people or damage the boats.

WARNING

!

Emergency Procedures - 53

• Keep lines clear of propellers on both boats.

• Keep passengers on both boats clear of the towline that is pulled

taut.

• Never hold a towline while it is feeding out or after it is pulled taut.

Person Overboard

• Immediately sound an alarm and keep pointing to the person

over board.

• Throw a life preserver even if the person is wearing a PFD. It will

serve as a marker.

• Immediately stop or slow the boat, then circle toward the person.

• Keep person overboard on helm side so operator has the person

constantly in sight.

• Approach from downwind and move alongside into the wind for

pickup.

• When almost alongside, stop the engine in gear to prevent

dangerous propeller “windmilling.”

• As part of your emergency plan, consider what to do if you were

alone and fell overboard (e.g., wear PFD, keep signal device in

PFD, attach emergency stop switch lanyard to yourself).

• Be sure that there is a functional reboarding device or procedure

that will enable the person overboard or yourself to get back on

board the boat unassisted.

• Be sure that all passengers on board know the details of the

reboarding procedure and the operation of the equipment

required.

Drowning

• If a person is drowning, follow the standard lifesaving procedure.

Reach to pull the victim to safety. If they cannot be reached,

throw a life-saving device to them. Swim to rescue a drowning

victim only as a last resort. (Reach-Throw-Go)

• Immediate resuscitation is critical! At least two people on board

should be certied in CPR.

• Keep the victim warm.

• Use care in handling. Spinal injury may exist if the victim fell

overboard.

• Signal for help and/or take the victim to shore for medical

assistance.

Medical Emergency

In an emergency, you may be far from professional medical assistance. Be

prepared. Take a rst aid course, and carry a rst aid kit. Be aware of special

conditions that may aect anyone on board. Become familiar with the eects of

fatigue and hypothermia so that you can respond to these emergencies properly.

54 - Emergency Procedures

Carbon Monoxide

Carbon monoxide is an odorless, colorless, extremely toxic gas. Symptoms of